6

85

_07

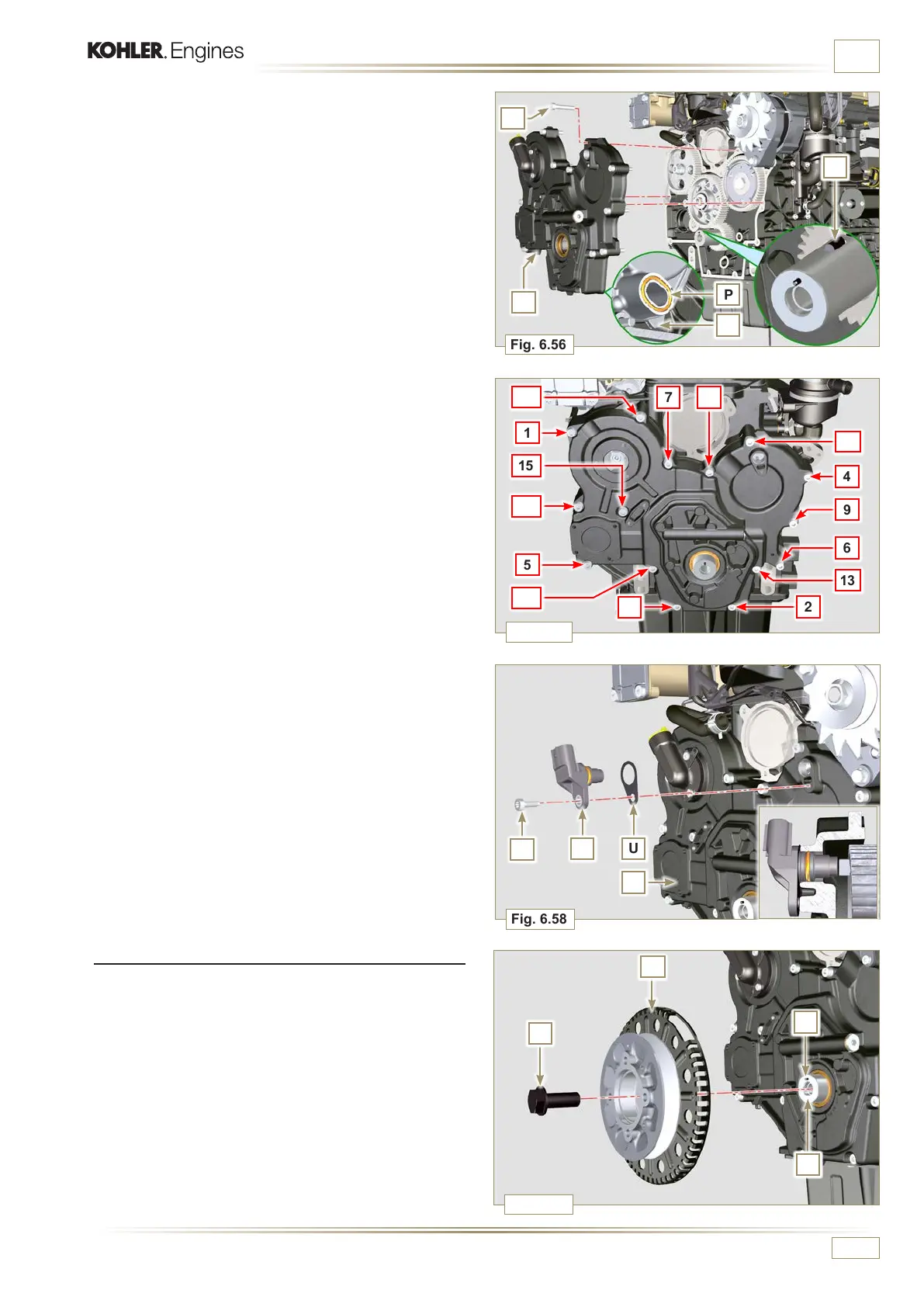

Fig. 6.58

S U

T

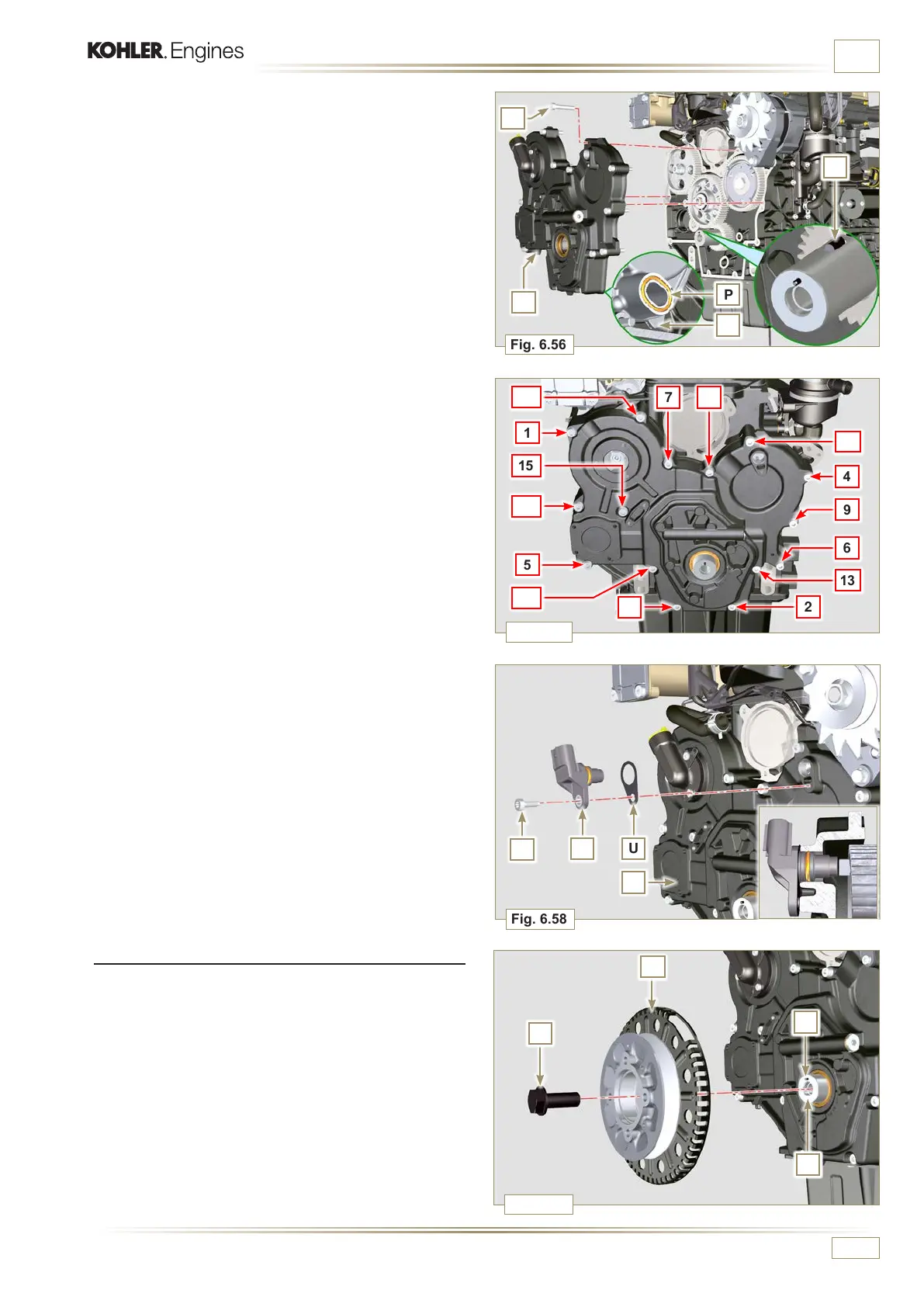

Fig. 6.56

P

Q

C

R

M

Fig. 6.59

Y

W

Z

C

1

15

10

5

14

3

12

7 8

2

13

6

9

4

11

Fig. 6.57

A

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

9 - Assemble sensor S by means of capscrew T on carter C

inserting gasket U (tightening torque at 10 Nm - ST_06).

5 - Lubricate and insert the gasket P in the seat of the oil pump Q.

6 - Tighten the tool ST_10 on the crankshaft.

7 - Position the crankcase C on the base, using the reference

pins N, inserting the oil pump Q on the crankshaft.

6.7.7 Crankshaft and phonic wheel pulley assembly

1 - Leave the tool ST_34 mounted (Fig. 6.44).

2 - Check that the pin A is mounted properly on the crankshaft Z.

3 - Position the pulley unit W on the crankshaft Z respecting

the reference with the pin A.

4 - Apply Molyslip grease on the screw thread Y.

5 - Clamp the pulley unit W with the screw Y (tightening torque

at 360 Nm).

6 -

Remove the special tool ST_34 (Fig. 6.44).

8 -

Fit the timing system crankcase C with the screws R

observing the indicated clamping sequence (tightening

torque at 25 Nm).

Loading...

Loading...