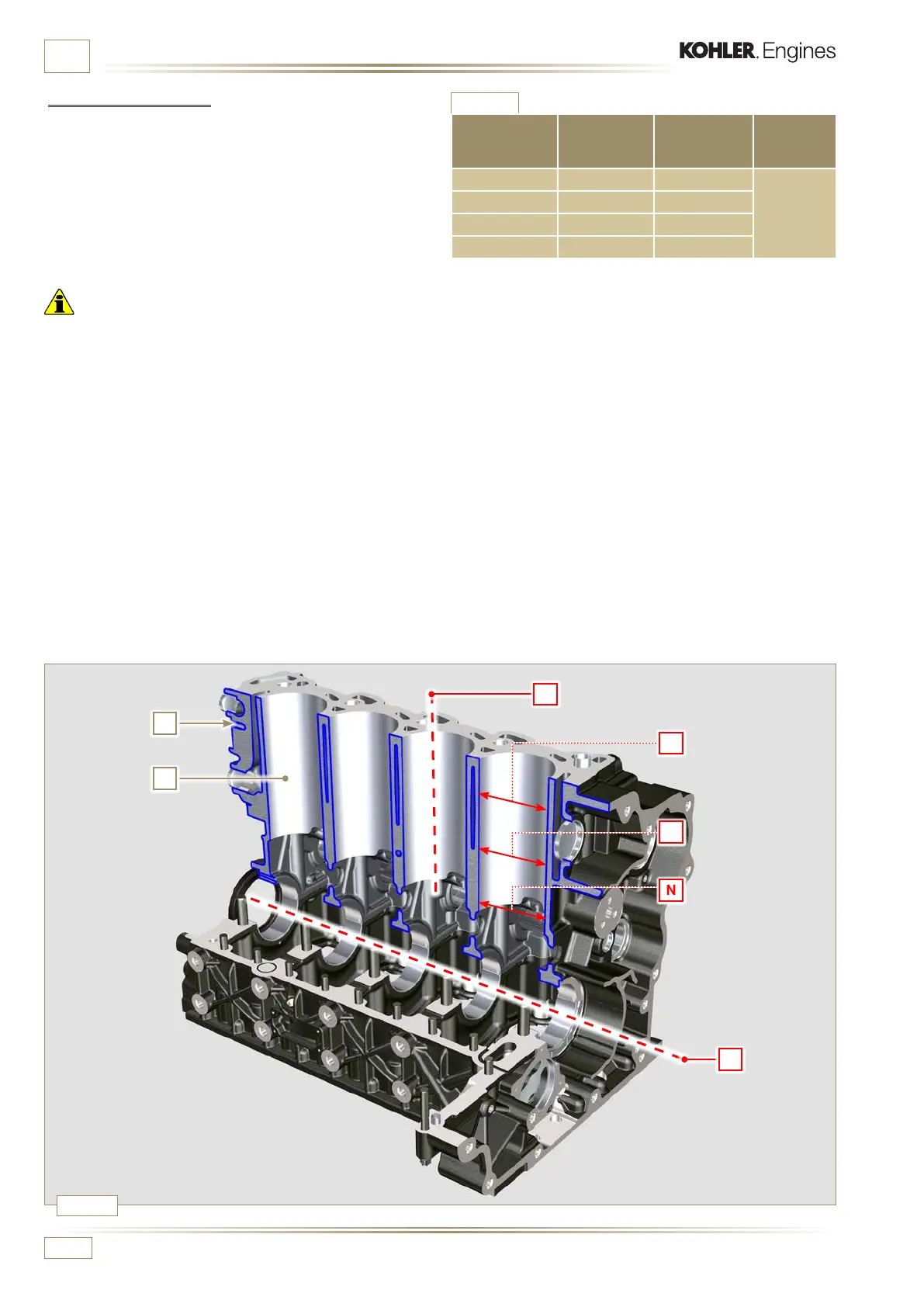

92

J

M

N

F

G

H

L

Fig. 8.2

Tab. 8.1

ED0053030410

INFORMATION ABOUT OVERHAULING

8.2.2 Cylinder check

Position crankcase G onto a workbench.

With a dial gauge, measure the diameter in correspondence to

points J-M-N (Fig. 8.2) lengthwise and diagonally with regard

to axis H of the crankshaft.

If ovalisation or wear detected in a single point in J-M-N is

greater than +0.05 mm with regard to the value in Tab. 8.1, you

are required to perform grinding operations on all cylinders F.

Refer to Tab. 8.1 to establish the clearance value of cylinders

subjected to grinding operations.

Important

• Grinding is prohibited before 10000 h of operation on all

engines provided with an EPA name plate (refer to Par. 1.3).

• The grinding involved is of +0.20, +0.50 and + 1 mm.

• Cylinder grinding operations must observe KOHLER

SPECIFICATIONS - cod. ED0035612500.

• Grinding must be strictly performed on all cylinders F.

Tab. 8.1 d e t a i l s t h e d i m e n s i o n a l v a l u e s o f n e w c o m p o n e n t s o n l y.

(1)

The increase of +0.20 mm, may already be present on the

engine.

Grinding values

PISTON

Ø CYLINDER

(± 0.007 mm)

Ø PISTON

(± 0.007 mm)

CLEARANCE

VALUE (mm)

STD 96.010 95.950

0.046 - 0.074

+0.20

(1)

96.210 96.150

+0.50 96.510 96.450

+1.00 97.010 96.950

Loading...

Loading...