Maintenance 95

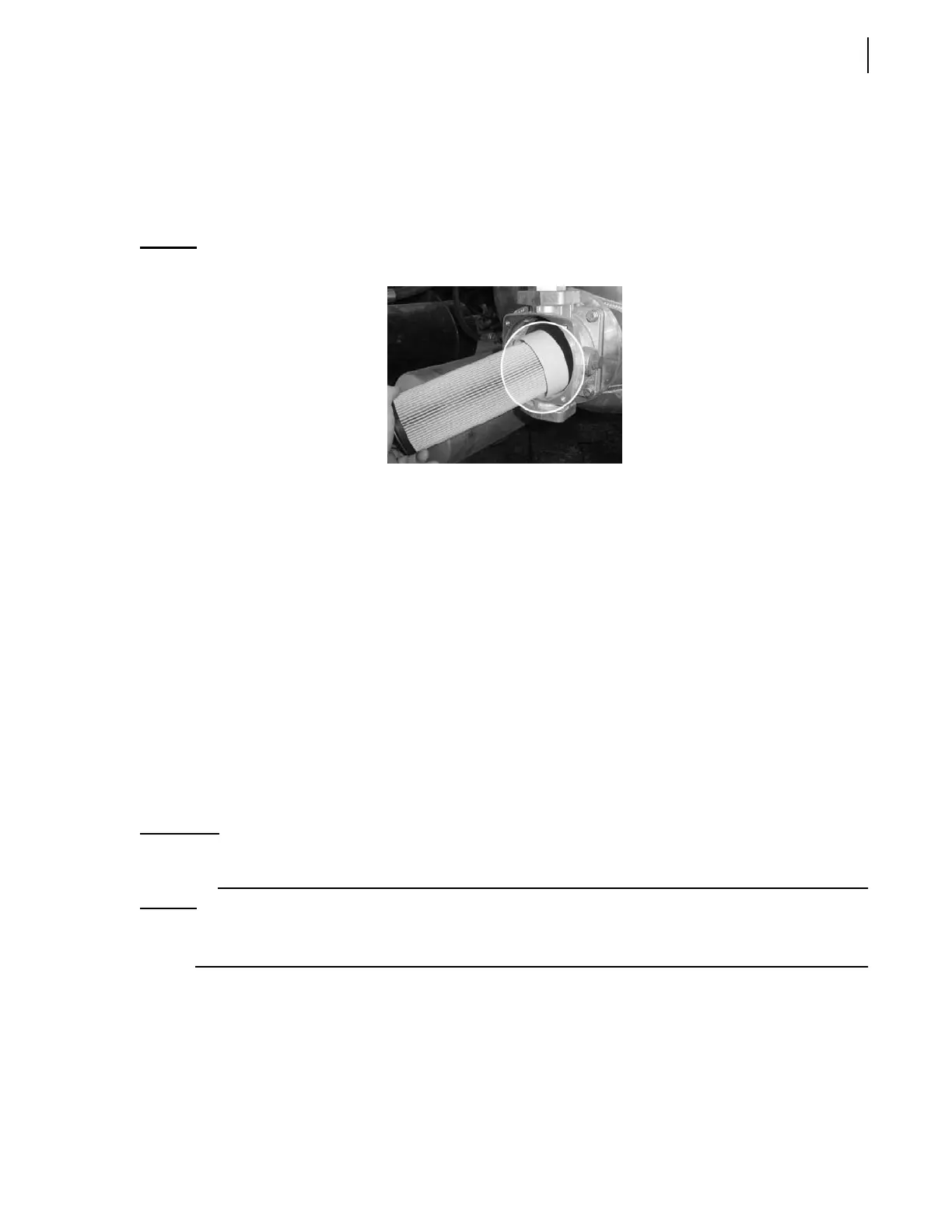

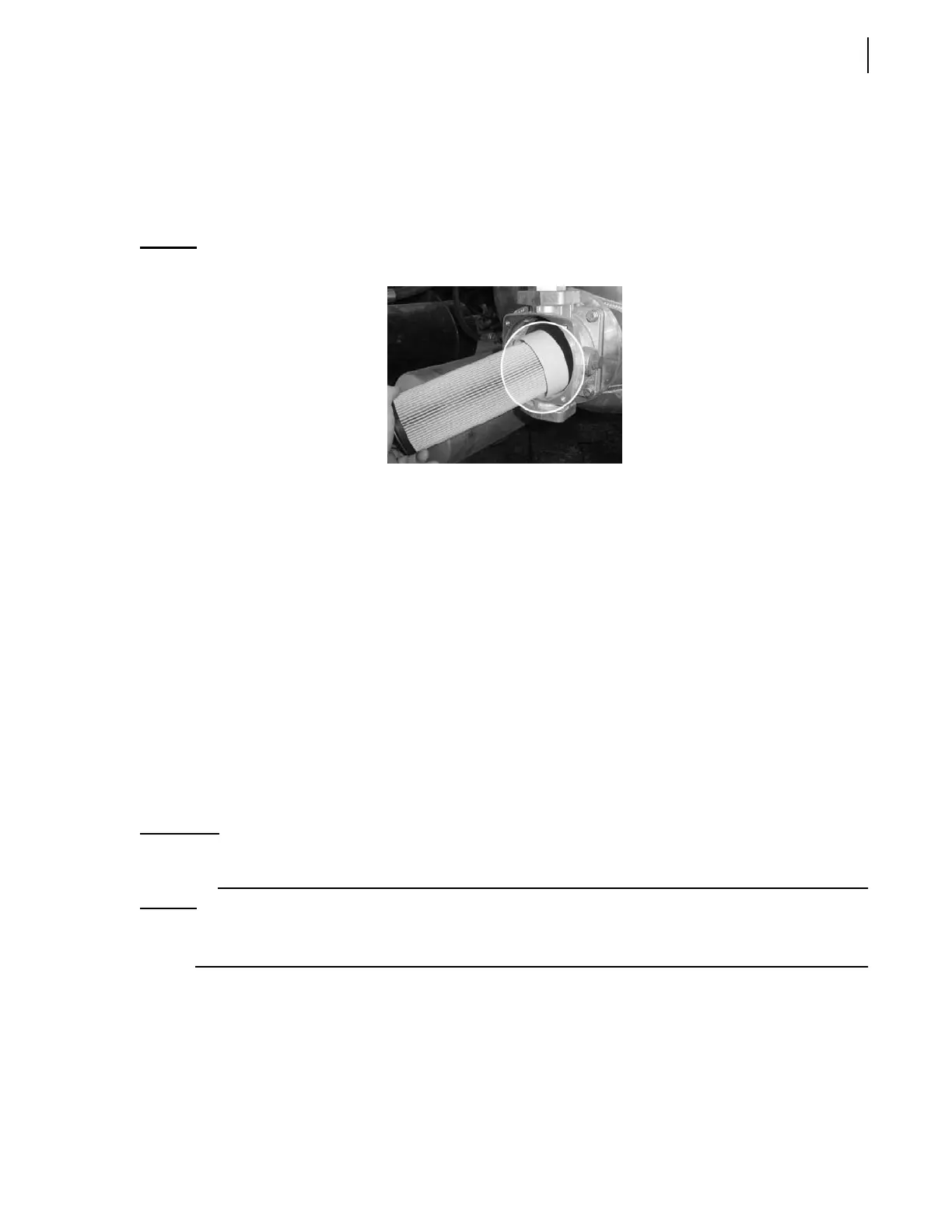

Return Line Filter Element

While every effort is made at the Labrie Enviroquip Group factory to ensure clean hydraulic systems,

it should be noted that most hydraulic system manufacturers recommend the filter be replaced after a

break-in period. Labrie’s recommendation is to replace this filter element after a break-in period of

50 hours operational use.

Figure 3-35

Return line filter element

Routine Maintenance

Routine element replacement will ensure that contaminants trapped due to ingestion and component

wear are removed from the system by maintenance.

The replacement interval may be determined by operational duty cycle, operating conditions and

local maintenance schedules.

Labrie Enviroquip Group recommends the filter element be replaced every 1000 hours operational

use. Refer to “Maintenance Checklist” on page 50.

The element must also be changed following a major hydraulic component failure.

Element Replacement Procedure

To replace the return line element:

1. Complete the lockout/tagout procedure (see Lockout/Tagout Procedure on page 37).

IMPORTANT: Keep tools, working area and equipment clean. A pan will be required to collect a small amount of

oil lost as the element is removed.

NOTE: The filter housing is fitted with a check valve, therefore it is not necessary to drain the

hydraulic tank.

2. Release system pressure by slowly removing the hydraulic tank cap.

3. Loosen the 4 cover plate screws, rotate through 45

o

and lift off.

Loading...

Loading...