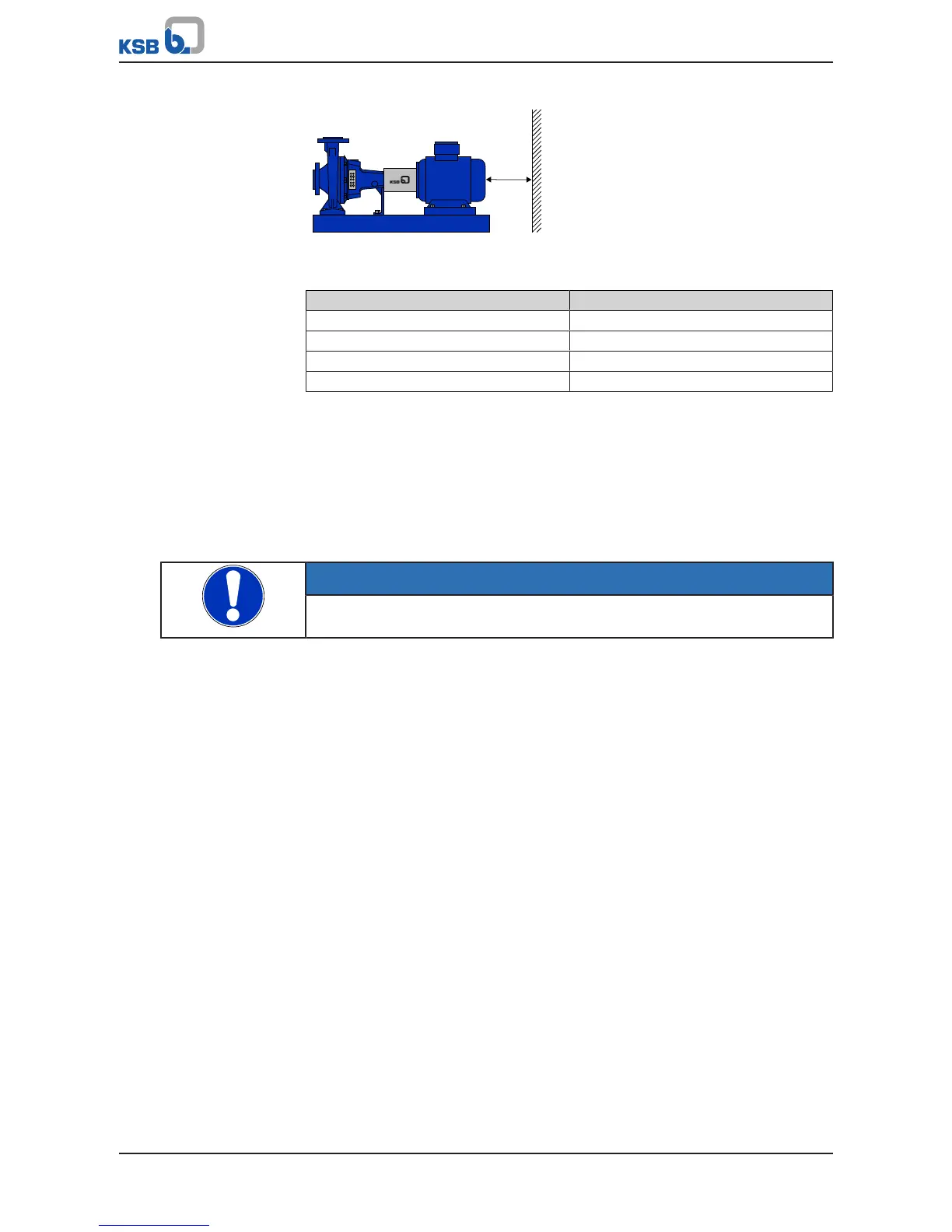

Fig.2: Minimum distanceX

Table8: Minimum distanceX to neighbouring assemblies

Motors with shaft centreline height [mm] Minimum distanceX [mm]

71 - 100 30

112 - 132 40

160 - 180 50

200 - 225 60

5.2 Installing the motor

Checks prior to installation work

▪ Repair any damage to the paintwork. (ðSection7.2.2.1,Page28)

▪ Remove any anti-corrosives applied to exposed metal parts that are required to

ensure proper assembly or installation.

Alignment and fastening

NOTE

Maintain the vibration levels to ISO 10816-1 during operation.

Observe the following when aligning and fastening:

▪ Ensure that the motor feet are resting evenly on the support surface.

▪ Ensure that feet and flanges are mounted as specified in the manual.

▪ Avoid rigid couplings.

▪ Ensure precise alignment for direct coupling.

▪ Ensure that mounting surfaces are free from contamination.

▪ Avoid resonances caused by the structure at the rotational frequency and double

mains frequency.

▪ Unusual noise that may occur when rotating the rotor by hand.

Compensation of radial

misalignment at the

coupling and horizontal

adjustment

The following measures are required to compensate radial misalignment at the

coupling and horizontally adjust the motor in relation to the driven machine (e.g. the

pump):

▪ Vertical positioning

To avoid distortion (warping) of the driven machine and the motor, place thin

metal sheets under the motor feet.

The number of shims should be restricted to a minimum, in other words, they

should only be stacked if this is unavoidable.

▪ Horizontal positioning

For horizontal positioning, laterally shift the motor on the foundation while

maintaining axial alignment (to prevent angular misalignment).

Ensure a uniform circumferential axial clearance at the coupling when

positioning.

▪ Smooth running characteristics

A stable, vibration-free foundation to DIN4024, exact alignment of the coupling

and a well-balanced output element (coupling, pulley, fan, etc.) are prerequisites

Loading...

Loading...