Water system

The water must be lead to the high pressure cleaner under pressure (2 – 8 bar

ad-mission pressure). A oat valve regulates the water inlet. Then, the water is

sucked by the high pressure pump from the water tank and supplied to the lance

under the set pressure. The high pressure jet is formed by the nozzle at the end of

the lance.

Description

6

5

Lance with spray gun

The machine can only be operated when the safety trigger is squeezed.

When the lever is squeezed, the spray gun opens. The liquid is then pumped to

the nozzle. The spray pressure increases and quickly reaches the selected oper-

ating pressure.

When the trigger is released, the trigger gun closes and any further spraying of

liquid from the lance is stopped and the manometer must show 0 bar.

The increase in pressure when the trigger gun is closed causes the unloader

valve-safety valve to open. The pump remains switched on and continues to pump

liquid through the pump at reduced pressure. When the spray gun is opened, the

unloader valve - safety valve closes and the pump ressumes spraying from the

lance with the selected operating pressure.

The spray gun is a safety device. Repairs should only be per-

formed by qualied persons. Should replacement parts be re-

quired, use only components authorized by the manufacturer.

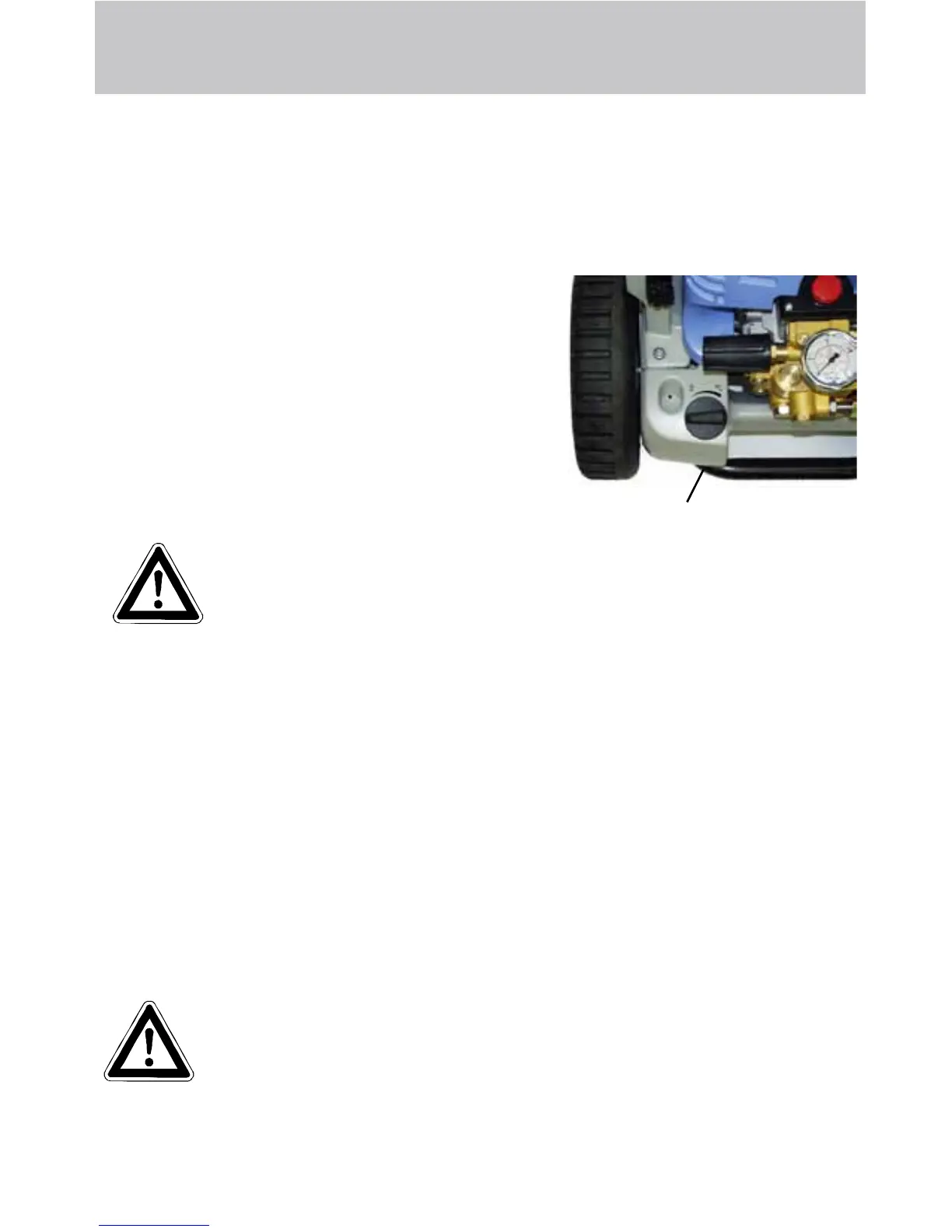

Detergent and caring system

The high pressure pump can also suck a de-

tergent/caring agent and mix it with the high

pressure jet. The additive is sucked through the

pump and brought in with the set pressure.

Insert the detergent hose into the detergent con-

tainer and open the detergent valve (6).

The detergent discharges with the water at the

high pressure nozzle.

Open the dosing valve, if the chemistry sieve is placed in a

liquid. Sucked air leads to destruction of the pump seals!!!

The rules concerning the environment, refuse and ground water

protection must be complied with!

Loading...

Loading...