4

Leave12inches(305mm)ofextratubingbelowthe

counterforservicingandmovingthedispenser

NOTE

Thelengthofthepythonmustnotexceed25feet(8

meters)ifbuilt-insyruppumpsarebeingused.

NOTE

Ifplainwaterisnotwanted,removethebarbedtting

andshortextensiontting,cancapendofplainwater

linewithcapfromaccessorykit.

NOTE

Theindividualbarbedttingsforthelinescanbe

removedforinsertionintothepythontubingby

removingthe“U”shapedretainerpinandpullingthe

ttingoofthesyrupline.

NOTE

Ifplainwaterisnotwanted,spliceastainlesssteel,

reducing,barbedhosetee(PN01-0527)inthe3/8inch

sodaline.Useaseparate1/4inchtubetocompletethe

connectionfromthebarbedteetothetowermanifold.

NOTE

DONOTinsulateconnectionsatthistime.Leaveall

connectionsexposedforinspectionofleaks.

NOTE

14. Turn on water supply and check for leaks

15. Plug in the unit to a grounded electrical outlet then turn the

unit on to begin building an ice bank.

Thedispensermustbeproperlyelectricallygrounded

toavoidseriousinjuryorfatalelectricalshock.The

powercordhasathree-pronggroundedplug.Ifa

three-holegroundedelectricaloutletisnotavailable,

useanapprovedmethodtogroundtheunit.Followall

localelectricalcodeswhenmakingconnections.Each

dispensermusthaveaseparateelectricalcircuit.Do

notuseextensioncords.Donotconnectmultiple

electricaldevicesonthesameoutlet.

! WARNING

13. Route appropriate tubing from the syrup pump location to the

CO

2

inlet and connect tubing to CO

2

inlet.

Installing Remote Syrup Pumps

1. Install BIB rack and remote pumps according to manufactur-

ers’ instructions.

2. Once pumps and BIB rack are installed, measure and cut

tubing to length between the pump CO

2

inlets, then connect

tubing to all pumps.

Installation to Dispenser

1. Determine the appropriate length of insulated python tubing

required, allowing additional length as required for servicing.

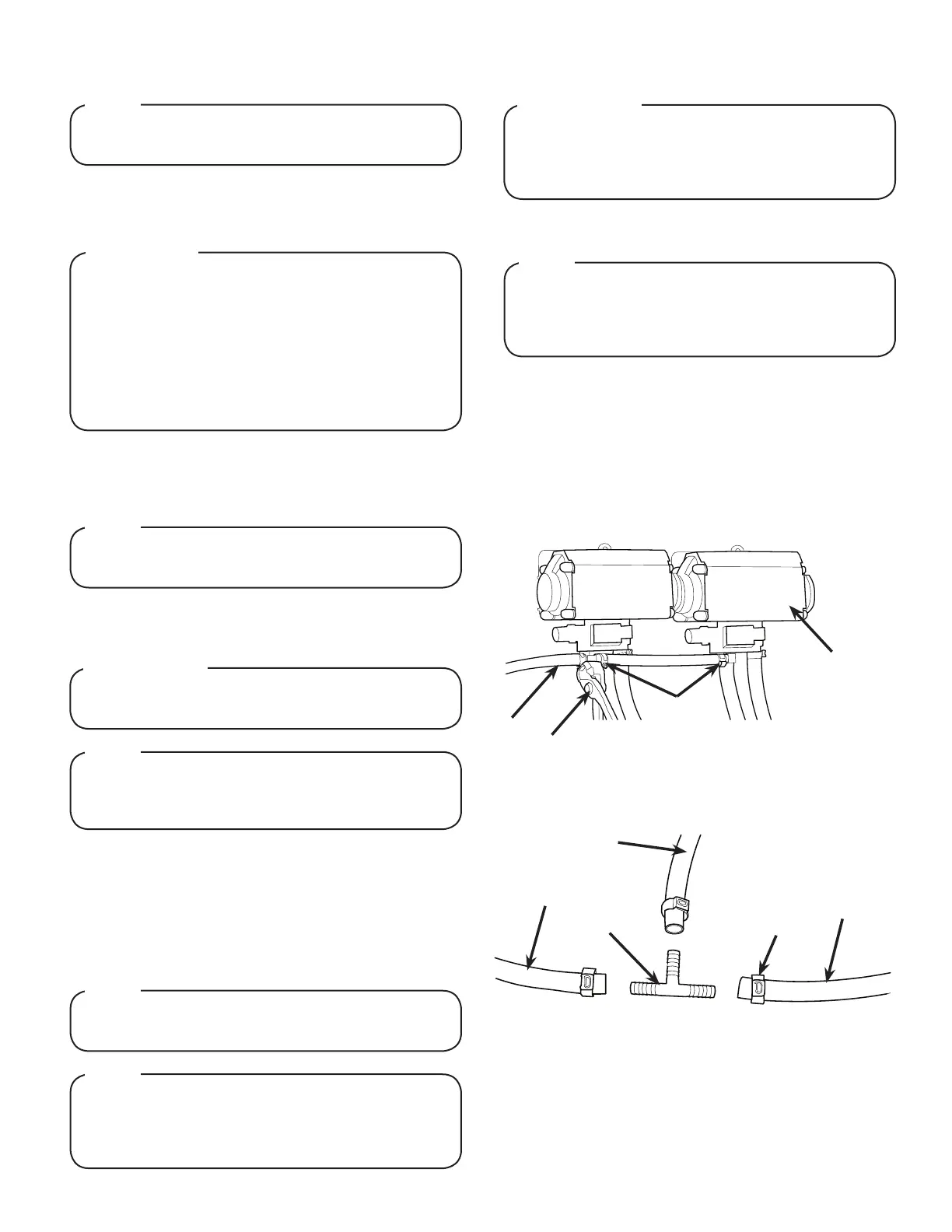

A

B

C

A. Syrup Pump

B. CO

2

Line

C. Fitting

D. Oetiker Pliers

D

3. Using tubing cutters, cut any pump CO

2

supply line and

install tee tting, then route appropriate tubing from the CO

2

supply to the tee tting at syrup pumps.

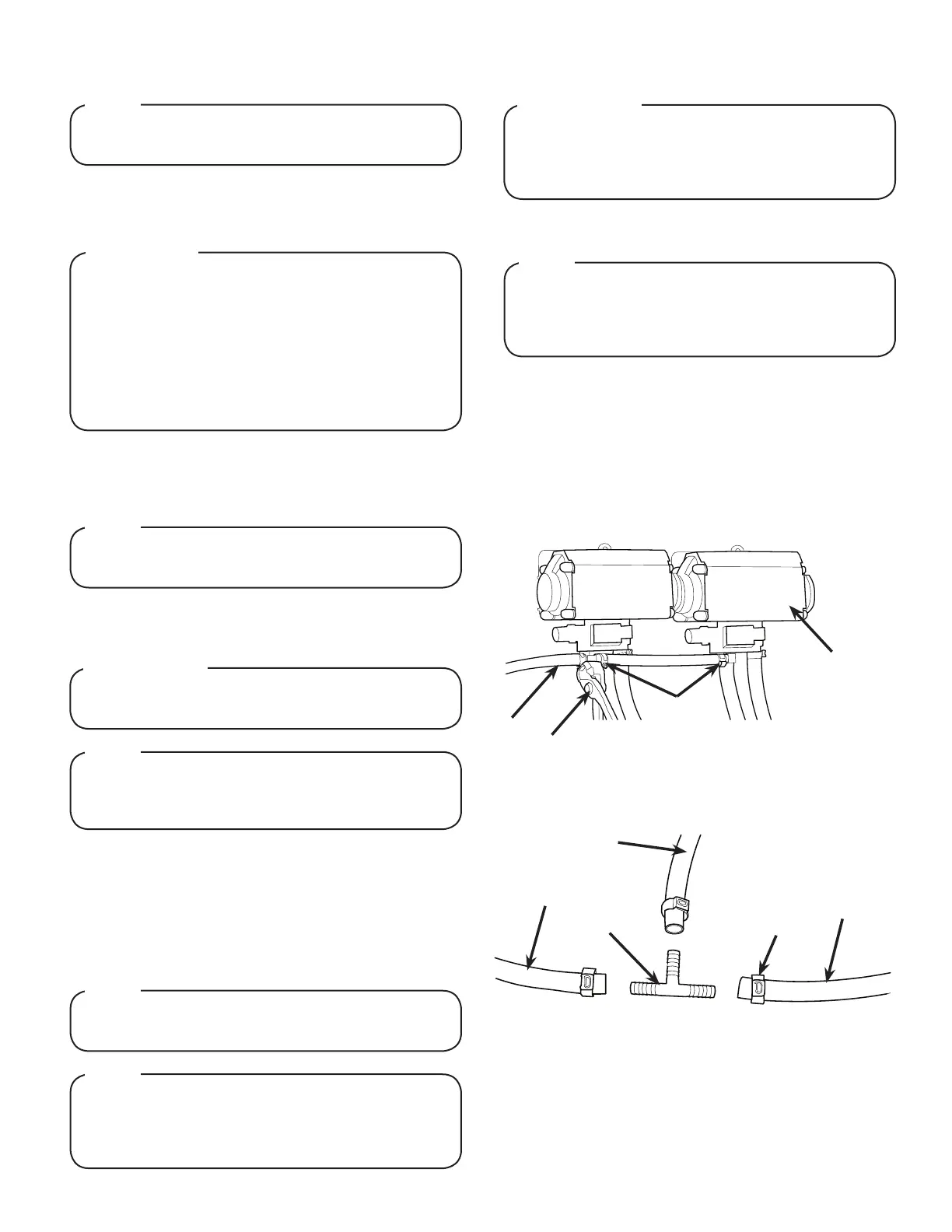

A. Tee Fitting

B. Line to Syrup Pump

C. Fitting

D. Line to CO

2

Supply

A

B

B

C

D

4. Cut tubing from CO

2

supply to tee tting at syrup pumps and

install another tee tting.

5. Attach line from dispenser CO

2

inlet to tee tting between

syrup pumps and CO

2

supply.

6. Connect tubing from dispenser syrup inlet to the syrup pump

outlet tting. Repeat for each syrup line/pump.

2. Position one end of the python near remote unit. Using a

sharp knife or razor, slit the python insulation back 18 inches

(46 cm) and roll insulation back to expose individual tubes.

3. Slide the tube insulation (from the accessory kit) over one of

the 3/8 inch soda lines in the python then connect line to the

90° elbow on the inlet to the recirculating pump.

4. Connect the other 3/8 inch soda line from the python to the

return inlet on the front of the unit.

5. Connect each of the 1/4 inch syrup/plain water lines to the

syrup/plain water inlets on the front of the unit.

6. Route the opposite end of the python to tower. Determine

the length required and cut if necessary.

7. Slit the python insulation back 12 inches (30 cm) and roll

insulation back to expose individual tubes.

8. Connect each of the lines from the python to the syrup, soda,

and plain water ttings on the tower manifold.

Carefulnottocuttubingbundlewhenslittingpython

insulation.

! ATTENTION

Useasharpknife,razorblade,ortubecuttertocut

tubing.Tubingcutwithasawwillresultinplastic

shavings,whichwillplugtheowcontrolsinthe

dispensing valve.

! ATTENTION

Loading...

Loading...