191

12

_07

A

A

A

A

A

A

B

C

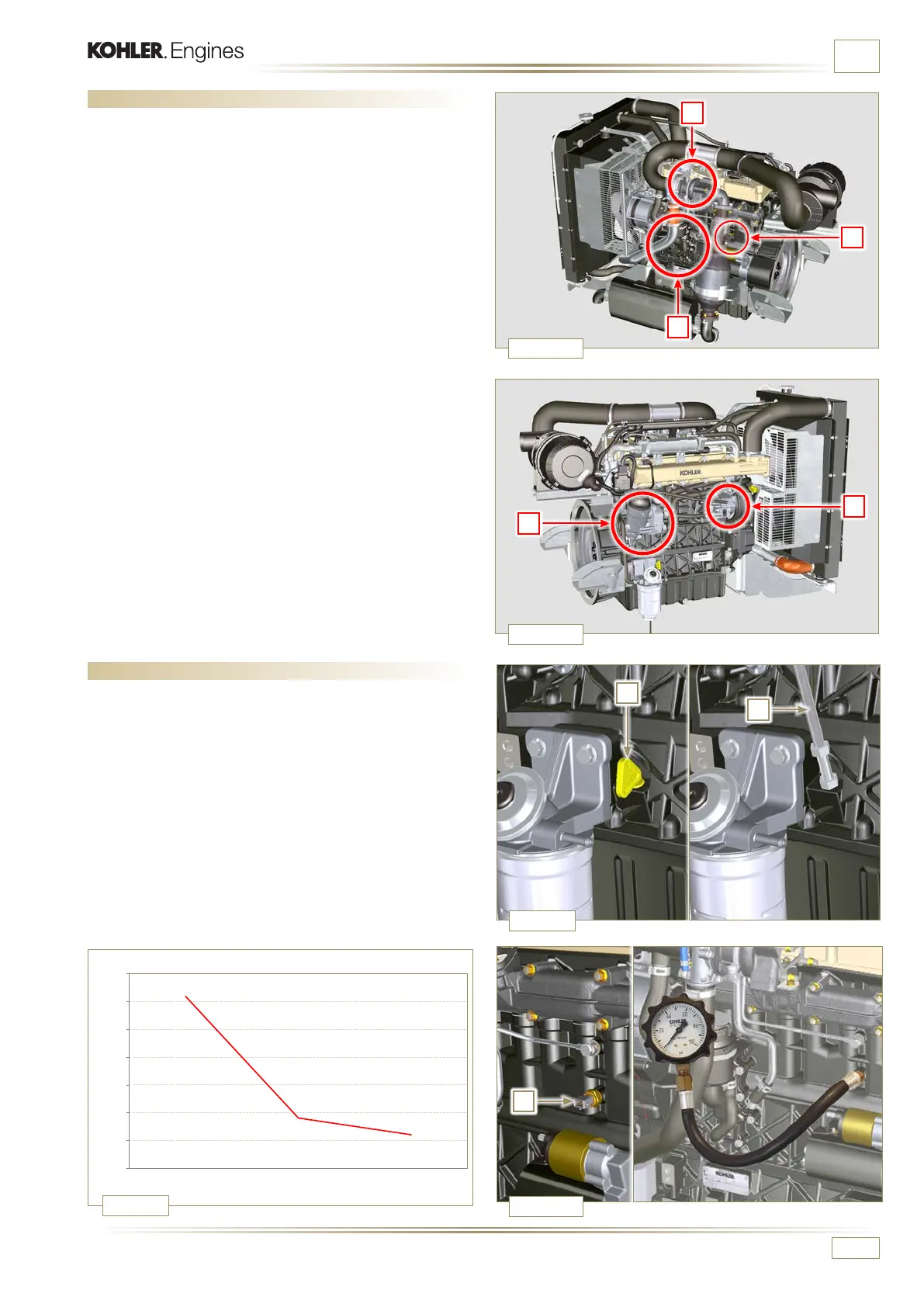

Fig. 12.6

Fig. 12.7

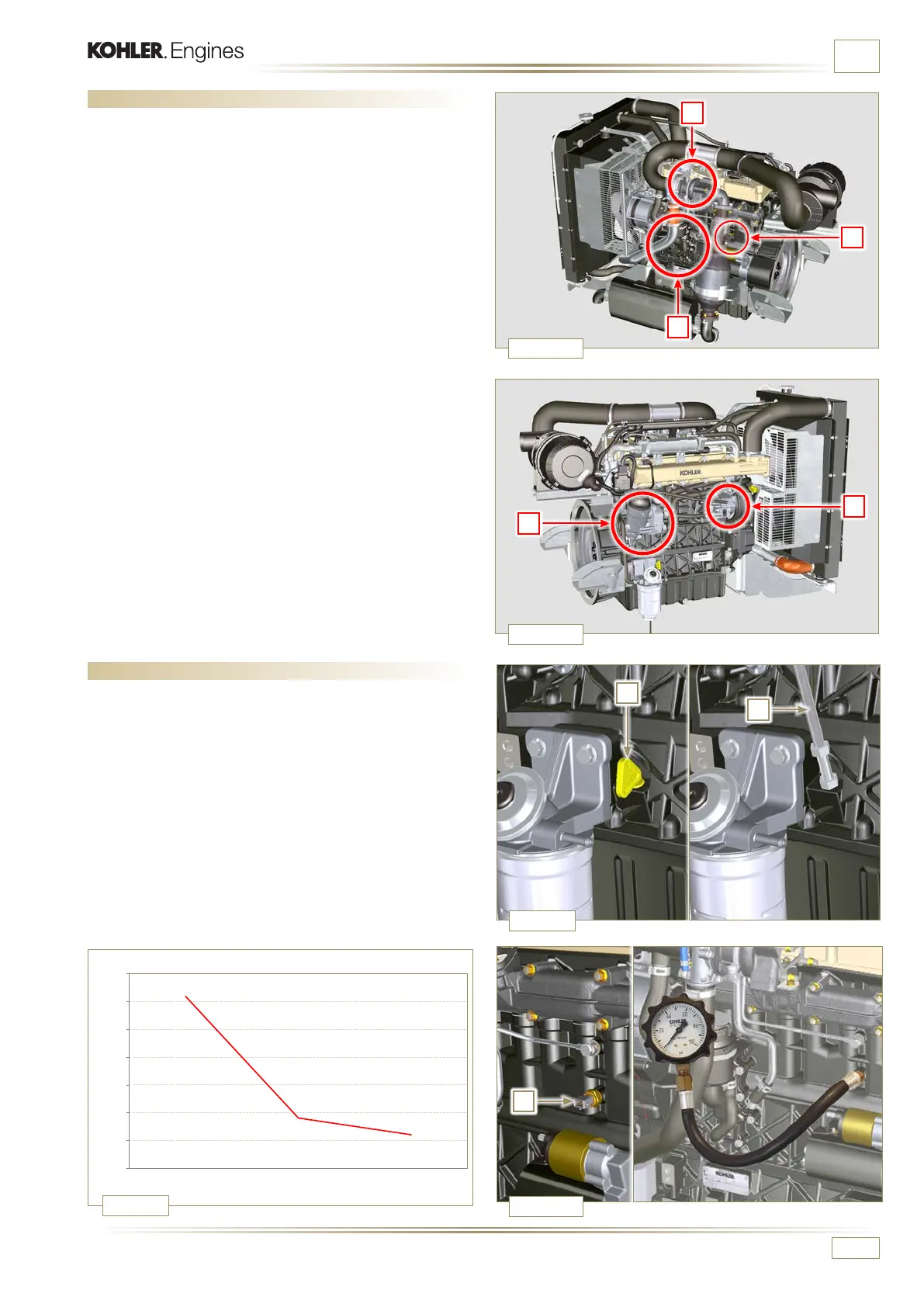

Fig. 12.8

Fig. 12.10

Fig. 12.9

ED0053029590

INFORMATION ON ADJUSTMENTS

12.5 Oil leak check

Check that there are no leakages next to area A.

1 -

Start the engine at idle speed or without a load and check

whether there are any leakages next to area A.

2 - It is anyhow necessary to also check the seals of all main

components and their surface contact, such as:

- crankcase and gasket (side 1a PTO)

- oil sump and exhaust caps

- cylinder head and its assembled components

- rocker arm cover

- Timing system carter and gasket (side 2

a

PTO)

- oil dipstick housing or rod support tube.

NOTE:

Perform the checks described in Points 1 and 2

periodically and during maintenance procedures.

It is also necessary to check for leakages on the

components that are not listed.

I f n e c e s s a r y, d i s a s s e m b l e t h e c o m p o n e n t s t h a t h a v e a l e a k a g e

and investigate the possible cause.

The components must be replaced otherwise they do not

guarantee their sealing.

12.6 Oil pressure check

1

- Replace the oil dipstick A with a thermocouple B.

2 - Unscrew and remove the oil pressure switch C and screw

on a 10 bar pressure gauge in its seat (Fig. 12.10).

3 - Start the engine at idle speed and without a load, check

the oil pressure value according to the oil temperature

(Fig. 12.9).

NOTE: The graph in Fig. 12.9 illustrates the pressure line

with speed of 1000 Rpm.

4 - If the pressure values are below the values indicated in

Fig. 12.9, check to identify the cause of the problem.

Loading...

Loading...