190

12

_07

C

A

F

B

D

A

A

A

A

A

B

E

DGA

ED0053029590

INFORMATION ON ADJUSTMENTS

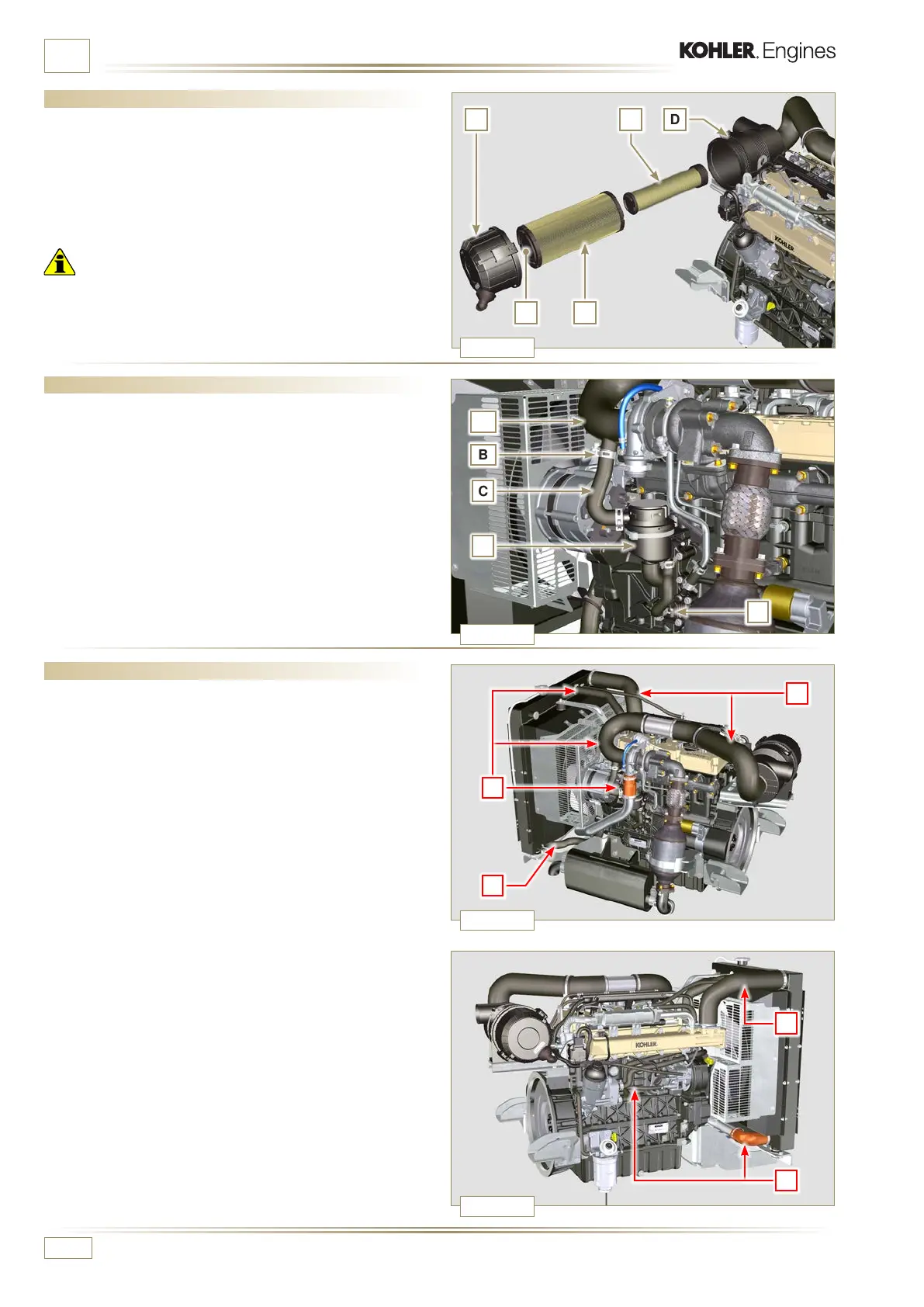

12.2 Air lter check

1 -

All manifolds connected to the turbo must be fully clean

and not damaged.

2 -

Clean the inside components A and D with a damp cloth.

3 -

Do not use compressed air, repeatedly tap the front side

E on a at surface.

Important

• When the cartridge G is dirty, do not clean it but replace

cartridges B and G.

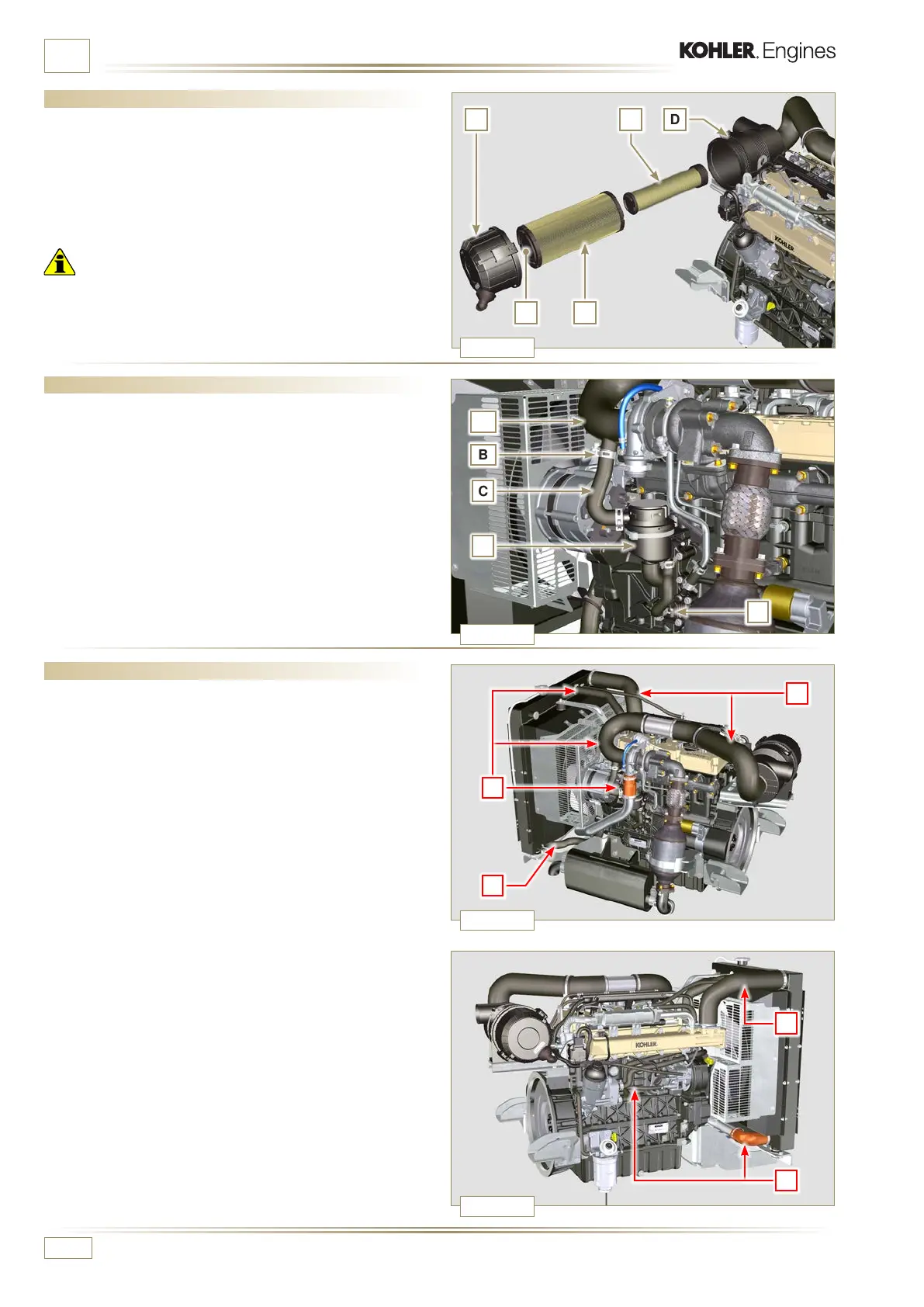

12.3 Oil steam separator check

1

- Loosen clamp B and remove hose C from hose D.

2 - Start the engine at idle speed or without a load and check

if air comes out of the hose D.

NOTE:

If what is described in Point 2 does not occur,

proceed with cleaning or replacing oil separator A

and accurately clean support flange F, all connecting

hoses, and repeat the operation from point 2.

12.4 Rubber hoses and manifolds check

The check is carried out by applying slight deection or

bending along the tube/hose and next to the hose clamps.

C o m p o n e n t s m u s t b e r e p l a c e d i f t h e y h a v e c l e a r s i g n s o f c r a c k s ,

tears, cuts, leaks, or do not retain a certain degree of elasticity.

1 -

Check the condition of all rubber hoses A.

2 - Check whether there are any leakages of air, coolant, oil or

fuel next to their connections

Fig. 12.2

Fig. 12.3

Fig. 12.4

Fig. 12.5

Loading...

Loading...