Do you have a question about the Kongsberg Seatex RADius 1000 and is the answer not in the manual?

The RADius 1000 system is a high-precision reference and tracking system designed for short-range and direction monitoring, primarily used in operations where increased safety is crucial, such as assisting automatic dynamic positioning (DP) of a vessel. It is designed to operate effectively close to structures and other vessels, minimizing the risk of tracking false radar echoes through the use of identifiable transponders. The system's performance improves as it moves closer to the transponders, offering complementary characteristics to DGPS systems, especially in scenarios where DGPS availability might be degraded due to limited sky view (e.g., when operating near large structures).

The RADius system utilizes low-power Frequency Modulated Continuous Wave (FM-CW) radar principles to measure the distance and bearing to one or more transponders. The system consists of two main physically separated parts: an Interrogator Unit and a Controller Unit/Processing Unit (CU). Additionally, it includes one or more transponders, a Video Display Unit (VDU), power cables, signal and power cables between the Processing Unit and the Interrogator Unit, and documentation.

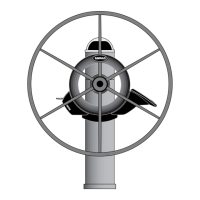

The Interrogator Unit, mounted on the DP vessel, is the actual radar module that measures distance and bearing to the transponders. It is a sealed unit comprising a transmitter, a receiver, and pre-processing modules. Power is supplied from the power/connection shelf in the CU. The Interrogator communicates with the Processing Unit via an Ethernet link.

Transponders, acting as radar reflectors, are mounted on the remote object or vessel. Each transponder receives the signal from the Interrogator, mixes the input signal with its own unique identity frequency (sub-carrier), and reflects the signal back. This unique ID allows the system to separate different transponders and track up to five simultaneously, enhancing system integrity and robustness.

The Controller Unit, typically installed on the bridge or in an instrument room, includes a Processing Unit (3U), a Power/connection shelf (2U), and a Keyboard/mouse (1U). The Processing Unit, designed for standard 19-inch racks, contains a hard disk, a 3.5-inch floppy disk for software installation and upgrade, serial and analog I/O boards, a computer main board, and a 110/230V AC power supply. Its front panel features an ON/OFF switch, four status indicator lights, and an RS-232 serial port (COM1) for service. The rear panel provides various communication interface ports for external systems, including VGA for display, Ethernet for Interrogator and external equipment interfaces, RS-422 for MRU, parallel port, and multiple RS-232/422 configurable serial ports for user output. The Power/connection shelf provides power and network interfaces to the Interrogators, housing an Ethernet switch, an ON/OFF switch with an integrated fuse, and 110/230V AC power supplies for both Interrogators and the Ethernet switch. A 1U keyboard with an integrated trackball serves as the primary input device.

| Brand | Kongsberg |

|---|---|

| Model | Seatex RADius 1000 |

| Category | Marine Equipment |

| Language | English |