3

Leave12inches(305mm)ofextratubingbelowthe

counterforservicingandmovingthedispenser

NOTE

Selecting/Preparing Counter Location

4. Condenser air is drawn in from the front half of the top cover,

and discharged out the rear half of the top cover. A minimum

of eight (8) inches (203 mm) clearance must be maintained

over the top of the unit to provide for proper air ow and

circulation.

Unit Installation

1. Remove bonnet and front plate from the unit.

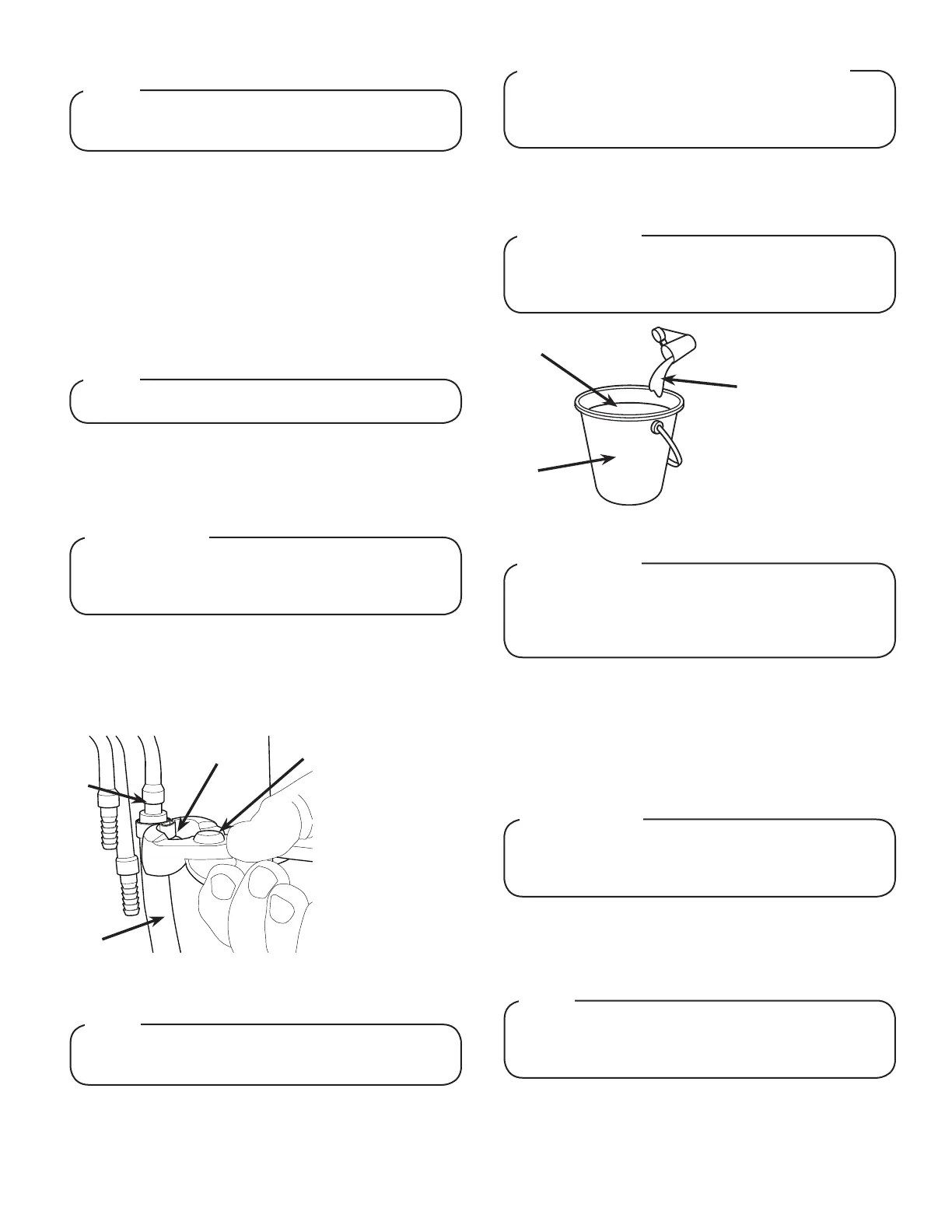

2. Route appropriate tubing from the syrup pump location to the

syrup inlets. Connect tubing to inlets using the oetiker pliers

and ttings. Repeat for all syrup connections.

4. Flush water supply line thoroughly.

7. Using a conductivity meter, measure the electric conductivity

of the distilled water mixture.

Failuretomaintainspeciedclearancewillcausethe

compressortooverheatandwillresultincompressor

failure

! ATTENTION

Carefullyreadthisbeforellingthewaterbathtank.

Inordertooptimizethemaximumperformanceofthe

dispenser,thefollowingMUSTbeadheredto:

! CRITICAL - to maximize performance

Forproperfunctionoftheelectronicicebankcontrol

thetotaldissolvedsolids(TDS)measurementsshould

be300-500ppm.

! ATTENTION

TheE.C.measurementofthedistilledwatermixture

mustbebetween100and300uS/cm.Below100uS/cm,

thecompressorwillnotworkproperlyandabove300

uS/cmcouldcausethelinestofreeze.

! ATTENTION

NSFlistedunitsmustbeinstalledwithlegsprovided.

NOTE

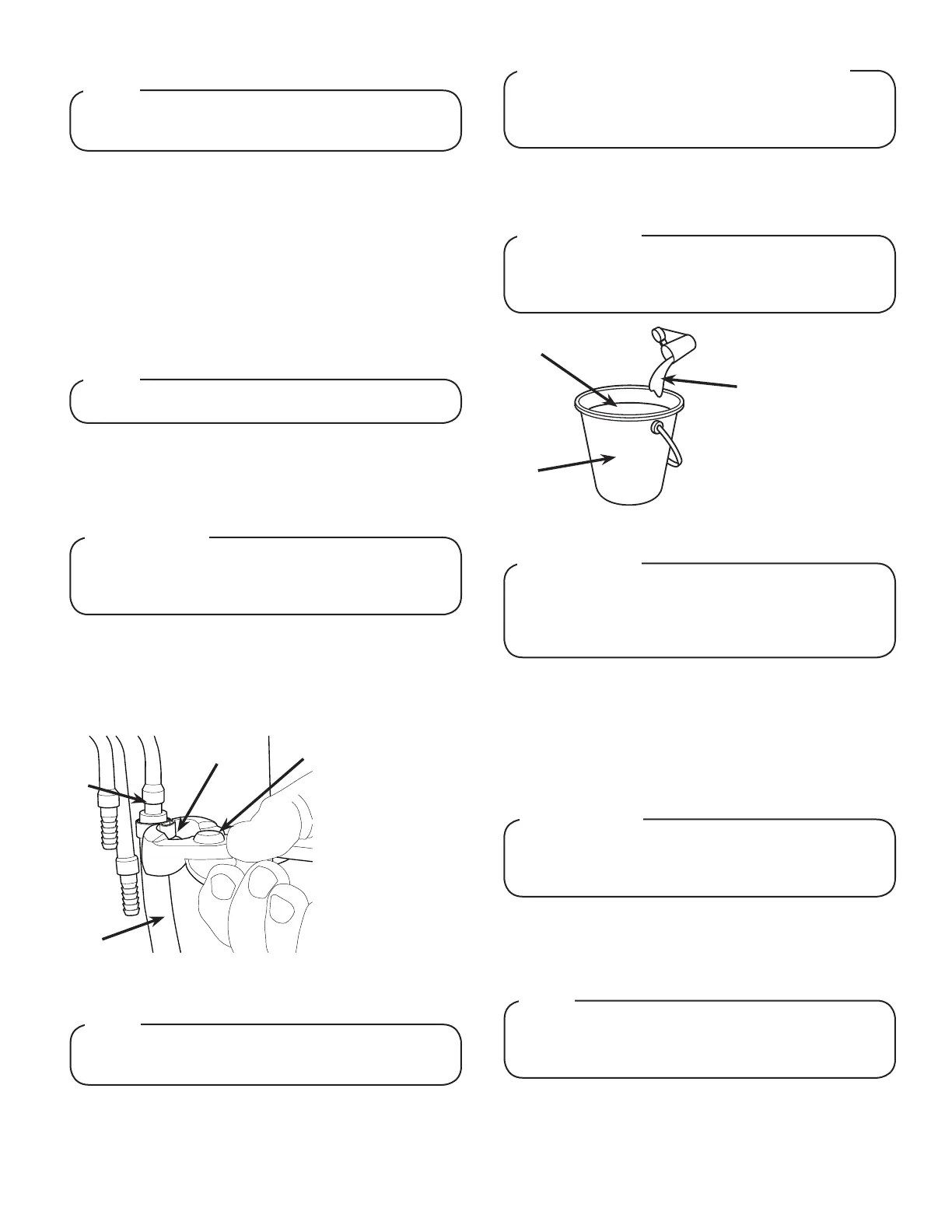

5. Insert water line into a large bucket, and ll with approx. 5.4

gallons (20.4 L) of distilled water.

6. Add 1/8 oz (4 g) of baking soda to distilled water and stir.

1. The unit is designed to sit on a at, supported surface

capable of supporting a minimum weight of 400 lbs (182

kg). Select a location that is in close proximity to a properly

grounded electrical outlet and a water supply that meets the

requirements shown in the Specications section found on

previous page.

2. Select a location for the syrup pumps, CO

2

tank, syrup

containers, water lter (recommended), and remote

carbonator.

3. The unit is designed to be mounted with legs. If leg kit has

been provided, assembly legs by tilting unit.

Thedispensershouldonlybeinstalledinalocation

whereitcanbeoverseenbytrainedpersonnel

NOTE

A

B

C

A. Oetiker Pliers

B. Fitting

C. Tubing

D. Syrup/Water/CO

2

Inlet

D

3. Route appropriate tubing from the water source to the

compressor deck ll hole, identied by the yellow cap, and

ONLY connect tubing to water source.

A

B

C

A. Bucket

B. Distilled Water

(approx. 5.4 gal)

C. Baking Soda

(approx. 1/8 oz)

UsethePlumbingDiagramsonpages12-15to

determinewhichvalvesaretobeplumbedwithplain

waterorcarbonatedwater

NOTE

8. Remove yellow cap from the water bath ll hole and insert

and insert a funnel into the ll hole.

9. Remove the insulation strip from front of the refrigeration

deck.

10. Carefully pour the distilled water mixture into the water bath

tank until water ows out of the overow tube at the front of

the unit. (Repeat steps 9-11 if needed)

Thewaterbathcompartmentmustbelledwithwater

beforepluggingintheunit,otherwisethecompressor

fan may not operate properly.

! ATTENTION

11. Replace yellow cap, replace insulation, then connect water

line to the carbonated water inlet in the front of the unit.

12. If plain water is to utilized for any of the valves, install a “U”

tting to the water line and connect to plain water inlet.

Loading...

Loading...