30

PHW SERIES PRESSURE WASHER

OPERATOR’S MANUAL

LANDA PHW • 9/02

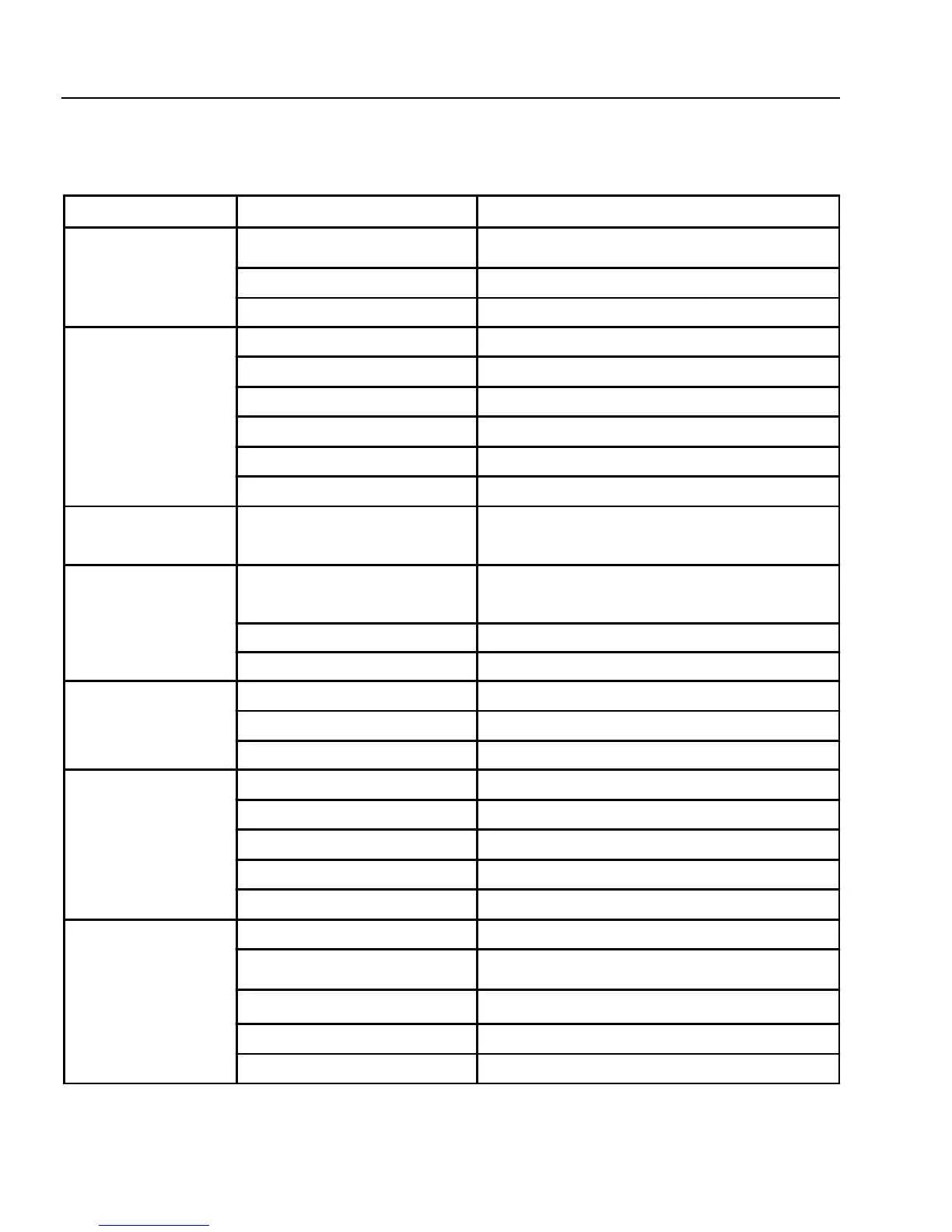

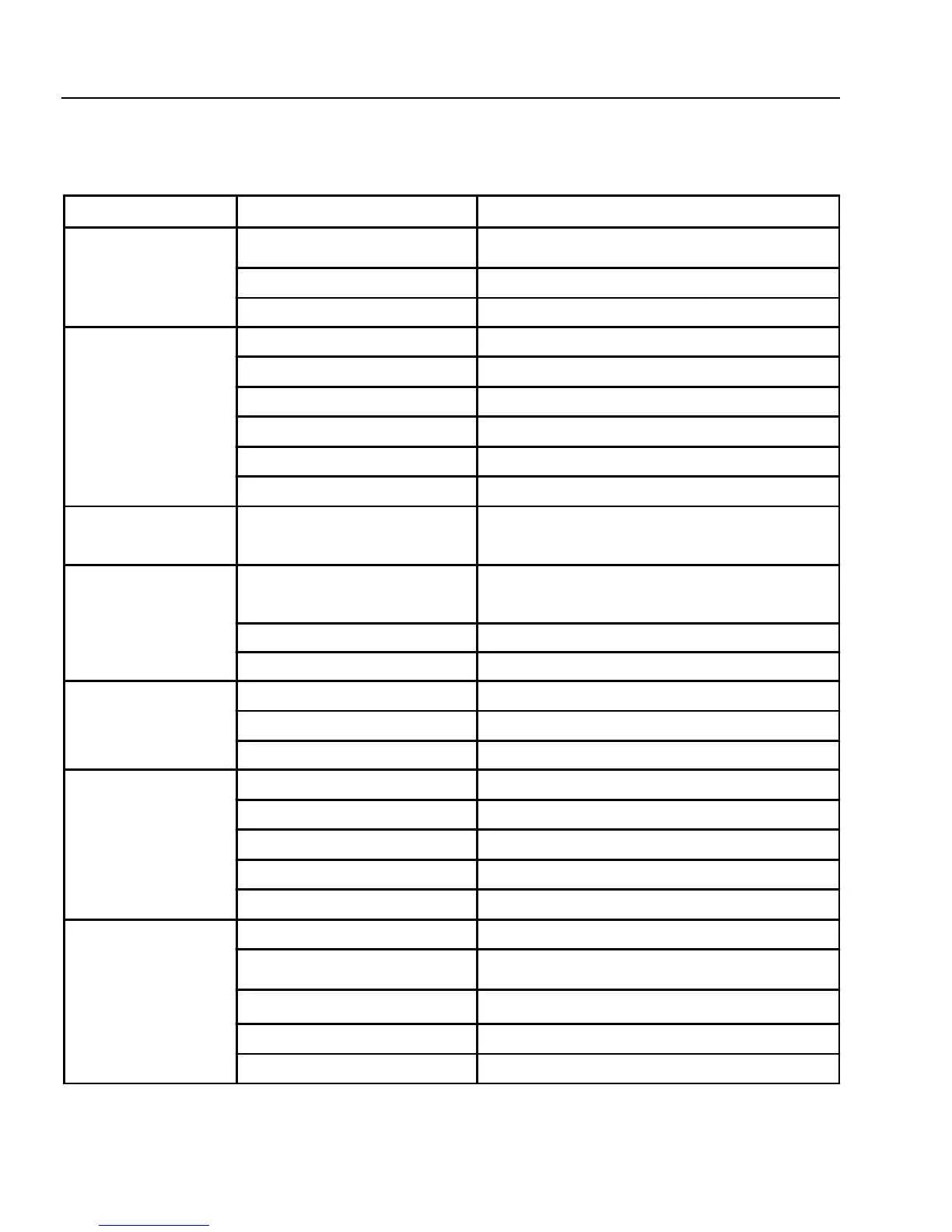

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

MACHINE WILL NOT

DRAW UP

DETERGENT

Clamps holding detergent lines

are loose

Tighten clamps.

Hole in detergent line(s) Repair hole.

Strainer basket plugged Remove and clean.

BURNER MOTOR

WILL NOT RUN

Overload protector tripped Push reset button.

Fuel pump seized Replace fuel pump.

Burner fan loose or misaligned Position correctly and tighten set screw.

Defective control switch Replace switch.

Loose wire Check and replace or tighten wiring.

Defective burner motor Replace motor.

EXCESSIVE

VIBRATION IN

DELIVERY LINE

Irregular functioning of check

valves, metering valves

Check and replace if necessary.

TEMPERATURE

RELIEF VALVE

LEAKS WATER

(pump protector)

Spray gun in OFF position with

machine operating for an

extended period of time

Open spray gun to cool circulating water.

Relief valve defective Replace valve.

Particle next to poppet Remove internal parts and clean.

BURNER STAYS ON

WHEN SPRAY GUN

IS IN OFF POSITION

Fuel pump pressure too high Call technical support.

Pressure switch defective Check for proper operation, replace if necessary.

Fuel solenoid defective Replace fuel solenoid.

PUMP RUNNING

NORMALLY BUT

PRESSURE LOW

Pump sucking air Check water supply and possibility of air seepage.

Valves sticking Check and clean or replace if necessary.

Unloader valve seat faulty Check and replace if necessary.

Nozzle incorrectly sized See serial plate for minimum nozzle size.

Worn piston packing Check and replace if necessary.

PUMP NOISY

Air in suction line Check water supply and connections on suction line.

Broken or weak inlet or discharge

valve springs

Check and replace if necessary.

Excessive temperature of liquid Reduce to below 60° C (140° F).

Foreign matter in valves Check and clean if necessary.

Worn bearings Check and replace if necessary.

Loading...

Loading...