Service procedure Maintenance

5-40 WA70-5 – VEAM320100

Lubrication of work unit

Lubricating points of the work unit

DANGER

● If you perform maintenance operations at a machine

which is not properly parked and secured, severe acci-

dents may occur!

● Park the machine on firm, level ground and secure it

before starting the maintenance operations.

1. Park and secure machine for the maintenance operations as

described in chapter "5.1. Maintenance guide" on page 5-2.

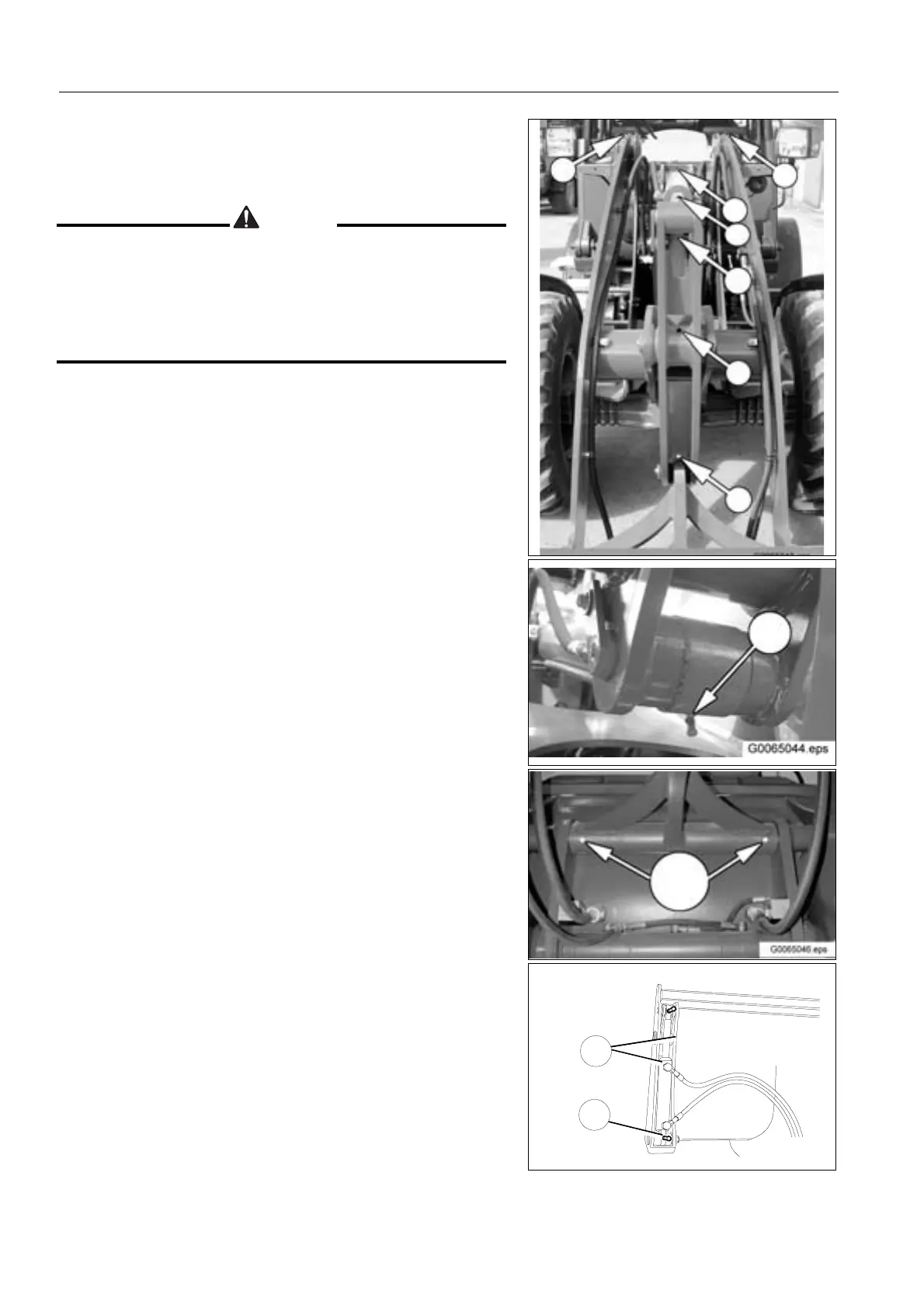

2. Clean the grease nipples which are indicated by the arrows.

3. Use a grease gun to press sufficient grease into the grease

nipples.

4. Remove the old grease which is extruding at the bearings.

NOTE

If you operate in humid conditions or in a salty environment,

you must reduce the lubricating intervals.

3

3

4

4

2

2

1

1

5

75_263

6

6

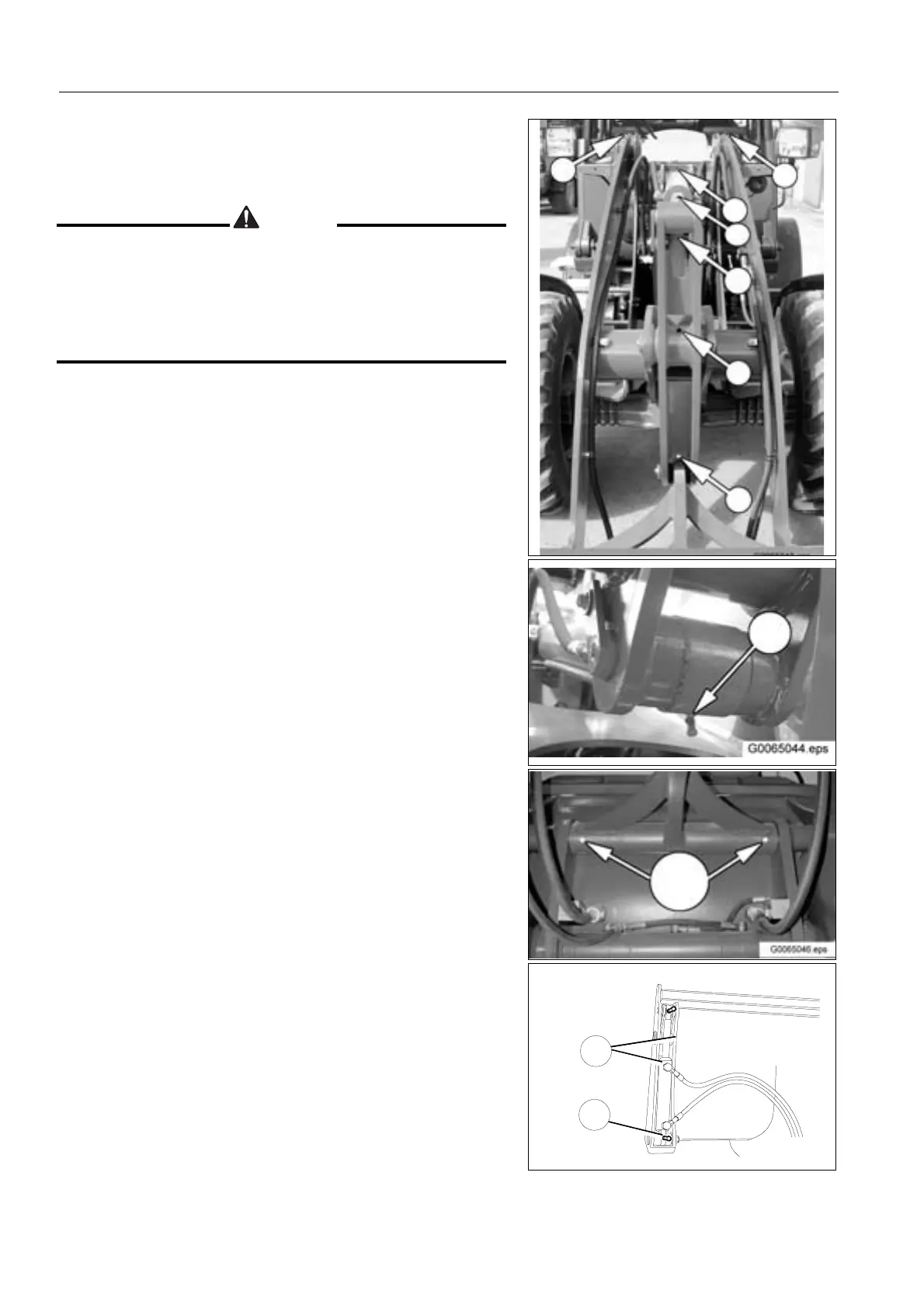

(1) Lifting cylinder right and left side (2 locations)

(2) Rocker arm (2 locations)

(3) Boom (2 locations)

(4) Tipping cylinder (2 locations)

(5) Quick-change unit (2 locations)

(6) Clamshell bucket (6 locations)

Loading...

Loading...