6

86

_07

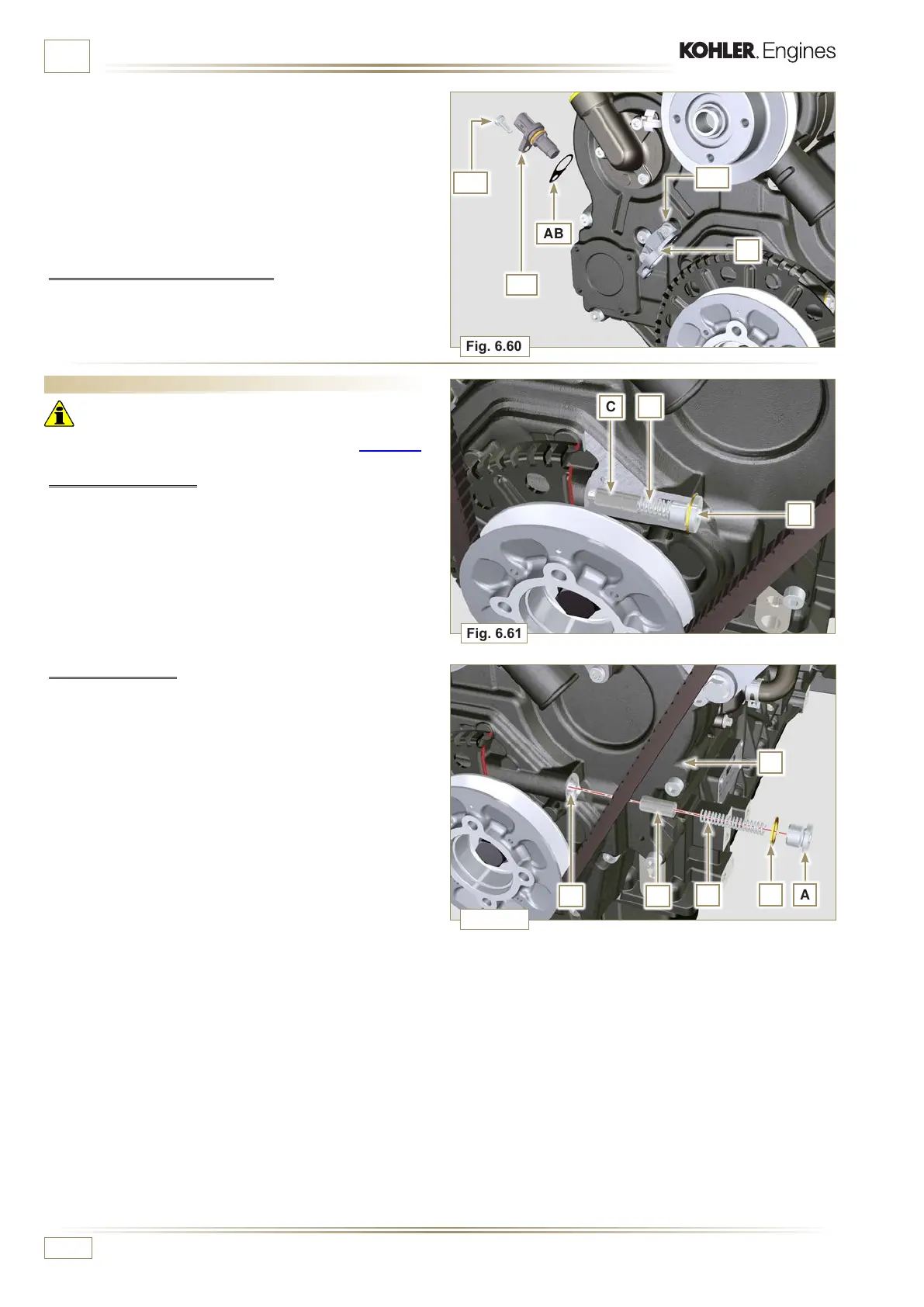

Fig. 6.60

Z

AA

AB

AD

AC

W

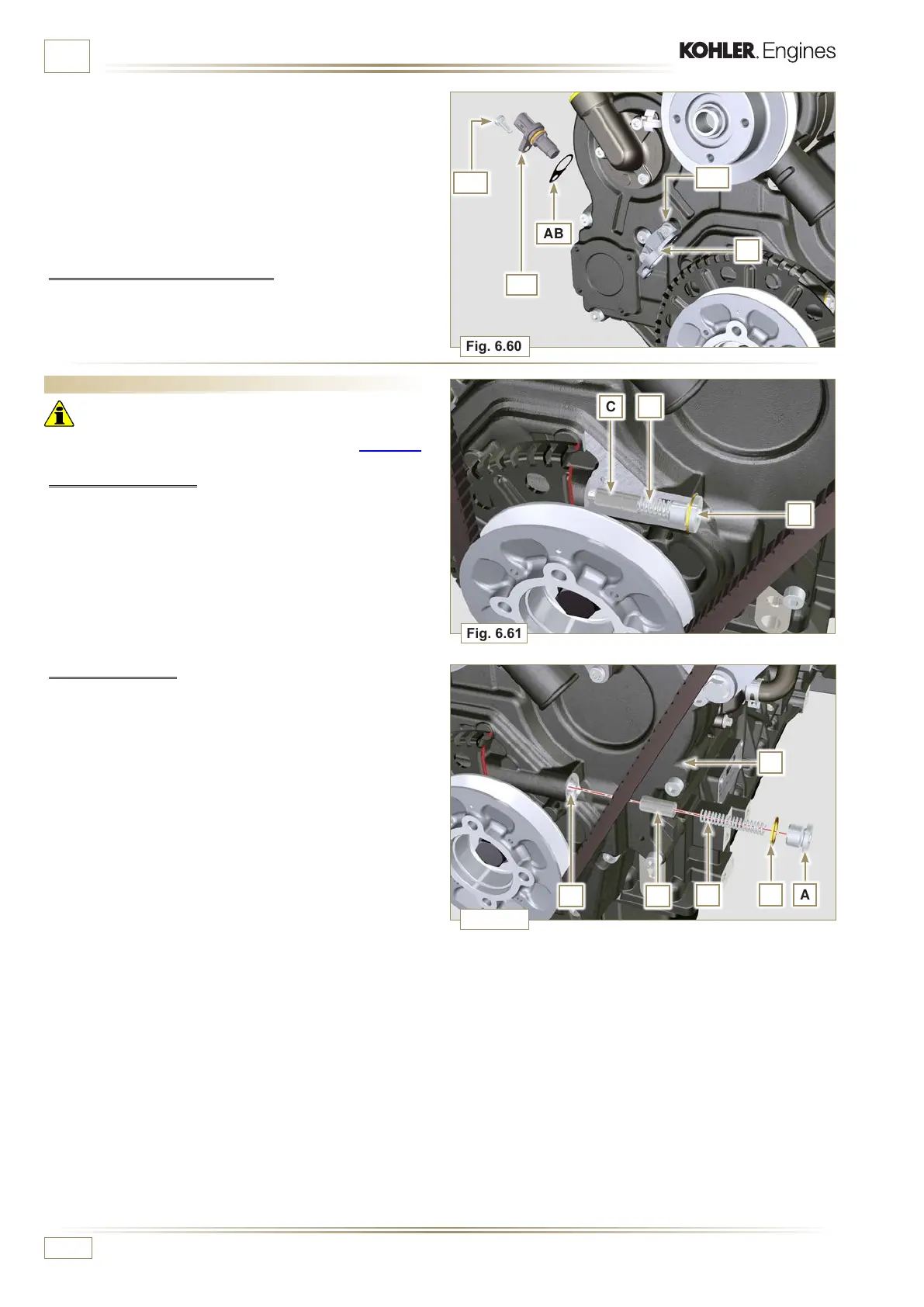

C B

A

Fig. 6.61

CE

B

AF

D

Fig. 6.62

ED0053029590

INFORMATION FOR REPLACING THE FUNCTIONAL UNITS

7 - Mount the bracket Z with the screws AA (tightening torque

at 10 Nm).

8 -

Perform the operations described in Par. 9.12.

9 -

Insert the shim AB on the sensor AC.

10 -

Clamp the sensor AC on the bracket Z with the screw AD

(tightening torque at 10 Nm).

6.7.8 Coolant pump assembly

11 - Perform the operations described in Par 6.5.2.

6.8 Oil pressure valve replacement

Important

• Before proceeding with operation, carefully read Par. 3.3.2.

6.8.1 Disassembly

1 - Undo cap A.

2 - Remove spring B, check its condition and replace it if

broken.

3 - Remove the valve piston C using a magnet.

6.8.2 Assembly

1 - Lubricate the piston C and fully insert it in the seat E.

2 - Insert the spring B in the piston.

NOTE: Always replace the gasket F after each assembly.

3 - Mount the gasket F on cap A.

4 - Clamp the cap A on the crankcase D (tightening torque at

50 Nm).

Loading...

Loading...