S.l

ENGINE

BODY

92.4rnm

STROKE SERIES

WSM, 01098

Crankshaft journal

1

0

D.

A109F026

Factory

spec.

2.0441

to

2.0449

in,

51.921 to

5

1.940

rnm

A1 09F027

L

I

I

0107F070

0087F070

D087F071

I0076F034

3.9t04.1

mm

0.1

53 to0.1614

rnm

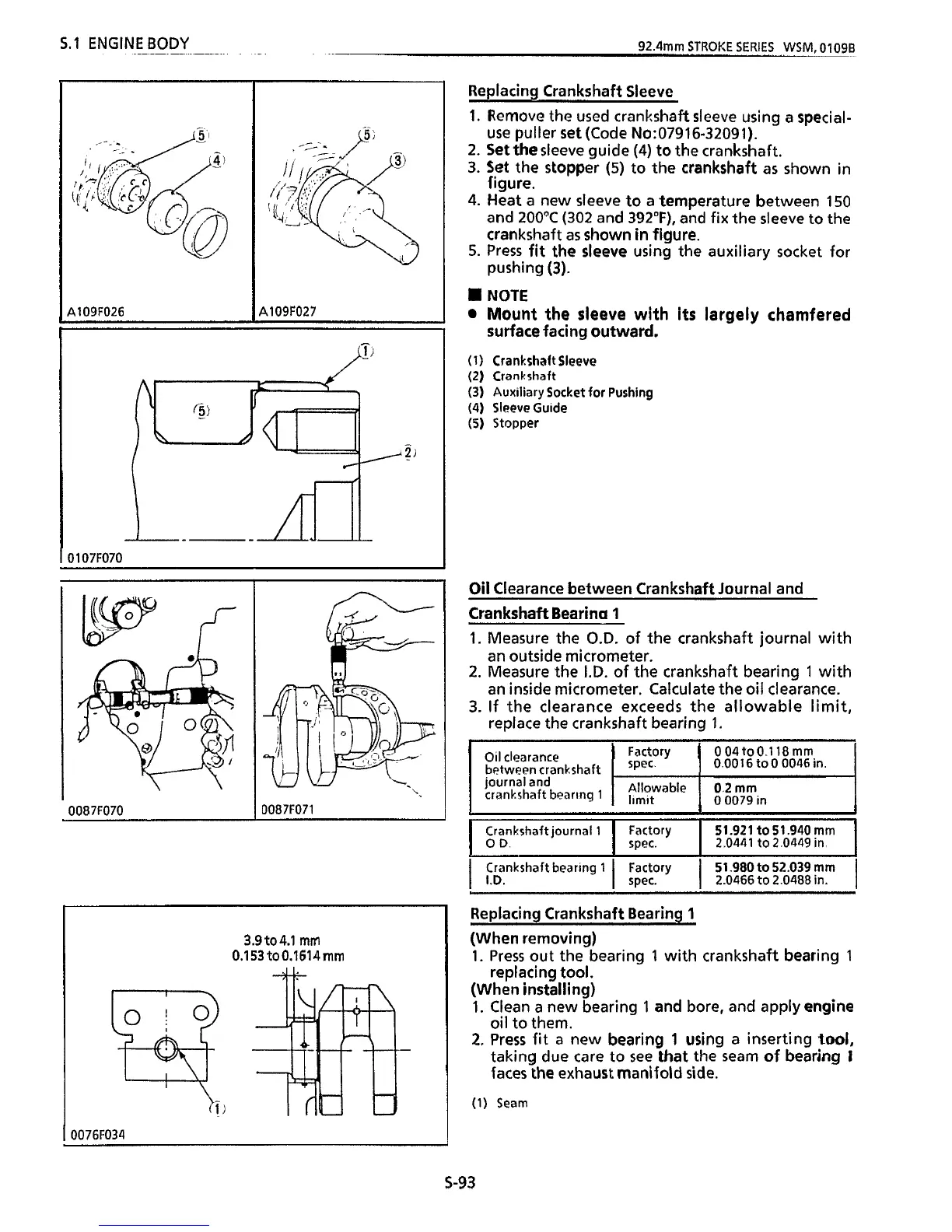

Replacing Crankshaft Sleeve

1. Remove the used crankshaft sleeve using a special-

use puller set (Code No:07916-32091).

2.

Set the sleeve guide

(4)

to the crankshaft.

3.

Set the stopper

(5)

to the crankshaft as shown

in

figure.

4.

Heat a new sleeve to a temperature between

150

and 200°C

(302

and

392"F),

and

fix

the

sleeve

to

the

crankshaft as shown

in

figure.

5.

Press

fit

the sleeve using the auxiliary socket for

pushing

(3).

NOTE

surface facing outward.

0

Mount

the sleeve with its largely chamfered

(1)

Crankshaft Sleeve

(2)

Crankshaft

(3)

Auxiliary Socket for Pushing

(4)

Sleeve Guide

(5)

Stopper

Oil

Clearance between Crankshaft Journal and

Crankshaft Bearina

1

1.

Measure the

O.D.

of the crankshaft journal

with

an outside micrometer.

2.

Measure the

I.D.

of

the crankshaft bearing

1

with

an inside micrometer. Calculate the

oil

clearance.

3.

If

the clearance exceeds the allowable limit,

replace the crankshaft bearing

1.

Factory

0

04

toO.118mm

0.0016

to0

0046

in.

0

0079

in

Oil

clearance

between crankshaft

journal and

crankshaft bearing

1

51.980

to

52.039 mrn

I

spec.

Factory

I

2.0466

to

2.0488

in.

I

I

Crankshaft bearing

1

I.D.

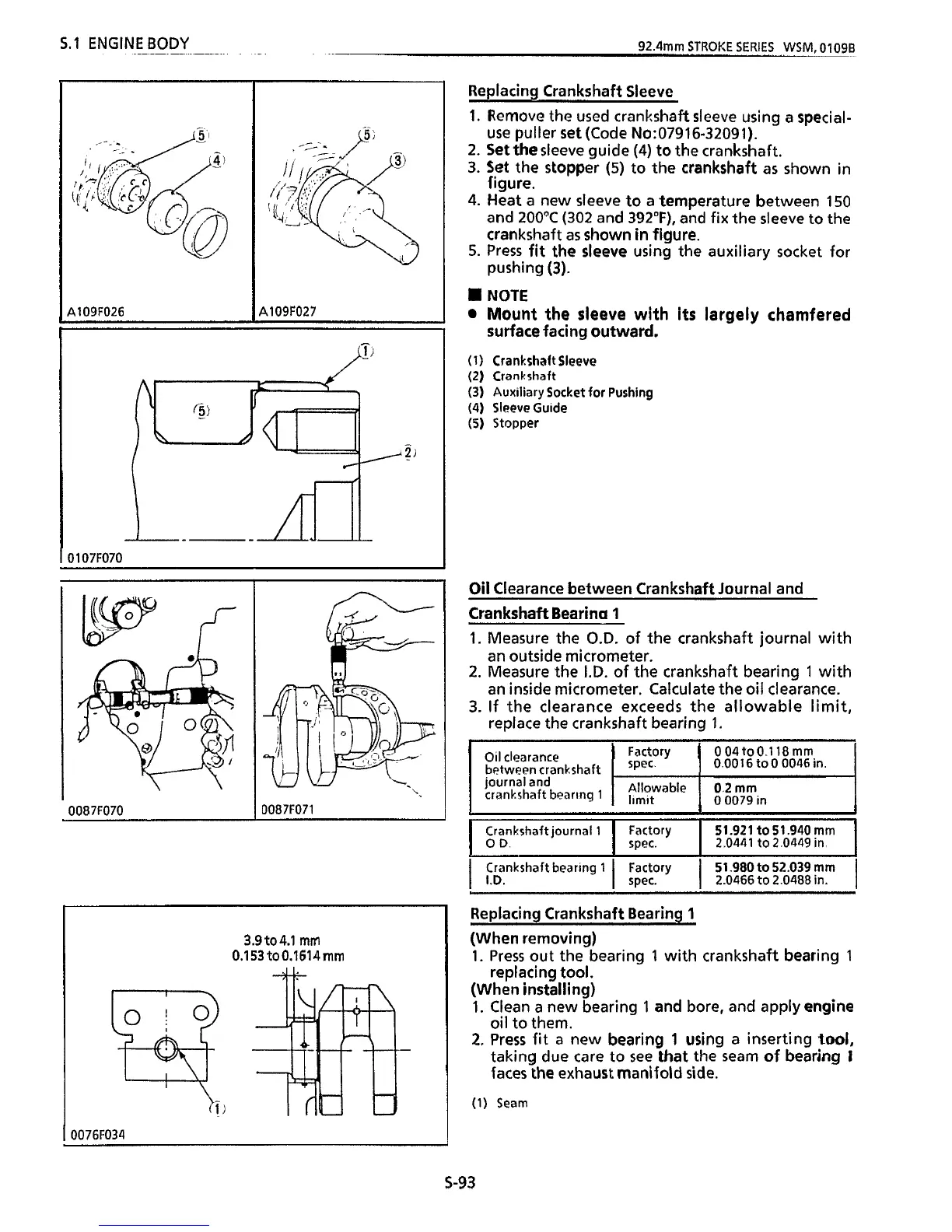

Replacing Crankshaft Bearing

1

(When removing)

1.

Press out the bearing 1

with

crankshaft bearing 1

replacing tool.

(When installing)

1. Clean a new bearing 1 and bore, and apply engine

oil to them.

2. Press

fit

a new bearing 1 using a inserting tool,

taking due care to see that the seam of bearing

1

faces the exhaust manifold side.

(1)

Seam

5-93

Loading...

Loading...