.

MAINTENANCE

SERVICE PROCEDURE

PROCEDURE FOR BLEEDING AIR IN HYDRAULIC SYSTEM

After replacing or cleaning the hydraulic oil, filter element, or strainer, bleed the air from the hydraulic circuit.

See "STARTING ENGINE (PAGE 3-84)".

Since the engine must be started and the blade must be operated, see OPERATION.

1.

Bleeding air from pump

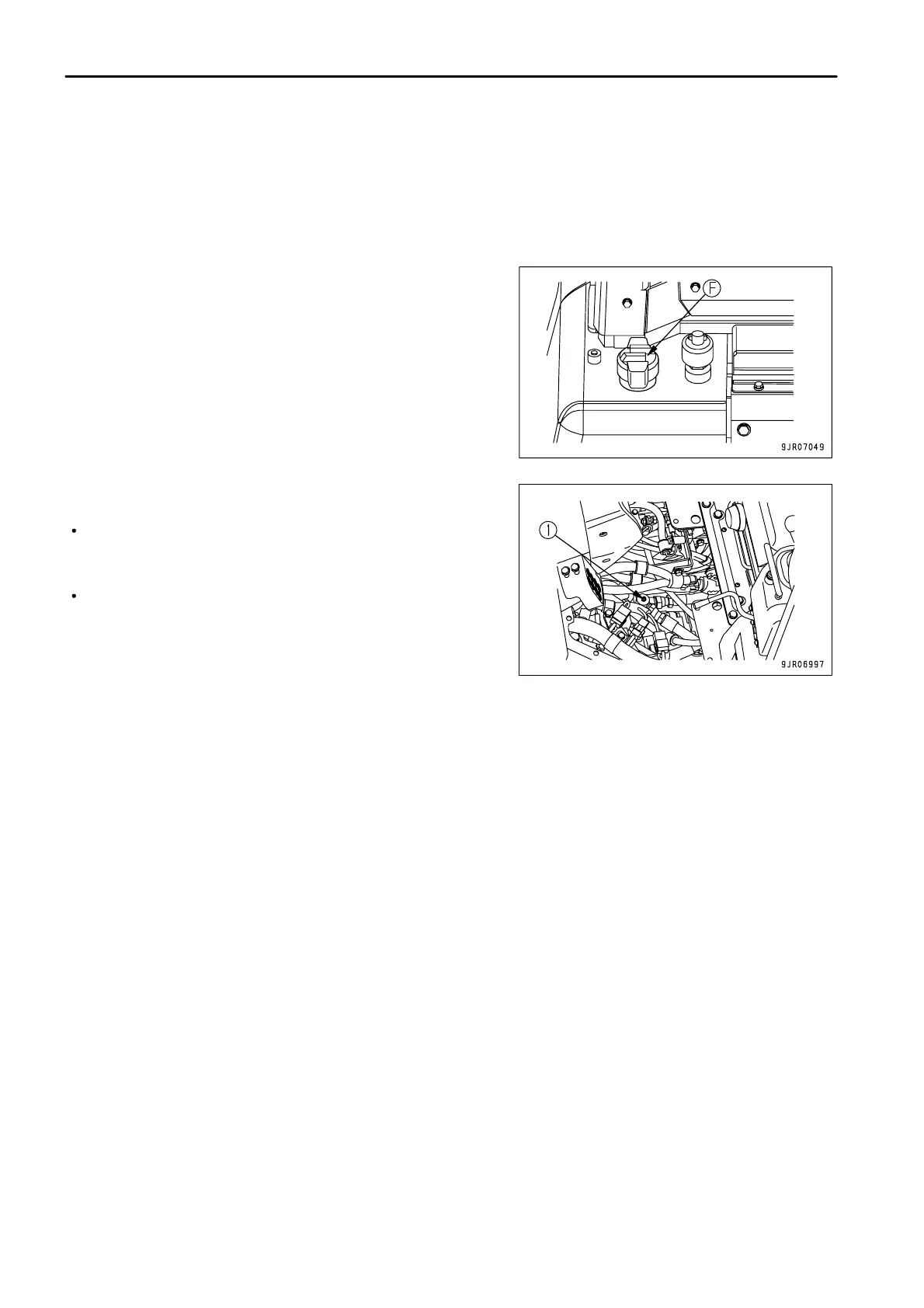

1) Remove the cap of oil filler (F) at the top of the hydraulic

tank.

2)

Remove the floor mat and floor plate.

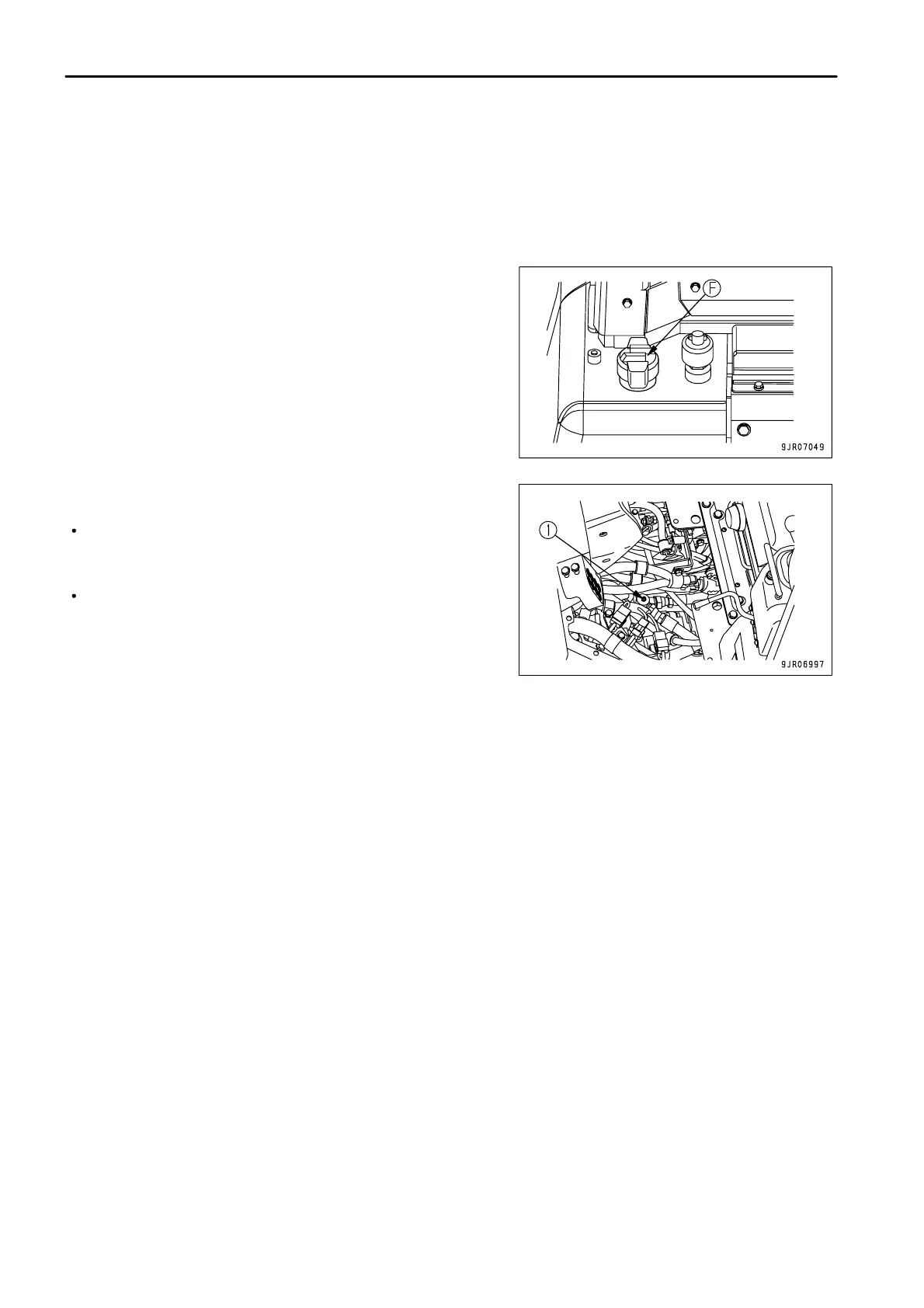

3) Loosen air bleeder (1) installed to the drain port and check

that oil oozes out.

4)

After completion of the air bleeding operation, tighten the

air bleed plug.

Tightening torque: 11.8 - 14.7 Nm {1.2 - 1.5 kgm (8.7 - 10.8

lbft)}

5) Close the hydraulic tank cap.

NOTICE

If the inside of the pump case is not filled with hydraulic oil and the

pump is operated, there is danger that it will generate abnormal heat and

this will cause premature damage to the pump.

Always bleed the air.

2.

Starting engine

Start the engine and run for 10 minutes at low idle. For details, see "STARTING ENGINE (PAGE 3-84)".

After running for 10 minutes at low idle, move to the next operation.

3. Bleeding air from cylinders

1)

Run the engine at low idle, and extend and retract each cylinder 4 to 5 times, taking care that a cylinder is

not moved to the end of its stroke. (Stop the cylinder approx. 100 mm (3.9 in) short of its stroke end)

2)

Next, operate each cylinder 3 to 4 times to the end of its stroke.

3)

Next, run the engine at high idling and operate each cylinder 4 to 5 times to the end of its stroke to bleed the

air completely.

NOTICE

If the engine is run at high speed immediately after startup or a cylinder is pushed up to its stroke end, air taken inside the cylinder

may cause damage to the piston packing.

4. Operation

1)

After completing the bleeding of the air, stop the engine, and wait for at least 5 minutes before starting

operations. This will release the bubbles in the oil inside the tank.

2) Check that there is no oil leakage, and wipe off any oil that has been spilled.

4 - 46

Loading...

Loading...