91

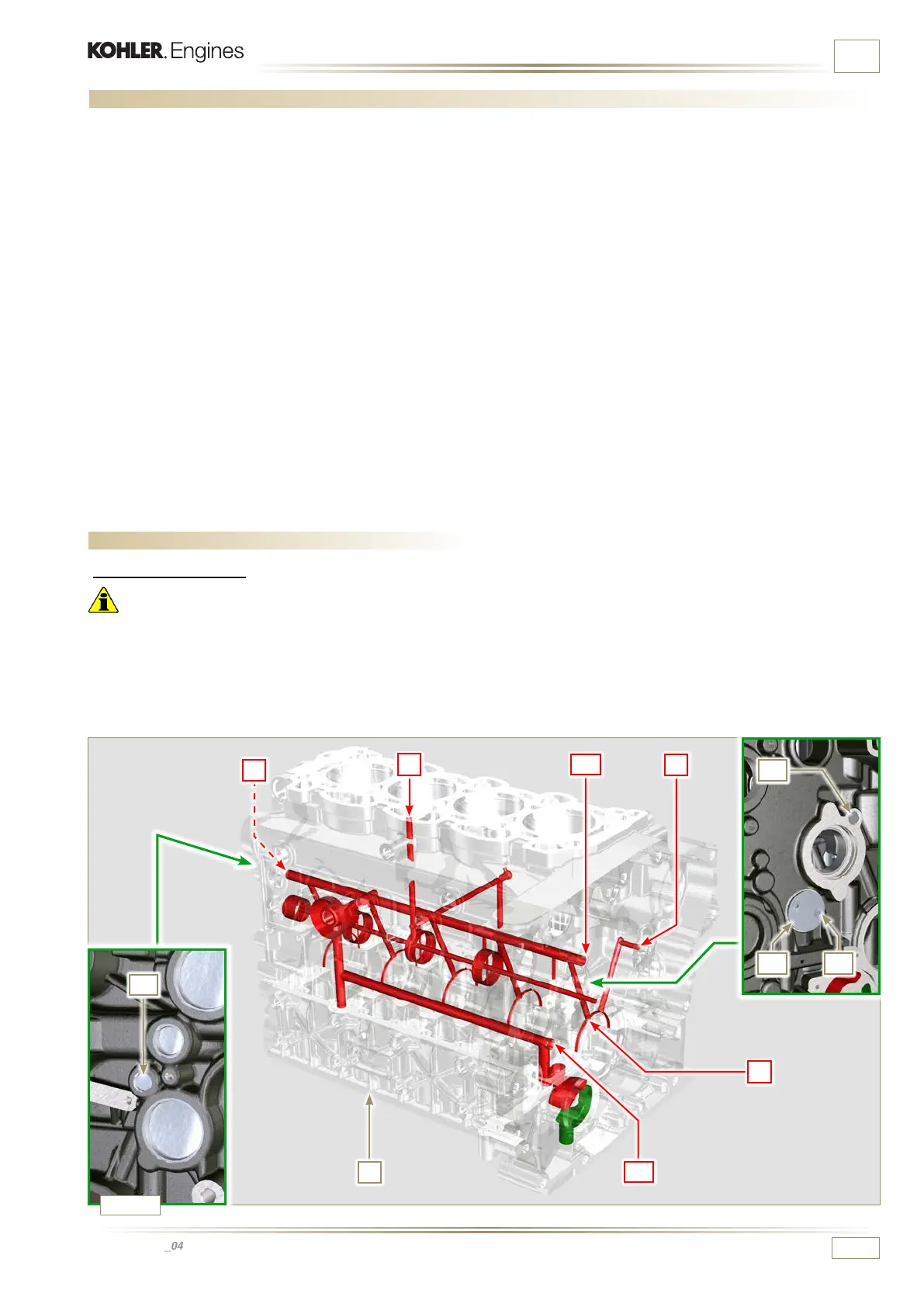

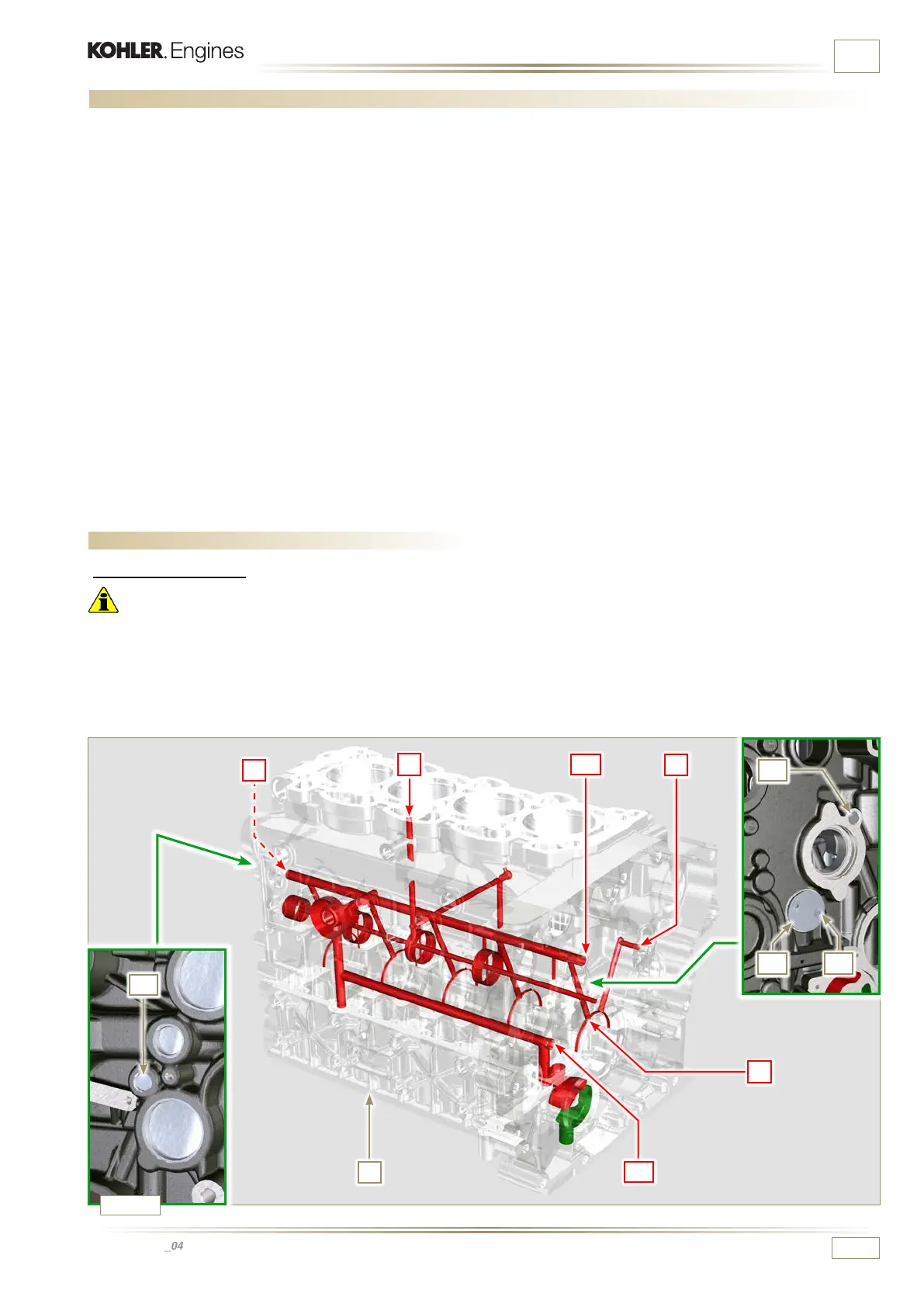

Fig. 8.1

A B1

D

C

B

B1

G

A1

A2

A3

A3

ED0053030410

INFORMATION ABOUT OVERHAULING

8.1 Recommendations for overhauls and tuning

• The information is laid out in sequence, according to

operational requirements, and the intervention methods have

been selected, tested and approved by the manufacturer's

technicians.

• This chapter describes procedures for checking, overhauling

and tuning units and/or individual components.

NOTE: To easily locate specic topics, the reader should refer

to the analytical index or chapter index.

• Before any intervention, the operator should lay out all

equipment and tools in such a way as to enable him to carry

out operations correctly and safely.

• The operator must comply with the specific measures

described in order to avoid errors that might cause damage

to the engine.

• Before carrying out any operation, clean the units and/or

components thoroughly and eliminate any deposits.

• Do not wash the components with steam or hot water. Use

suitable products only.

• Do not use flammable products (petrol, diesel, etc.) to

degrease or wash components. Use suitable products only.

• Apply a layer of lubricant over all surfaces of all disassembled

components to protect them against oxidation.

• Check the integrity and state of wear of all disassembled

components in order to ensure good working condition of

the engine.

• When indicated, some components are to be replaced in pairs

or together with other parts (e.g. crankshaft half-bearings/

connecting rod, piston complete with rings and gudgeon pin,

etc.).

• When indicated, some grinding operations are to be carried

out in series (e.g. grinding of cylinders, crankpins, journals,

etc.).

8.2 Crankcase

8.2.1 Oil line check

Important

• Replace and assemble the conical cap A3 in hole B, B1

(tightening torque at 30 Nm), after having performed cleaning

operations.

1 - Remove capscrews A1 and remove plate A2 with its

gasket.

Use a pipe cleaner in access points A, B, B1, C, D to clean

the oil ducts of crankcase G.

Use compressed air to eliminate any residues.

Loading...

Loading...