Shenzhen Qilin Laser Application Technology Co., Ltd.

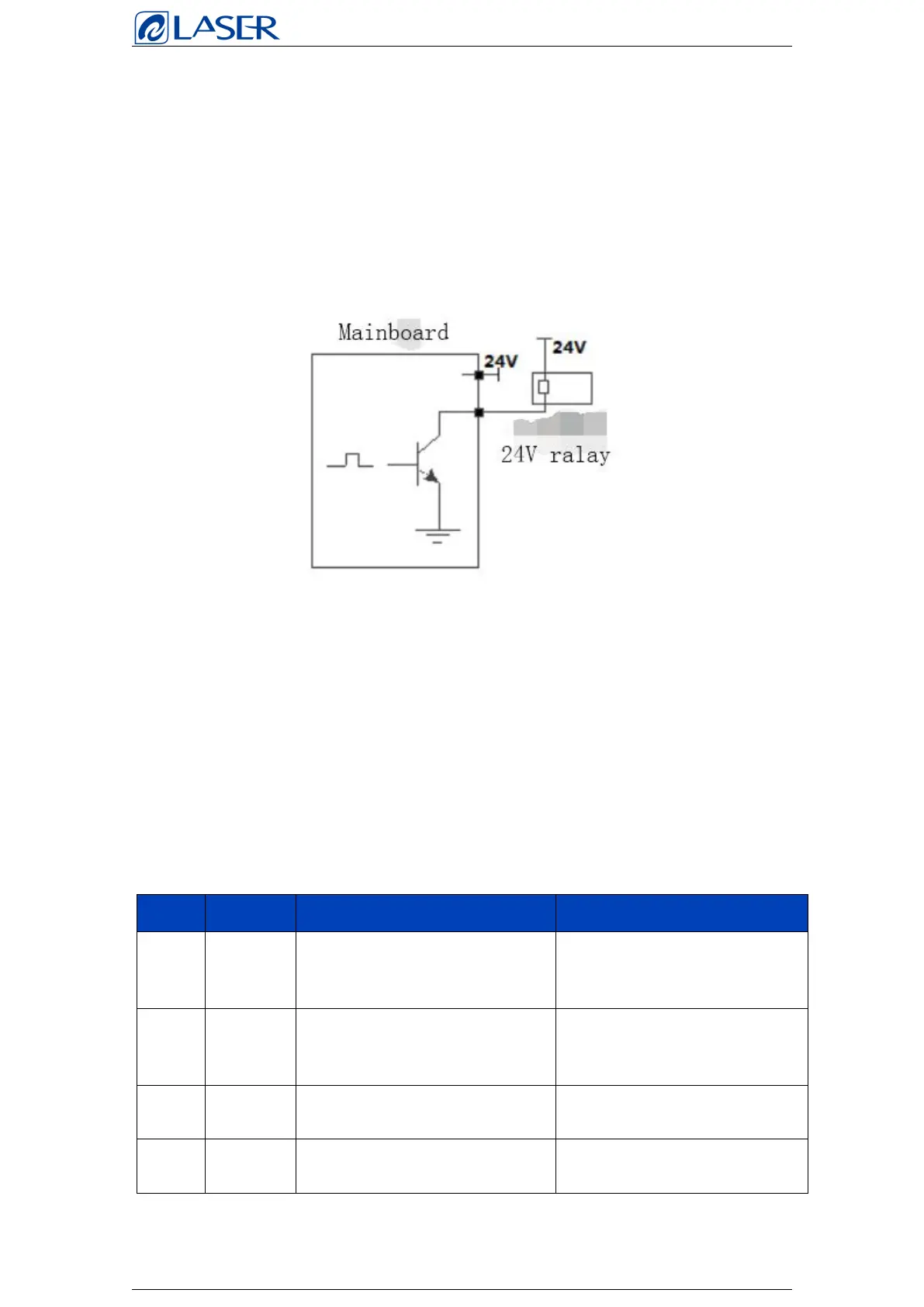

Gas control interface

Control box provides a special IO interface, all output IO using OC output can

directly drive the relay, the maximum current up to 500mA, the wiring diagram

is as follows.

Wiring diagram of outlet relay

Feeder control interface

The control box provides a specified communication interface to control wire

feeder. 3A current can be provided after 24V power supply is directly connected

to the power input interface of the control box.

*The table shows the definition of the control interface of the wire feeder.

Used to protect the gas blowing

control, positive pole

Mainboad

control relay is

recommended

Used to protect the gas blowing

control, negative pole

Connect to

negative pole of

24V relay

Wire feeder trigger signal 1

Wire feeder

control signal

Wire feeder trigger signal 2

Wire feeder

control signal

Loading...

Loading...