122

8

_07

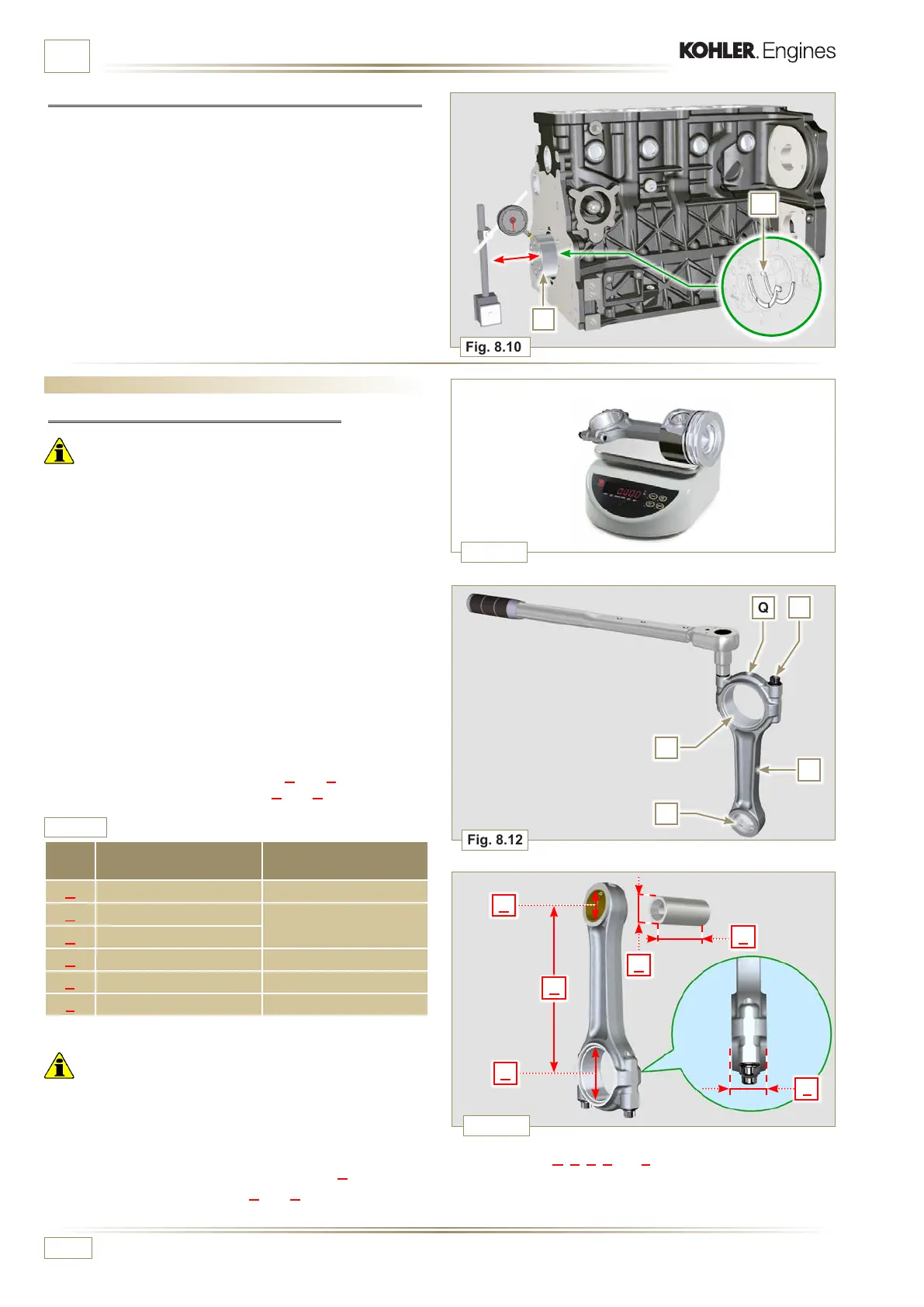

Fig. 8.12

Fig. 8.13

B

C

F

D

Q

R

T

S

P

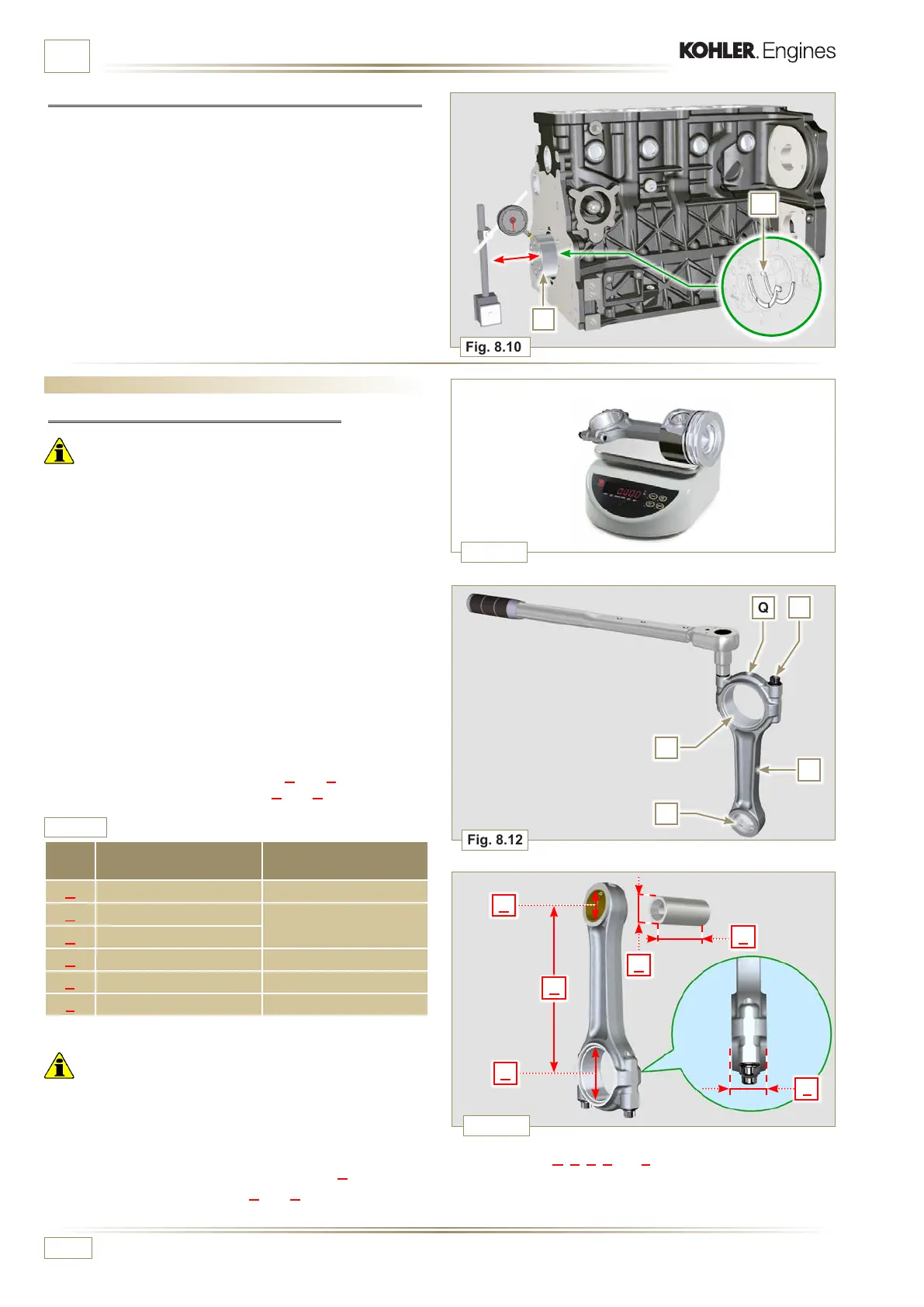

Fig. 8.10

A

E

D

E

Fig. 8.11

ED0053029590

INFORMATION ABOUT OVERHAULING

8.5 Connecting rod - piston assembly

8.5.1 Connecting rod dimensions check

Important

• Before assembling the c onnec ting ro d and pistons (Par. 9. 3.7

and 9.3.8), check that the difference in weight between the

complete connecting rod and piston units do not exceed 8 gr

to prevent weight imbalances during rotation of the crankshaft

and consequent damage.

• Mark some references on the connecting rods, caps Q, pistons

and gudgeon pins to prevent unintentionally confusing the

components during assembly. Failure to do this may result in

engine malfunctions..

• Connecting rod half-bearings S must be replaced at each

assembly.

Check that the contact surfaces are perfectly clean and intact.

Assemble the connecting rod cap Q to the connecting rod with

the half-bearings S and tighten capscrews P (tightening torque

at 25 Nm).

With a dial gauge, measure diameters B and D.

The MAX allowed value of wear for B and D is 0.06 mm.

Tab. 8.6

REF. DIMENSIONS (mm)

CLEARANCE

VALUE (mm)

A 169.980 - 170.020

B 30.020 - 30.030

0.025 - 0.030

C 29.995 - 30.000

D 54.035 - 54.066

E 67.70 0 - 68.000

F 29.750 - 29.790

Important

• Tab. 8.6 details the dimensional values of new components

only.

• Check that the connecting rod and crankshaft half-bearings

are coupled properly.

• Refer to the warnings in Par. 8.4.1 for value D decreased.

• If the clearance value between B and C is not observed, you

are required to replace bearing R (Fig. 8.12).

8.4.2 Checking the axial clearance of the crankshaft

Perform the operations described in Par. 9.3.5 e 9.3.6.

Using a dial gauge, measure the axial shift of crankshaft E.

Axial shift must be a MIN of 0.18 mm and MAX 0.38 mm..

If the values measured do not correspond, replace shoulder

rings D.

Measure value A, C, D, E and F and confront them with those

described in Tab. 8.6.

If the measured values do not follow those described in Tab.

8.6, replace connecting rod T.

Loading...

Loading...