S.4

FUEL

SYSTEM

68

mm STROKE

SERIES

WSM, 01 160

E!

FUEL

SYSTEM

CHECKING AND ADJUSTING

[I]

INJECTION NOZZLE

CAUTION

Check the nozzle injection pressure and condition after confirming

that

there

is

nobody standing in the

direction the fume goes.

If

the fume from the nozzle directly contacts

the

human body,

cells

may be destoroyed and blood

poisoning may be caused.

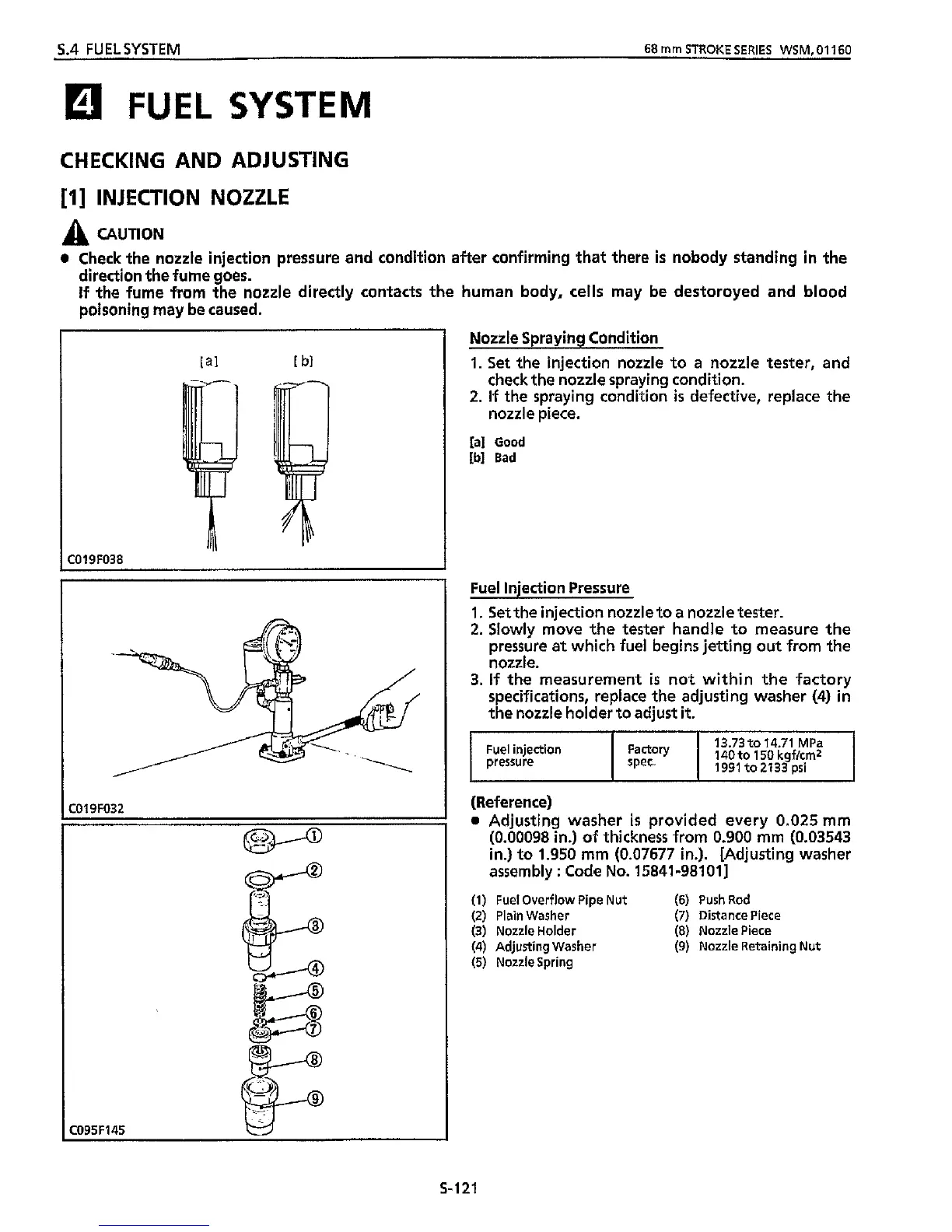

Nozzle Spraying Condition

1.

Set

the injection nozzle to

a

nozzle tester, and

2.

If

the spraying condition

is

defective, replace the

[a]

Good

Ibl

Bad

check the nozzle spraying condition.

nozzle piece.

I

C019F038

I

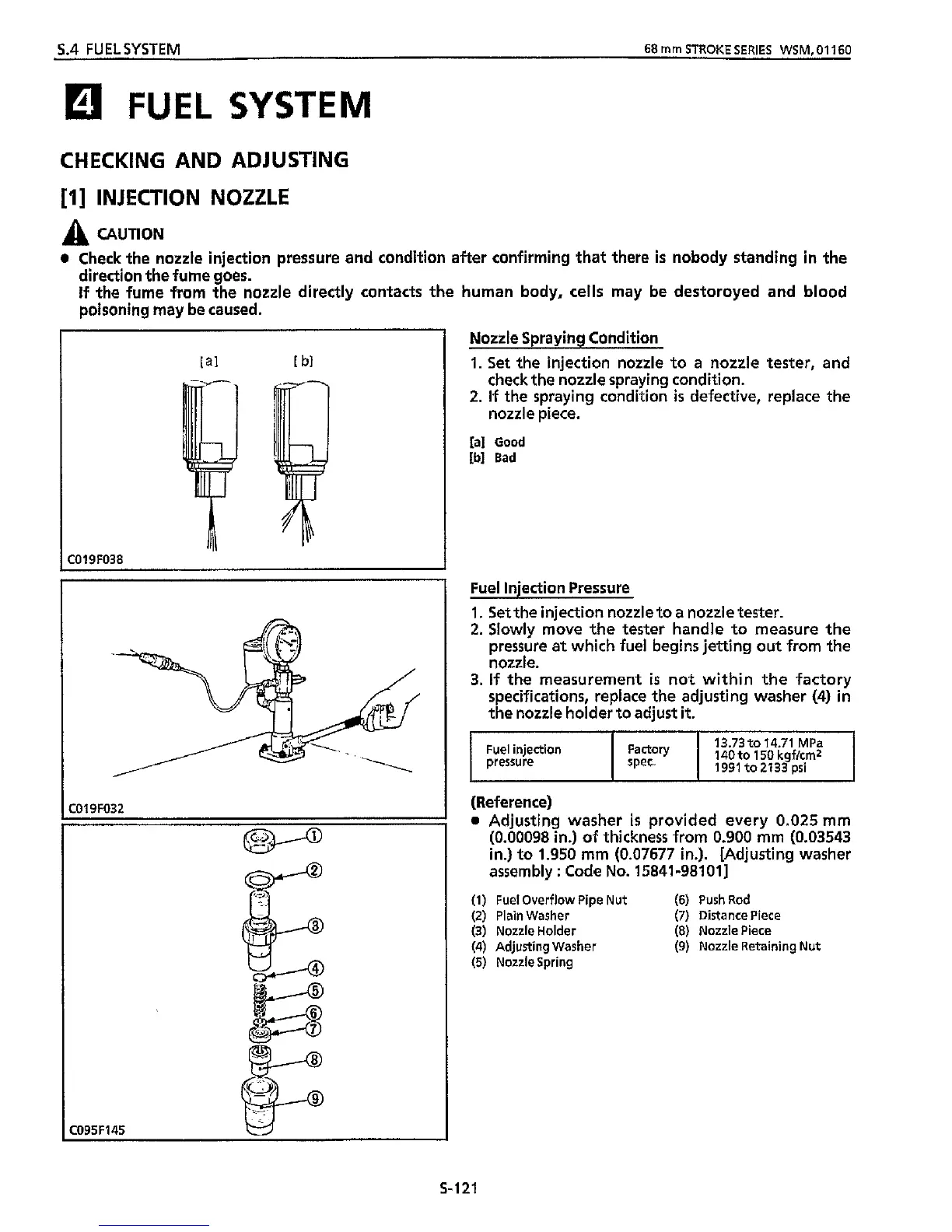

Fuel Injection Pressure

1.

Set

the injection nozzle to

a

nozzle tester.

2.

Slowly move the tester handle to measure the

pressure

at

which fuel begins jetting out from the

nozzle.

3.

If

the measurement

is

not within the factory

specifications, replace the adjusting washer

(4)

in

the nozzle holder to adjust

it.

1

EO1

9F032

C095F145

13.73to 14.71 MPa

140

to

150 kgfkmz

1991 to2133 psi

Fuel injection

pressure

(Ref

e

rence)

m

Adjusting washer

is

provided every 0.025 mm

(0.00098 in.) of thickness from 0.900 mm (0.03543

in.) to 1.950 mm

(0.07677

in.). [Adjusting washer

assembly

:

Code

No.

15841-98101

J

(1) Fuel Overflow Pipe Nut (6) PushRod

(2) Plain Washer

(7)

Distance Piece

(3) Nozzle Holder

(8)

Nozzle Piece

(4)

Adjusting Washer

(9)

Nozzle Retaining Nut

(5)

Nozzle Spring

5-121

Loading...

Loading...