127

8

_07

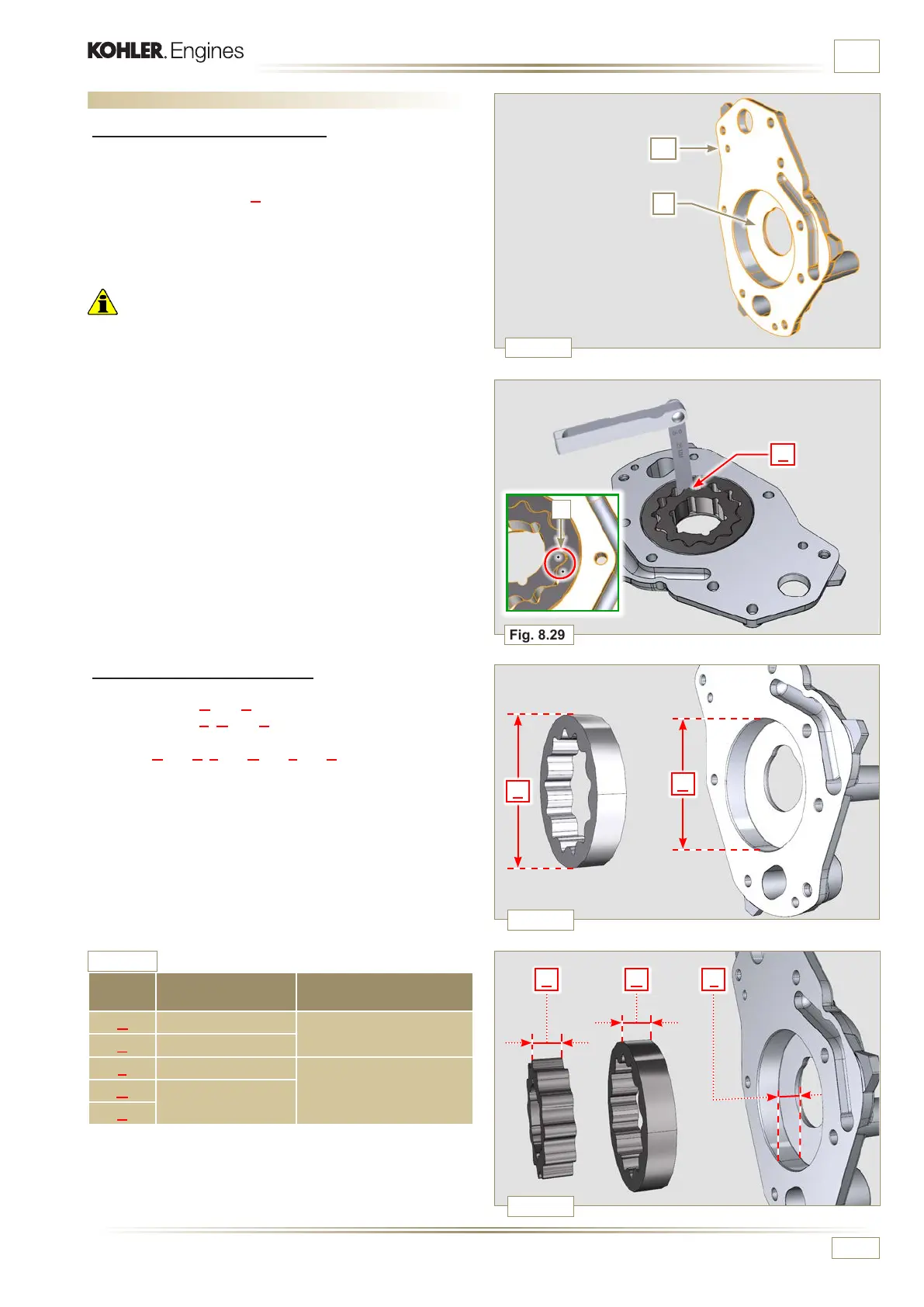

Fig. 8.29

A

B

C

D

Fig. 8.28

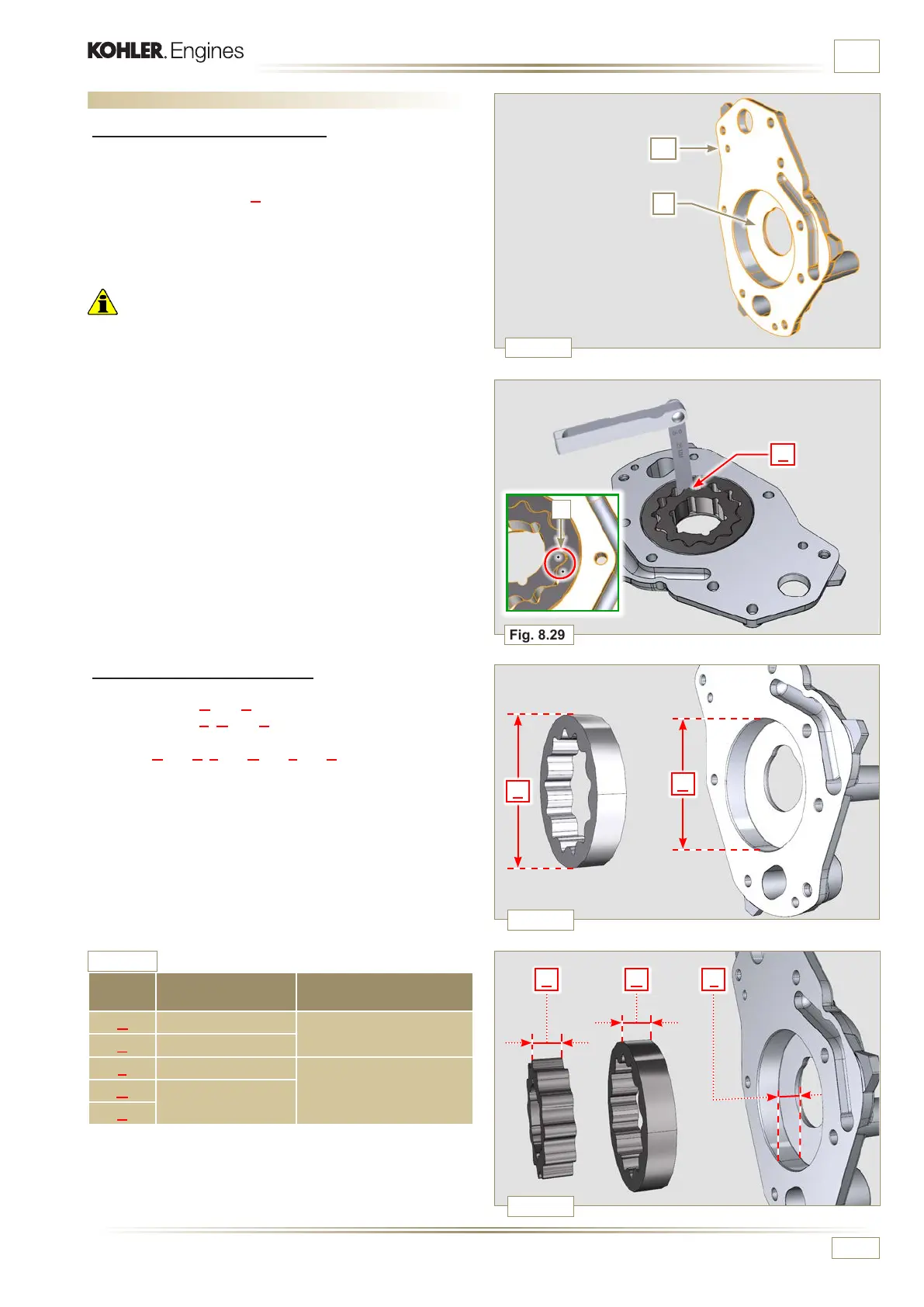

Fig. 8.30

Fig. 8.31

G

H

LMN

ED0053029590

INFORMATION ABOUT OVERHAULING

8.7 Oil pump check

8.7.1 Dimensional and visual check

Perform the operations described in Par 7.8.1 and 7.8. 4.

Measure clearance value B between the rotor teeth, the value

of allowable wear is MAX 0.28 mm.

Clean all the components thoroughly, check that the work

surfaces C of the rotors and pump body are not worn.

Important

• Should the results from checks carried out not be in

accordance with the conditions described, replace the timing

system carter together with the oil pump.

On assembly, references A must be visible.

8.7.2 Rotors clearance check

Measure values G and H (Fig. 8.30).

Measure values L, M and N (Fig. 8.31).

According to the values measured, calculate the clearance

between G and H, L and M and L and N which are to observe

the values in Tab. 8.13.

For assembly, carry out the operations described from Par.

9.11.3 to Par. 9.11.4.

REF.

DIMENSIONS

(mm)

CLEARANCE VALUE

(mm)

G 82.820 - 82.855

0.032 - 0.075

H 82.500 - 82.540

L 15.500 - 15.525

0.036 - 0.086

M

15.464 - 15.489

N

Tab. 8.13

Loading...

Loading...