Section 1: Assembly & Set-up

Table of Contents

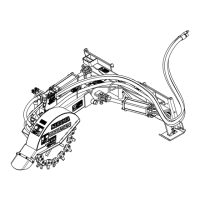

11/13/19AP-SSG2524 Stump Grinder 328-215MK

10

Section 1: Assembly & Set-up

Skid Steer Requirements

The Stump Grinder is designed to attach to a universal

quick attach mounting system. Consult the skid steer

Operator’s Manual for operating capacity, lifting capacity,

and operating specifications. They will vary from unit to

unit. Do not exceed the rated capacities and

specifications of the skid steer.

WARNING

!

To avoid serious injury or death:

Lightweight power machines may need weight added to the

rear to maintain steering control and prevent forward tipping

or side tipping caused by a heavy front load. Consult your

power machine Operator’s Manual to determine proper

weight requirements and maximum weight limitations.

Torque Requirements

Refer to “Torque Values Chart” on page 37 to determine

correct torque values when tightening hardware.

Before You Start

Make sure that the intended skid steer conforms to the

requirements provided on this page. Also, read and

understand this Operator’s Manual for your Stump

Grinder. An understanding of how it works will aid in its

assembly and set-up.

The Stump Grinder is shipped fully assembled except for

the optional quick disconnect hose couplers and wire

harness. See “Section 4: Options” on page 20 for

detailed descriptions of options.

Go through the Set-up Checklist before preparing the

Stump Grinder for field use. To speed up your set-up task

and make the job safer, have all needed parts and

equipment readily at hand.

Set-up Checklist

Check Reference

Make sure all major components and

loose parts are shipped with the

attachment.

Assembly

& Set-up

Double check to make sure all parts,

fasteners, and pins are installed in the

correct location. Refer to the Parts

Manual if unsure.

NOTE: All assembled hardware from the

factory has been installed in the correct

location. Remember location of a part or

fastener if removed. Keep parts

separated.

Operator’s

Manual

328-215MK

Parts

Manual

328-215PK

Make sure working parts move freely,

bolts are tight & cotter pins are spread.

Operator’s

Manual

Make sure all grease fittings are in place

and lubricated.

Page 33

Make sure all safety labels are correctly

located and legible. Replace if damaged.

Page 6

Customer Supplied Quick Couplers

Refer to Figure 1-1 on page 11:

4. Thread hydraulic hoses (#1, #2, & #12) through hose

loops (#5, #6, #7, & #8).

5. Consult your skid steer Operator’s Manual to

determine which hydraulic line on your attachment is

under pressure. Select customer supplied male (#4) or

female (#3) quick disconnect coupler that will mate

with your attachment’s pressure line coupling.

6. Screw selected coupler to line (#1) until tight.

7. Screw remaining coupler to line (#2) until tight.

8. Screw case drain coupler to line (#12) until tight.

9. If available, tie hydraulic hoses (#1, #2, & #12) together

with cable ties.

Skid Steer Hook-up

DANGER

!

To avoid serious injury or death:

A crushing hazard exists while hooking-up and unhooking the

attachment. Do not allow anyone to stand between attachment

and power machine while approaching or backing away from

the attachment. Do not operate lift and/or tilt controls while

someone is near the power machine and/or attachment.

WARNING

!

To avoid serious injury or death:

Check hitch fit-up frequently. An improper fit-up can cause the

attachment to come loose from the loader hitch plate and fall.

NOTE: Quick disconnect couplers (#3, #4, & #13)

are not included with the base unit. Optional

hydraulic quick couplers are available. See “Flat

Face Couplers” and “CTL/SS Coupler” on page 30

for detailed information and part numbers.

Refer to Figure 1-1 & Figure 1-4 on page 12:

How to identify hydraulic lines (#1, #2, & #12)

• Pressure Line (#1) connects to motor (#9)

• Return line (#2) connects to solenoids (#10 & #11).

• Case drain line (#12) connects to motor (#9).

NOTE: The Stump Grinder is designed for skid

steers with universal quick attach mounting system.

Loading...

Loading...