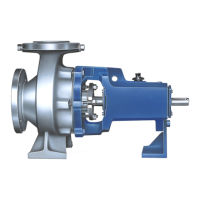

Why KSB Megabloc Water Pump does not pump or pumped flow is insufficient?

- BBrittany GlassJul 27, 2025

If your KSB Water Pump isn't pumping effectively, it might be due to several reasons. Ensure the pump is correctly primed. The installation might need adjustments to address suction conditions. Check for excessive suction slope or air pockets in the suction piping. Air leaks in the suction piping could also be the culprit. Verify that the suction valve is fully open and not obstructed. A foot valve that's too small or clogged can also restrict flow. Make sure the suction piping is adequately immersed. Incorrect rotation direction can prevent proper pumping. Confirm that the total head doesn't exceed the specified value. Foreign objects on the impeller or excessive wear of internal parts can also cause issues.