9 of 17

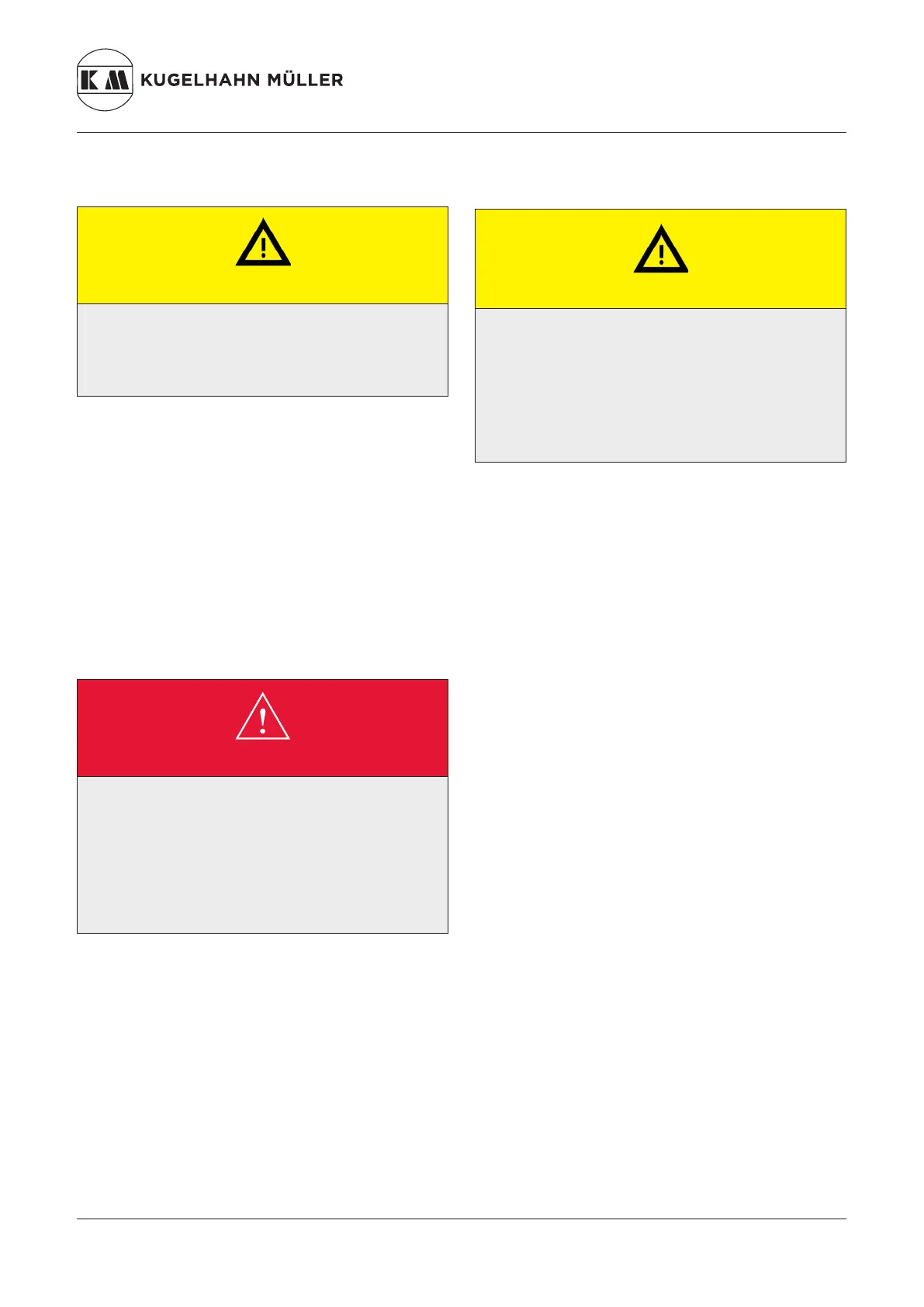

SERIES: KM-O(ST) & KM-T(ST)

Operating and maintenance instructions

2.3 SAFETY NOTES ON INSTALLATION,

OPERATION AND MAINTENANCE

DANGER

Failure to observe the following cautions and warnings

may result in danger, invalidating manufacturer's warranty.

In case of any questions please contact the manufacturer.

See back for addresses.

Ball valves are subject to the same safety regulations as the

pipe system into which they are installed and the control

system to which the actuator is connected. Additional

safety notes may also be included in the instructions of the

actuator assembly.

The manufacturer is not responsible and therefore, before

using the ball valve, it must be ensured that

> after installation into a pipe system, these ball valves are

exclusively used to shut off or transport fluids within the

approved pressure and temperature limits.

DANGER TO LIFE

It is not allowed to install a valve whose approved

pressure/temperature range (= "rating") is not sufficient

for the operating condition.

The approved range is described in the planning

document > Pressure and temperature applications.

See last page for reference address

Failure to observe this regulation may present a danger.

> the valve is only installed by personnel qualified to

perform work on pipes under pressure. (Qualified

personnel within the meaning of these instructions are

persons who are able to properly assess and perform

any task associated with the valve and anticipate or

recognize any possible dangers and eliminate them as

quickly as possible)

DANGER

Protection against incorrect use of ball valve:

In particular, it must be ensured that the selected materials

of the wetted ball valve parts are suitable for the fluids in

the pipe section. Failure to observe these precautions may

present a danger to the user and cause damage to the pipe

system.

> the ball valve is installed and operated in such a way

as supplied by the manufacturer Kugelhahn Müller.

Any changes performed without the approval of the

manufacturer (except the retrofitting of an actuator)

are not allowed and relieve manufacturer of his product

liability.

> an actuator unit subsequently attached to a ball valve

is adapted to the ball valve and correctly adjusted in its

end positions, particularly in open position,

> the pipe system and control system for the actuator

(if any) have been properly installed and are

subject to regular checks. The design of the wall

thickness of the ball valve body takes the usual

additional pipe load Fz into account for such a

properly laid pipe system (Fz = π/4*DN²*PS).

(PS = maximum permissible design pressure – see type

plate in section 3).

> the usual flow rates in this pipe system are not

exceeded during continuous operation and abnormal

operating conditions such as vibrations, water

hammers, cavitation, decomposition of unstable fluids,

earthquake and increased content of solids in the fluid,

particularly abrasive solids, have been clarified with the

manufacturer Kugelhahn Müller.

> the valve is correctly connected to this system,

> the pipe system has the required free space for operation

and for disassembly/assembly for the purpose of

inspection or maintenance.

Loading...

Loading...