B2410

•

B2710

•

B2910

WSM,

12271

1 ENGINE

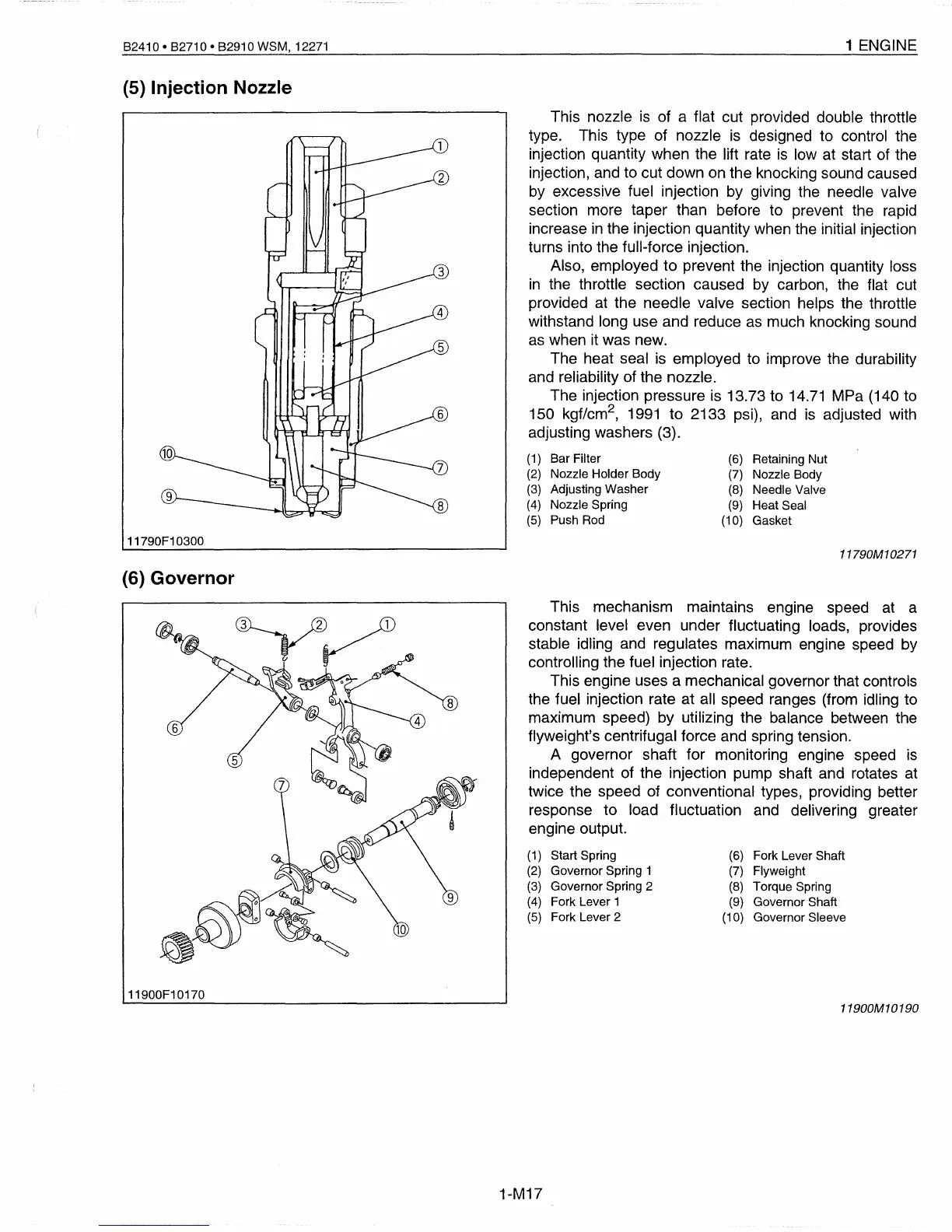

(5) Injection Nozzle

Retaining

Nut

Nozzle

Body

Needle

Valve

Heat

Seal

Gasket

(6)

(7)

(8)

(9)

(10)

This nozzle

is

of a flat cut provided double throttle

type. This type of nozzle

is

designed to control the

injection quantity when the lift rate

is

low at start of the

injection, and to cut down

on

the knocking sound caused

by

excessive fuel injection by giving the needle valve

section more taper than before to prevent the rapid

increase

in

the injection quantity when the initial injection

turns into the full-force injection.

Also, employed to prevent the injection quantity loss

in

the throttle section caused by carbon, the flat cut

provided

at

the needle valve section helps the throttle

withstand long use and reduce

as

much knocking sound

as

when

it

was new.

The heat seal

is

employed to improve the durability

and reliability of the nozzle.

The injection pressure

is

13.73 to

14.71

MPa (140 to

150 kgf/cm

2

,

1991

to 2133 psi), and

is

adjusted with

adjusting washers (3).

(1)

Bar

Filter

(2)

Nozzle

Holder

Body

(3) Adjusting

Washer

(4)

Nozzle

Spring

(5)

Push

Rod

11790F10300

11790M10271

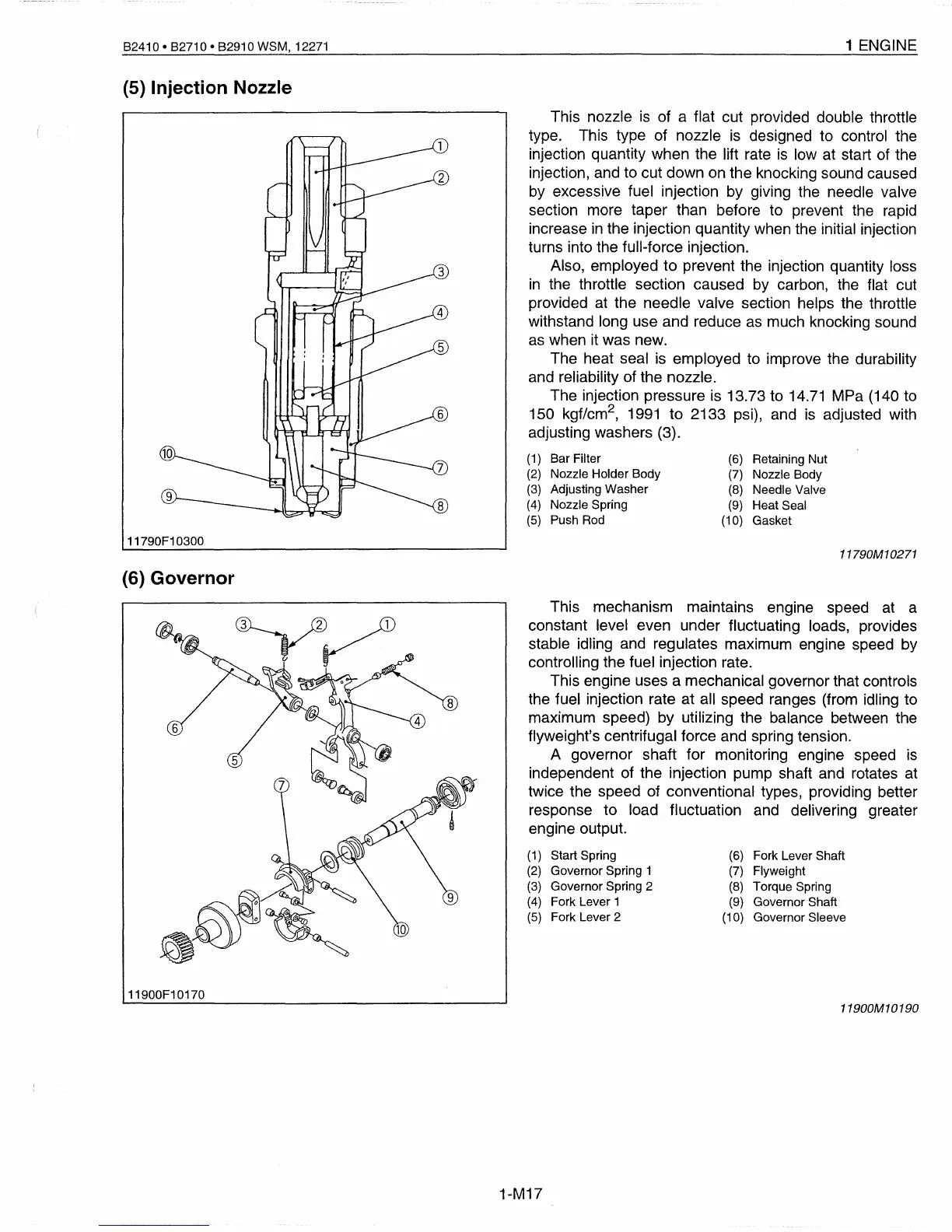

(6) Governor

This mechanism maintains engine speed

at

a

constant level even under fluctuating loads, provides

stable idling and regulates maximum engine speed by

controlling the fuel injection rate.

This engine uses a mechanical governor that controls

the fuel injection rate at all speed ranges (from idling to

maximum speed) by utilizing the balance between the

flyweight's centrifugal force and spring tension.

A governor shaft for monitoring engine speed

is

independent of the injection pump shaft and rotates at

twice the speed of conventional types, providing better

response to load fluctuation and delivering greater

engine output.

(1

)

Start

Spring

(6)

Fork

Lever

Shaft

(2)

Governor

Spring

1

(7)

Flyweight

(3)

Governor

Spring

2

(8)

Torque

Spring

(4)

Fork

Lever

1

(9)

Governor

Shaft

(5)

Fork

Lever

2

(10)

Governor

Sleeve

11900F10170

11900M10190

1-M17

Loading...

Loading...