126

8

_07

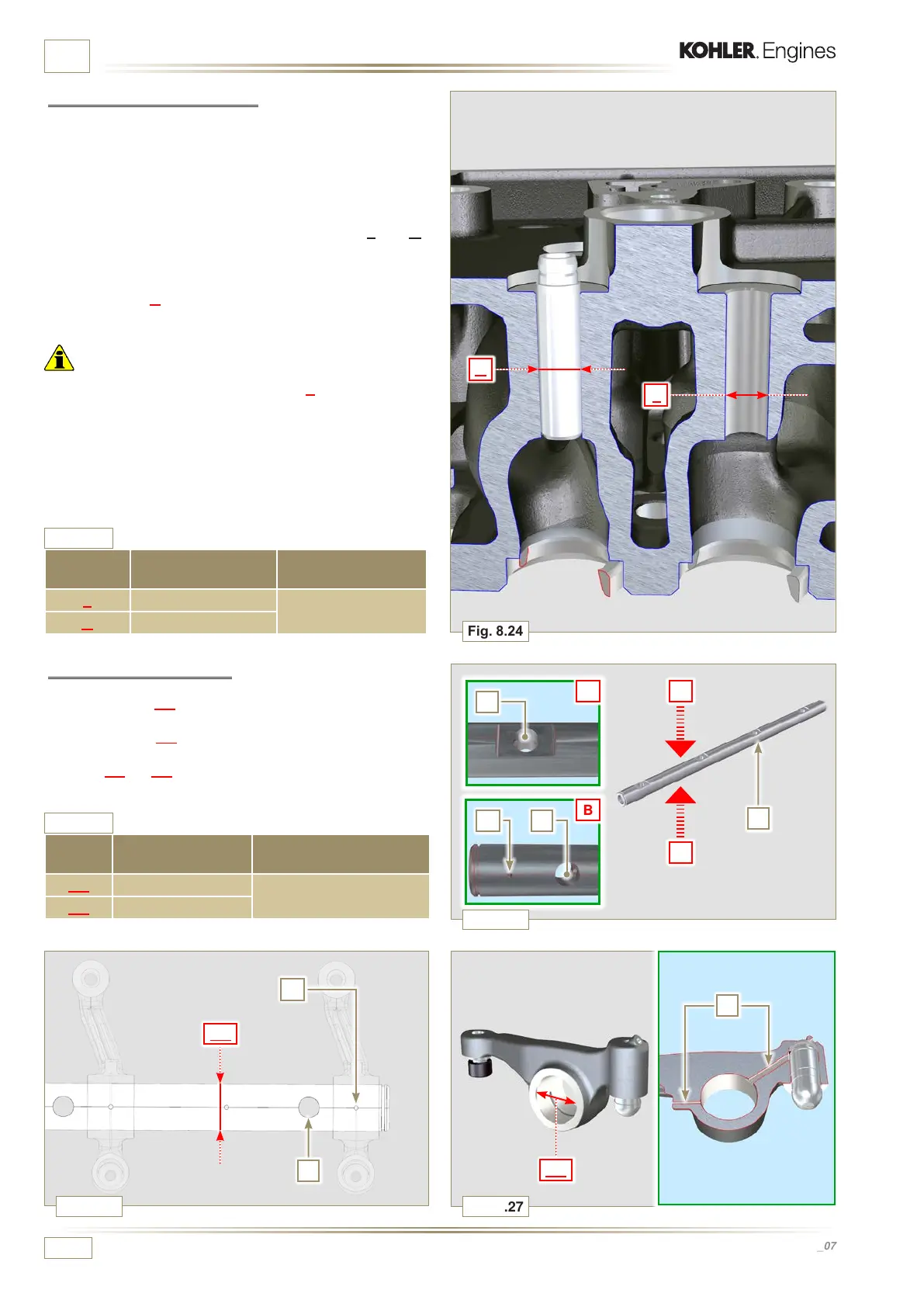

Fig. 8.24

M

L

AA

B

B

N

L

M

M

N

N

N

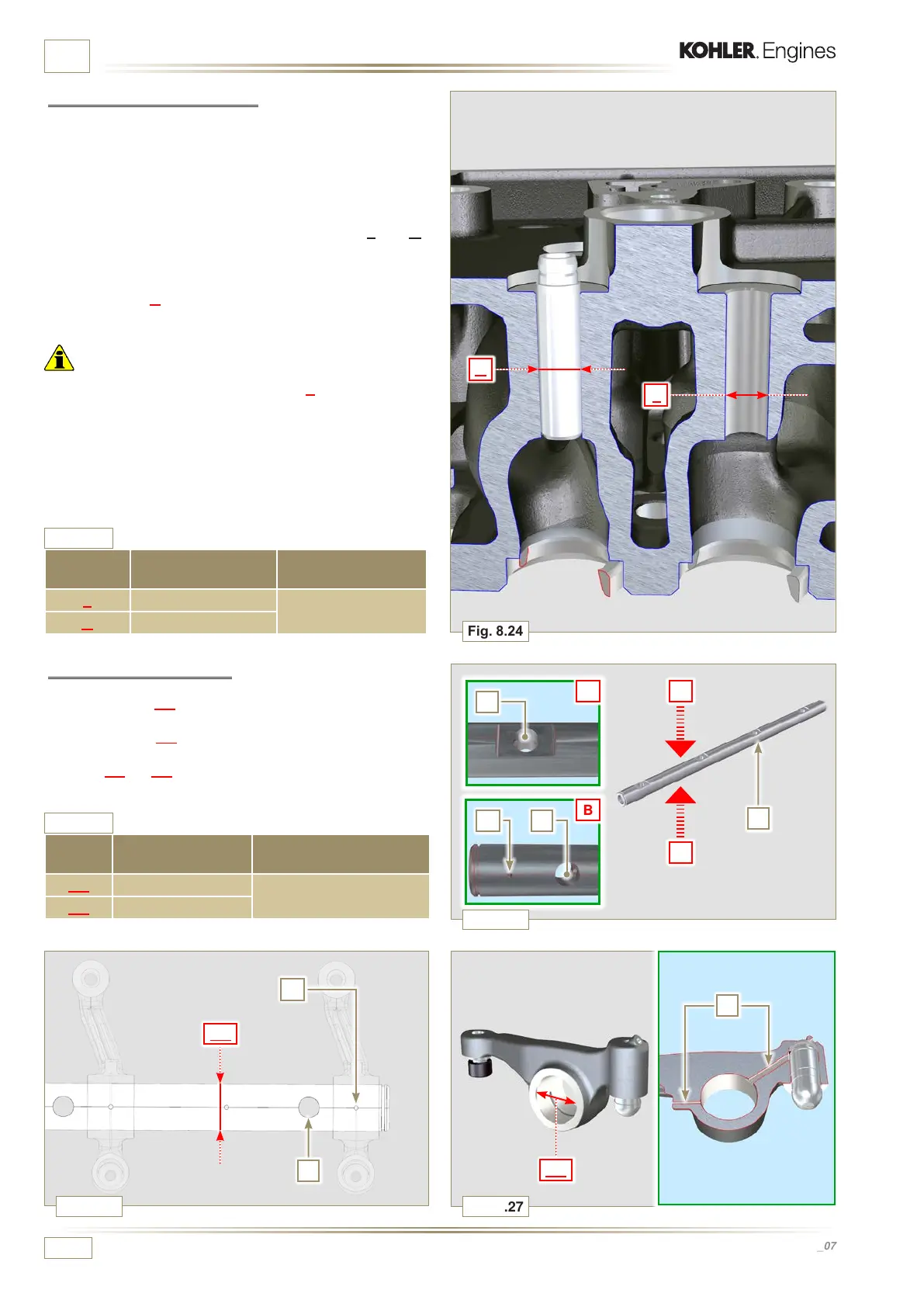

Fig. 8.25

Fig. 8.26

Fig. 8.27

W1

W2

ED0053029590

INFORMATION ABOUT OVERHAULING

8.6.5 Valve guides replacement

The intake and exhaust guides are both made out of grey

iron with pearlitic phosphoric matrix and they have the same

dimensions:

The guides are press-t assembled; assembly is possible by

cooling the guides with the aid of liquid nitrogen.

Before assembling a new guide, measure value L and M,

calculate the press-t value, which must observe the values

in Tab. 8.11.

Observe values G from surface F when assembling guides H

(Tab. 8.10 - Fig. 8.23).

Important

• The guides must be worked for value E (Tab. 8.10 - Fig.

8.23) after driving. Contact a rectification workshop for such

operations.

Guide valve - guide seat valves dimensions

Tab. 8.11

REF. DIMENSIONS (mm)

PRESS-FIT VALUE

(mm)

L 10.000 - 10.015

0.030 - 0.054

M 10.045 - 10.054

REF. DIMENSIONS (mm)

CLEARANCE VALUE

(mm)

W1 19.985 - 20.005

0.035 - 0.076

W2 20.040 - 20.061

Tab. 8.12

8.6.6 Rocker arm check

Measure values W1 in correspondence with holes M located

on rocker arm gudgeon L (seen from B in Fig. 8.25).

Measure values W2 (Fig. 8.27).

Based on the values measured, calculate the clearance

between W1 a n d W2, which is to observe the values in Ta b . 8 .1 2 .

Check that all oil pipes N and M are free from impurities or

obstructions.

Loading...

Loading...