9

143

_07

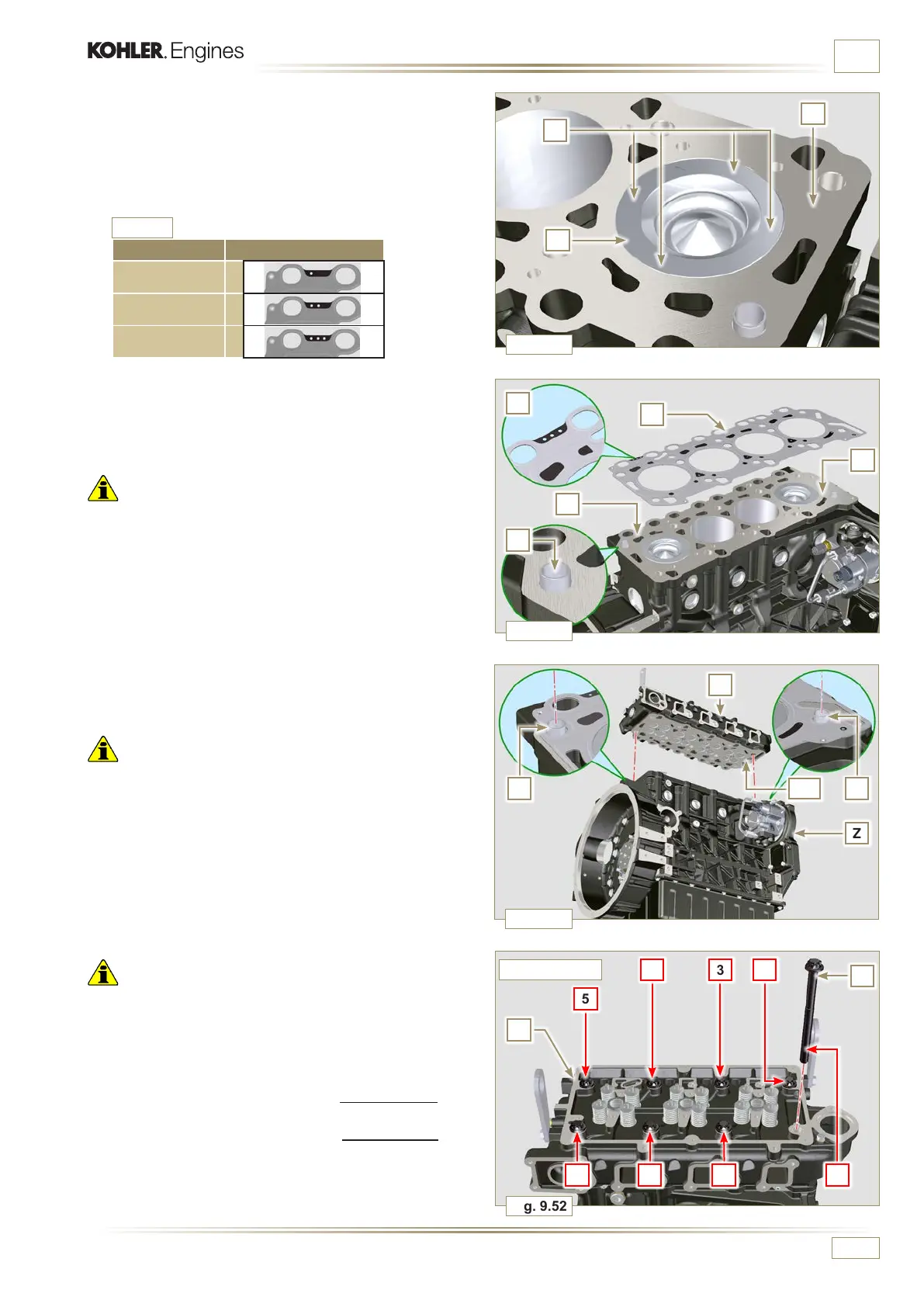

Fig. 9.52

1

2

5

4

3

6

7

8

V

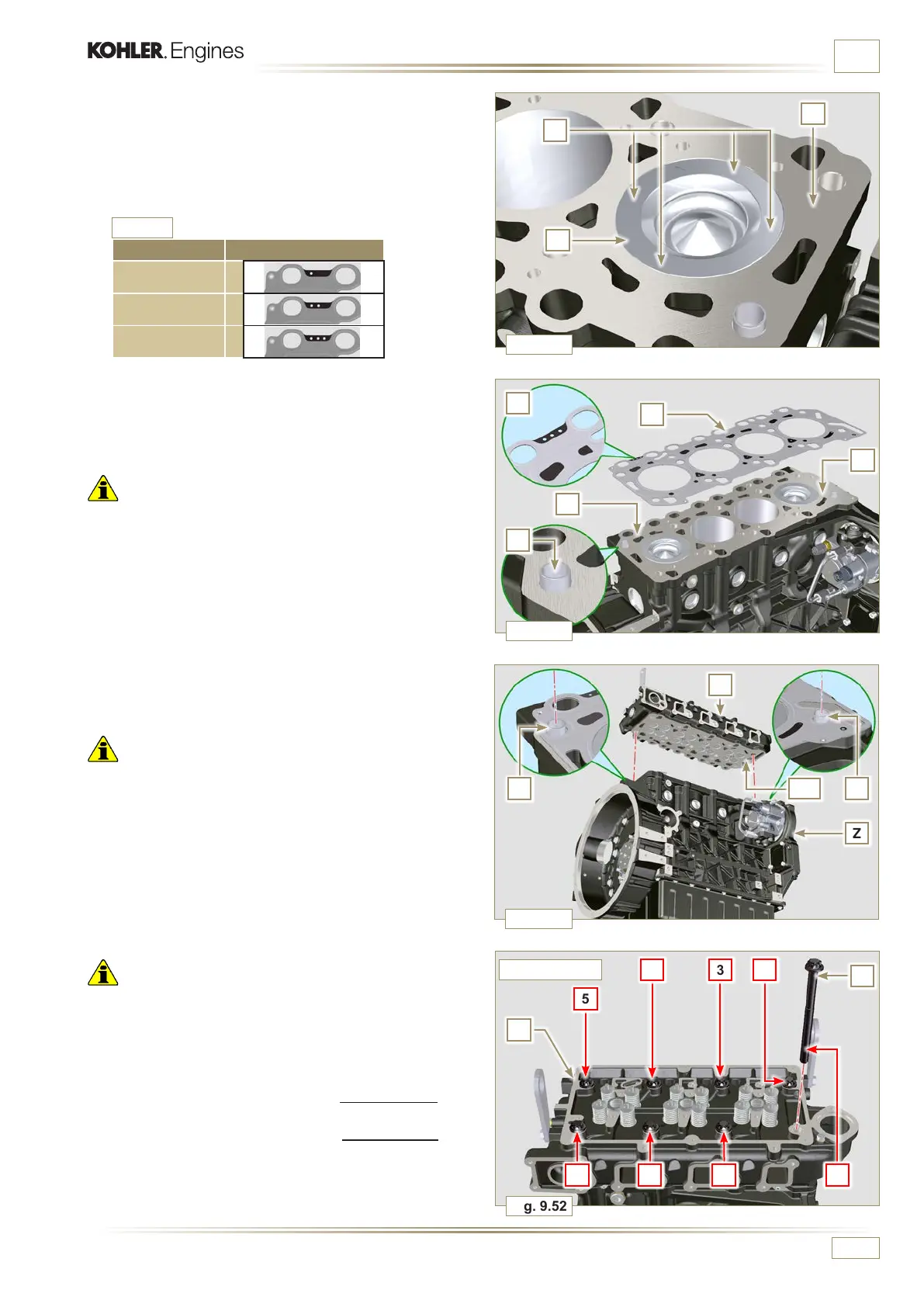

Fig. 9.51

F

W

Z

JJ

Fig. 9.49

R

P

K

Fig. 9.50

K

F

J

U

T

K

ED0053029590

ASSEMBLY INFORMATION

7 - Check that the surface head W is free from impurities.

8 - Position the head F on the crankcase Z with reference to

the centering bushings J.

Important

• The fastening bolts V must be replaced every time they are

assembled.

9 - Secure the head F by tightening the screws V strictly

following the sequence indicated in the Fig. 9.52 or Fig.

9.53 and the tightening torque indicated in the Tab. 9.3.

Important

• Failure to adhere to the bolt fixing procedures may

compromise the functionality of the engine, and also may

cause damage to persons and property.

• Tighten capscrews V observing the cycles, tightening, and

subsequent rotation as indicated in Tab. 9.3.

• For engine KDI 1903 TCR: 8 screws Torx M12 x1,25 (Fig.

9.52).

• For engine KDI 2504 TCR: 10 screws Torx M12x1,25 (Fig.

9.53).

3 CYLINDERS

2 - Position the piston P at the TDC.

3

- Position the tool ST_03 on the crankcase surface of the

head and measure the piston protrusion P from head level

K in 4 diametrically opposed points R.

Repeat the operation for all pistons P and take note of the

highest average value, determining value S (Tab. 9.2).

4 -

Based on the value detected at point 3, select the relevant

gasket T as shown in the Tab. 9.2 (Fig. 9.50 detail U).

5 - Check that the crankcase surface K and the gasket T are

completely free of dirt and grit.

Important

• The head gasket must be replaced for each assembly.

6 - Position the gasket T on the surface K with reference to the

centering bushings J.

S (mm) Hole number

0.030 - 0.126 1

0.127 - 0.250 2

0.251 - 0.375 3

Tab. 9. 2

Loading...

Loading...