2NM/2NX/2NY/2NZ/2P0/2P6

1-4-76

(3) Image is too light.

Print example Cause of trouble

1. Variance in environments (dew formation).

2. Toner is under supplied, or deteriorated in quality.(Under charged)

3. The volatage of the developing bias is too low.

4. The volatage of the transfer current is too low.

5. The power of LSU laser is too low.

6. The surface potential of the drum is too high.

7. The contact pressure at the trasnfer roller and the drum is too low.

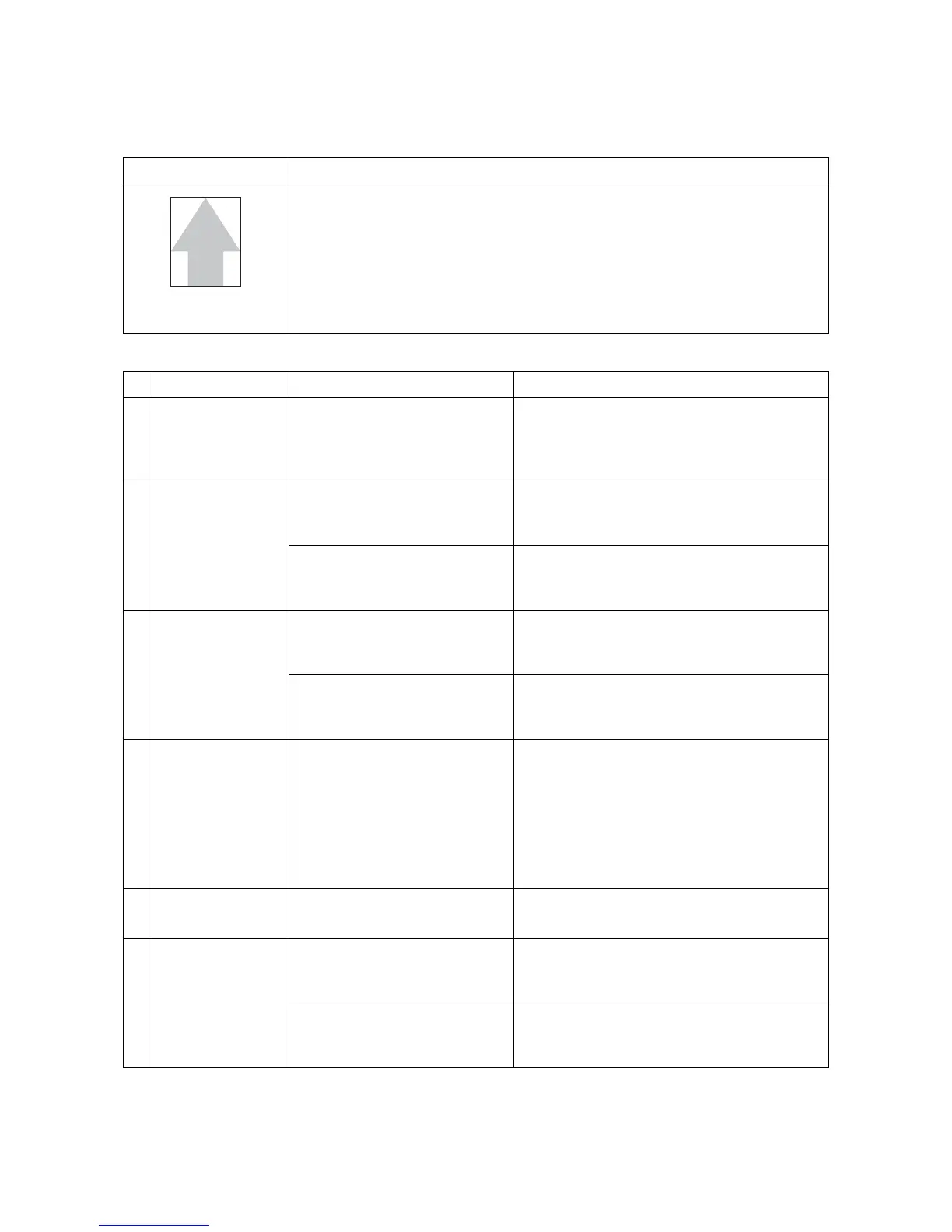

Defective part Check description Corrective Action

1

Paper

Check that the paper has mois-

ture absorbed. Check that the

paper has stored in a humid

place.

If the paper is damp, replace.Choose a dry

place to store paper.

2

Drum unit

Check that the drum has dew

condensation.

If a dew condensation is observed, perform

drum refreshing.

(System Menu >Adjustment / Maintenance)

1. Check if the discharging

lamp is dirty.

2. Check whether it is lit.

1. If the discharging lamp is dirty, clean.

2. If not cured, or it does not light, replace the

drum unit.

3

Developer unit

1. Generate PGs by service

mode and check the follow-

ing : (see page 1-3-105)

2. Check if the connecting ter-

minals for developer bias are

deformed.

If the connecting terminals are deformed, cor-

rect for a proper conduction.

4

Toner container Shake the toner container up

and down approx. 10 times, and

check the following:

1. Check remaining toner by

the indicator.

2. Check whether the toner

supply inlet is open.

If the message prompting toner replenishing is

shown, the toner inlet is not open, replace the

toner container.

5

High voltage PWB

Replace the high voltage PWB.

6

Transfer roller unit

1. Check whether the connect-

ing terminals.

1. If the connecting terminals are deformed,

correct for a proper conduction.

2. Replace transfer roller unit.

2. Check if the contact between

the transfer roller and durm

is correct.

Re-mount the transfer roller.

Loading...

Loading...