9

135

_07

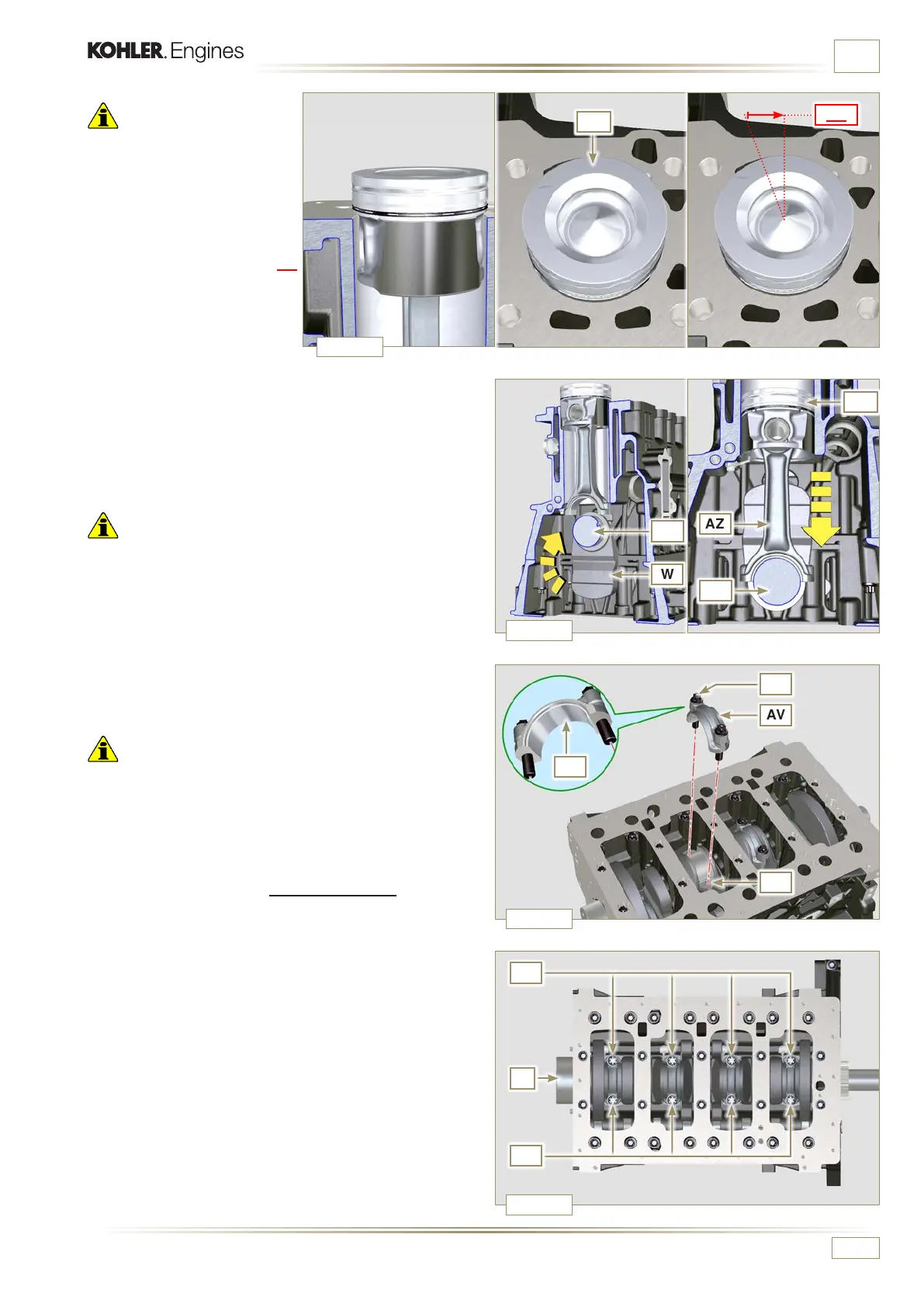

Fig. 9.23

AU

AU

Fig. 9.22

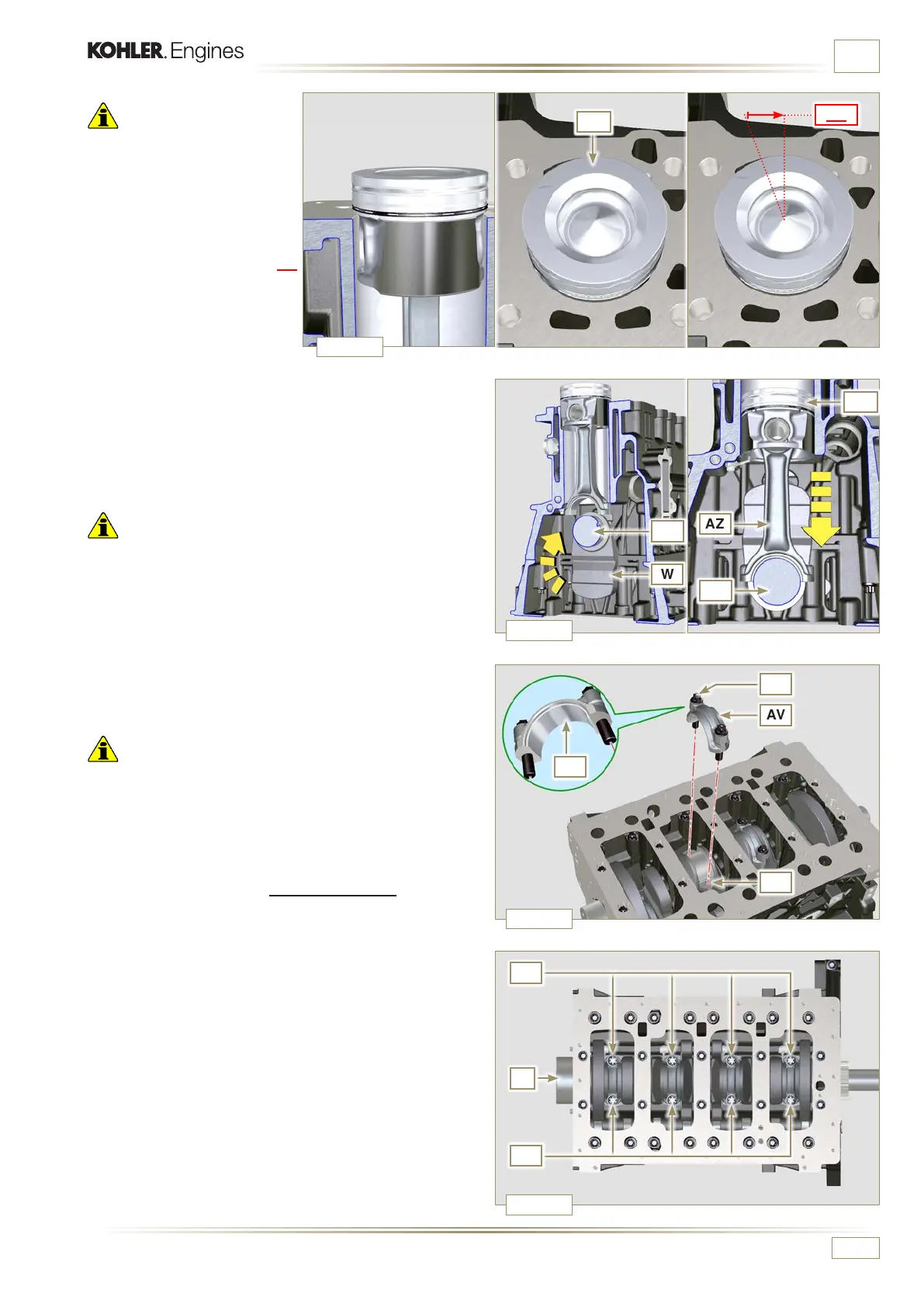

AV

AZ

AU

AS

Fig. 9.21

W

W

AQ

AZ

BG

BG

BR

Fig. 9.20

AQ

ED0053029590

ASSEMBLY INFORMATION

Important

• Leave the ring compressor

assembled on the piston

6 - Push piston AQ downwards

without introducing the

segments in the cylinder,

rotate piston AQ by 10° in a

clockwise direction (value BR

– correct assembly position).

7 - Push the piston AQ downwards by centering the crankpin

BG with the connecting rod AZ.

8 - Turn the crankcase on support to assemble the con rod

capp on cylinder 1 and 4.

9

- Check that the half-bearing AS is mounted correctly on the

connecting rod cap AV.

Important

• Check that the break levels of connecting rod cap AV coincide

perfectly onto connecting rod AZ before screwing on and

tightening capscrews AU.

10 - Couple the connecting rod cap AV to the connecting rod

AZ using the marks made at disassembly (Par. 7.15.2 e

7.15.5).

11 - Screw in the screws AU.

12 - Repeat the operations from 1 to 10 for each cylinder.

Important

• Failure to adhere to the assembly procedures may

compromise the functionality of the engine, and also cause

damage to persons and property.

13

- Tighten the screws AU, alternately, strictly following the

tightening torques indicated.

Tightening sequence of screws Torx M10x1:

1° CYCLE - with a torque of 40 Nm;

2° CYCLE - with a torque of 85 Nm;

14 -

Check that the connecting rods have axial play and the

crankshaft W rotates smoothly.

NOTE:

After the check carried out at point 14, position the

shaft W with the rst cylinder to TDC.

Loading...

Loading...