Do you have a question about the La Marzocco Linea Classic and is the answer not in the manual?

Explains the fundamental process of forcing hot water through ground coffee using key components like boilers and pumps.

Details the function and operation of the two stainless steel boilers in La Marzocco machines.

Describes the groups as brewing chambers and the importance of maintaining their temperature.

Explains the function of solenoid valves mounted under each group for water flow control.

Details how the flowmeter measures water volume using an impeller and magnetic sensors.

Explains the system responsible for maintaining the correct water level in the steam boiler.

Describes the vacuum valve's role in preventing steam escape and ensuring accurate pressure readings.

Details the expansion valve's function in relieving front boiler pressure at approximately 12 bar.

Explains the safety relief valve's function to prevent the steam boiler from over-pressurizing.

Describes the motor pump's role in increasing water pressure for brewing espresso.

Outlines the three positions of the main power switch: off, fill, and run.

Explains how the thermostat controls the temperature of the front boiler using a bellows mechanism.

Details how heating elements in each boiler provide heat to the surrounding water.

Breaks down the control box into its constituent systems like power supply, autofill, and input.

Explains the micro pressure switch's role in controlling steam pressure and heating elements.

Step-by-step instructions for daily cleaning of espresso machine group heads and portafilters.

Procedure for daily cleaning of diffuser screens and group heads using a cleaning solution.

Detailed guide on how to remove old and install new portafilter gaskets correctly.

Instructions on how to turn off power, remove panels, and loosen a bleeder screw to relieve an airlock.

Guidance for authorized technicians on checking the flowmeters of the espresso machine.

Procedure for authorized technicians to inspect and check the espresso machine's group valves.

Instructions on inspecting the brewing system for leaks, focusing on group valve and expansion valve.

Routine service recommendation for the steam valve, to be performed by an authorized technician.

Guide on inspecting and adjusting pump and expansion valve pressures for optimal performance.

Addresses issues when the espresso machine fails to produce steam, focusing on clogged steam tips.

Components for maintaining steam boiler water level: solenoid, probe, control box.

Valve to shut off steam flow to the steam valve assembly and wand for service.

Semi-permeable filter in the portafilter holding back coffee grounds.

Microprocessor controlling water volume on AV/espresso machines via menu pad.

Sharp plates that grind coffee to desired coarseness; flat or conical.

Menu pad button for activating and deactivating continuous water flow.

One-way valve preventing hot water backflow into water supply lines.

Spreads water flow evenly over espresso in portafilter insert.

Weight of coffee dispensed into portafilter, typically 7 grams.

Resistive coil inside boilers providing heat when electricity passes through.

Gasket sealing heating element to boiler end to prevent leaks.

Gasket on group head underside for portafilter seal.

General description for the coarseness of ground coffee used for espresso.

Provides ground reference for the autofill system.

Removable top cover on groups containing thermal limiter and bleed screw.

Brewing head of the La Marzocco, filled with water for thermal stability.

Six-bladed wheel in flowmeter body with magnets for signaling the control box.

Delicate graphite blades spinning rapidly to force water into the machine.

Menu pad offering pre-programmed drink options and programming capabilities.

Handled device to hold ground, tamped coffee for brewing.

Attachment at portafilter bottom directing espresso into cups.

Three-way switch applying power for dosing, filling, and heating elements.

Measures steam and brewing pressure in bars.

Force applied to coffee in portafilter for desired shot time.

Dissolved mineral solid (calcium/lime) accumulating in machine, causing damage.

Clear glass allowing operator to view water level in the steam boiler.

Converts electrical energy into magnetic field to move valve plunger.

Rubber-sealed piston sealing valve seat to control water flow.

Handheld device for applying pressure to ground coffee before brewing.

Device regulating temperature by controlling electricity to the brewing boiler element.

Stainless steel nozzle used to direct steam into milk.

Device that relieves excess pressure from the brewing system.

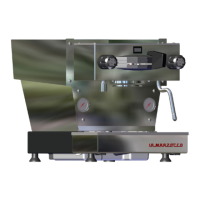

| Body Material | Stainless Steel |

|---|---|

| Steam Wand | Yes |

| Hot Water Dispenser | Yes |

| Boiler Material | Stainless Steel |

| Pump Type | Rotary |

| Power Requirements | Varies by model, please consult the official documentation |

| Power Consumption | Varies by model, please consult the official documentation |

| Water Tank Capacity | N/A (plumbed in) |

Loading...

Loading...