Rev: 08.04.2017

Page 13

Kwikee® 888 Electric Step Owner's Manual

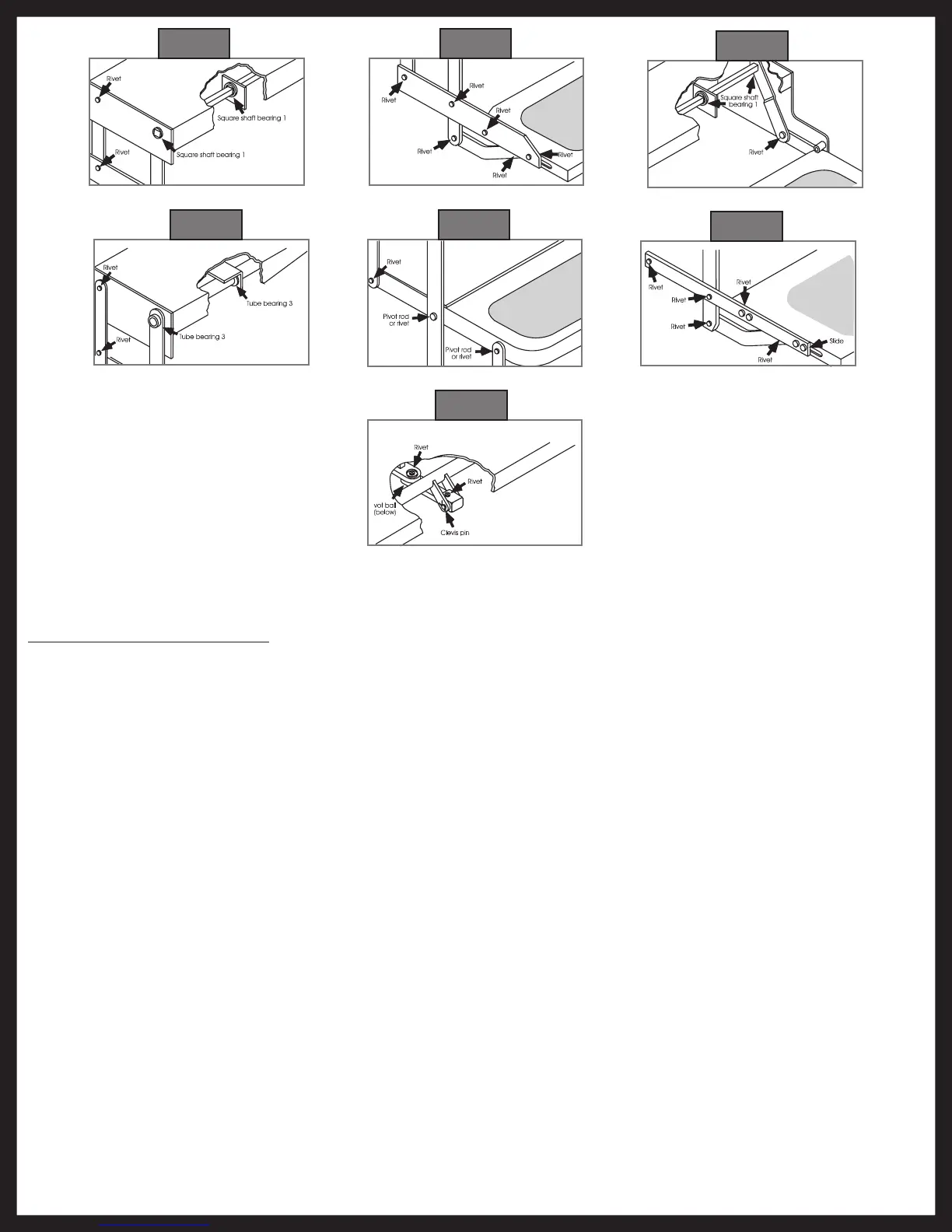

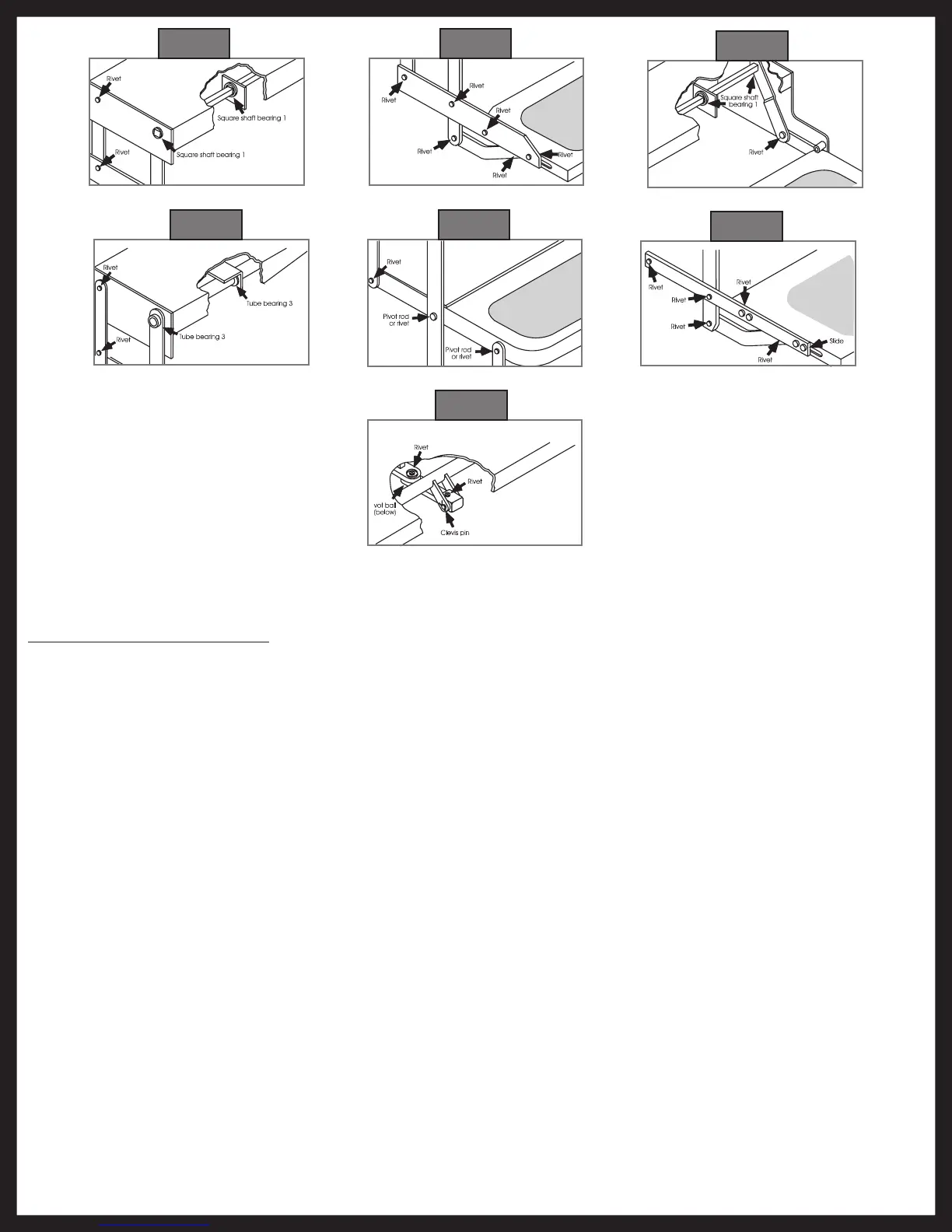

Fig. 11

Fig. 12

Fig. 13

Fig. 14 Fig. 15

Fig. 16

Fig. 17

Maintenance

Step Assembly Lubrication

Clean all mud, salt, and road grime from the step before lubricating. Lubricate all moving parts (bearings,

pivot points, slides, clevis pin, and drive linkage ball) every 30 days with a good quality moisture and heat

resistant penetrating grease. KwikLube™ Spray Grease is specially formulated to lubricate Kwikee Electric

Steps and is recommended for lubricating all moving parts. See figures 11-17 for lubrication locations.

NOTE: Silicone lubricants and WD-40 are not recommended for use. They have a tendency to evaporate

and dry the mating surfaces which leave them vulnerable to the elements.

NOTE: Figures 11-17 are to be used for general reference purposes only. Some may not pertain to your

particular step model.

1. For square shaft bearings, lubricate around outside and under head of bearings (Fig. 11 and Fig. 13).

2. On step models equipped with a plastic cover, this cover will have to be removed to lubricate center

bearings (Fig. 14). Lubricate bearings under cover every 90 days (Fig. 14).

3. Lubricate around the bushing-in-bushings (Fig. 14).

4. Maintain clean, dry electrical connections at the 2-way and 4-way connectors and any butt connections

leading from the 4-way connector to the vehicle. A small dab of dielectric grease at the connections

and replacing corroded butt connections with heat shrink type crimp style automotive connectors will

help maintain a good electrical source for the step.

Loading...

Loading...