Do you have a question about the Kongsberg Simrad EK80 and is the answer not in the manual?

Identifies the intended readers of the manual, assuming technical background.

Outlines the importance of following instructions for optimal performance and system setup.

Information on downloading end-user manuals and other relevant documentation from the website.

Lists registered trademarks, including Windows and Simrad products.

Encourages user feedback for continuous improvement of the EK80 and its documentation.

Highlights critical information and precautions before operating the EK80 system.

Provides an overview of the EK80's capabilities and applications.

Describes the key components of the EK80 system, such as display, processor, and transceiver.

Details the standard and optional items included with the EK80 system delivery.

Outlines critical safety precautions to be followed during installation and maintenance of the EK80.

Details necessary conditions and specifications for a successful EK80 installation.

Discusses data security considerations when connecting the EK80 to a local area network.

Provides contact details for technical support, offices, and dealers.

Outlines the sequential tasks required for a complete EK80 installation.

Explains the importance and availability of design and installation drawings.

Lists necessary tools and materials for the EK80 installation process.

Specifies the required skills and certifications for installation personnel.

Provides guidelines and considerations for optimal transducer placement on the hull.

Discusses sources of acoustic noise and their impact on EK80 performance.

Explains the system for defining relative physical locations of sensors and transducers.

Guides the installation of the WBT using its built-in mounting brackets.

Details the process of installing the WBT into a standard 19-inch rack.

Covers the installation procedure for the WBT power supply unit.

Outlines the steps for installing the EK80 display unit.

Provides guidance for installing a customer-provided computer as the EK80 Processor Unit.

Details the installation of the specific Enix Processor Unit.

Explains the installation of the Ethernet switch required for multi-transceiver systems.

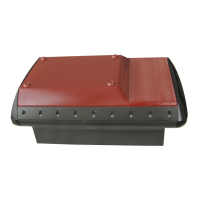

Describes the process of mounting the WBT Cabinet, including its shock absorbers.

Guides the installation of drawers within the WBT Cabinet for holding transceivers.

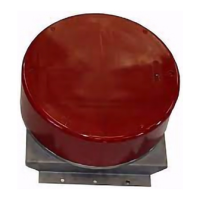

Covers the procedure for installing the EK80 transducers, including hull penetration.

Provides essential preliminary information and warnings regarding EK80 cabling.

Offers methods to minimize electrical noise interference in the EK80 system.

Presents diagrams illustrating various EK80 system configurations and their cabling.

Provides a comprehensive list of EK80 cables with their types and requirements.

Outlines the procedures for installing all EK80 system cables correctly.

Details how to connect EK80 components to various external hardware.

Explains how to configure the EK80 for synchronized operation with other systems.

Provides detailed drawings and specifications for various EK80 cables.

Covers general requirements for cable installation, protection, and grounding.

Explains the KVM extension system for remote control of the EK80.

Describes the Moxa CP114EL-I adapter for serial communication.

Explains the function and specifications of the Øverland UPC-3005 serial splitter.

Details the Øverland UPC-5000P serial splitter for distributing serial data.

Explains the concept of synchronization to avoid interference between hydroacoustic systems.

Describes modes like Stand-alone, Master, and Slave for EK80 synchronization.

Details synchronization sequences using RS-232, CTS, and RTS signals.

Explains synchronization using RS-232 CTS/RTS signals for controlling transmissions.

Describes using the WBT Auxiliary socket for more stable transmit synchronization.

Guides setting up EK80 synchronization using a serial port for Master/Slave operation.

Details how to synchronize the EK80 using the WBT's Auxiliary port for stable operation.

Details the AC power cable specifications and connection using an IEC C13 socket.

Explains the requirements and connection for the ground cable.

Describes the RS-232 serial connection using three wires for NMEA datagrams.

Details the RS-232 serial connection using five wires for NMEA datagrams.

Explains the RS-422 serial connection using five wires for high-speed data transmission.

Describes using RS-232 control signals for external synchronization triggers.

Details RS-485 serial connections for long distances in noisy environments.

Provides specifications for the Moxa CP114EL-I serial adapter.

Details the specifications for high-speed Ethernet cables used for EK80 connections.

Specifies the cable requirements for powering the WBT from a battery.

Explains the K-Sync interface for RS-232 synchronization using CTS/RTS signals.

Details the auxiliary connector pinout for synchronization purposes.

Describes connecting single beam low power transducers to an Amphenol socket.

Explains the connection of split beam transducers to an Amphenol socket.

Details using split beam transducers for single beam applications.

Describes Burton connectors used on split beam transducers for deep water operation.

Discusses serial line standards (RS-232, RS-422, RS-485) for peripheral communication.

Outlines requirements for supporting and protecting cables using trays or conduits.

Addresses measures to mitigate radio frequency interference affecting cables.

Details methods for protecting cables from physical damage using conduits or casings.

Explains the correct procedures for electrically grounding system cables.

Describes how cable connections and terminations should be made according to diagrams.

Covers the requirements for identifying cables with specific codes and markings.

Explains the use and procedures for cable glands in sealing and securing cables.

Details tasks for ensuring high-quality EK80 measurements through alignment and calibration.

Outlines procedures for measuring sensor positions and orientations.

Specifies accuracy requirements for dimensional surveys in ADCP operations.

Notes that no specific requirements are defined for echo sounding dimensional surveys.

Explains the system for defining relative physical locations of sensors and transducers.

Provides a sequential overview of tasks required to get the EK80 operational.

Covers visual inspections and checks to ensure the EK80 is ready for operation.

Details the initial power-on and basic setup procedures for the EK80.

Guides the installation and troubleshooting of NTP for time synchronization.

Explains how to set menu language, measurement units, and data recording parameters.

Covers the process of connecting and configuring external sensors and systems.

Outlines various tests to verify the EK80's functionality and performance.

Provides the correct procedure for safely shutting down the EK80 system.

A page for recording comments and signing off on the installation.

Provides an overview of the technical specifications section.

Details the datagram formats and protocols used for EK80 interfacing.

Summarizes the power supply requirements for EK80 components.

Lists the physical dimensions and weights of EK80 system components.

Details the temperature and humidity requirements for EK80 operation.

Specifies the minimum distance units must be kept from a compass.

Lists the minimum technical specifications for the computer used with the EK80.

Outlines the minimum technical requirements for the EK80 display.

Explains the purpose and availability of installation drawings.

Provides specific outline dimensions for the WBT.

Lists the specific dimensions for the Processor Unit.

Provides outline dimensions for the WBT Cabinet.

Details the assembly and wiring of transducer connectors.

Outlines methods for transporting sensitive equipment approved for delicate items.

Gives advice on safely lifting heavy units and boxes.

Describes visual inspection procedures upon receiving equipment.

Details requirements for storing equipment before installation.

Provides guidance on safely unpacking electronic, mechanical, and standard units.

Outlines storage requirements after the equipment has been unpacked.

| Brand | Kongsberg |

|---|---|

| Model | Simrad EK80 |

| Category | Marine Equipment |

| Language | English |