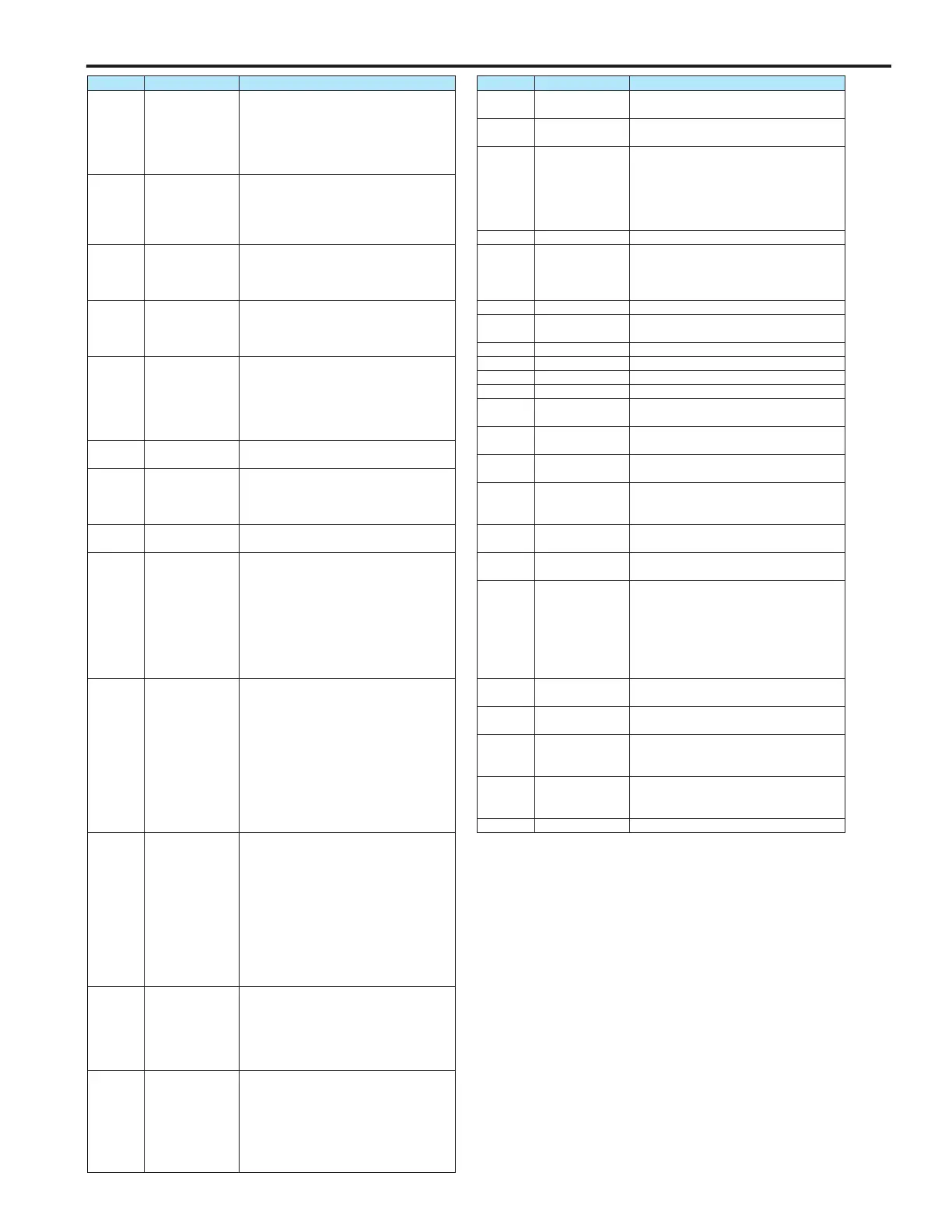

Error code Problem Possible causes

Overcurrent during

acceleration

Overcurrent flowing

in element during

acceleration

Overcurrent during

deceleration

Overcurrent flowing

in element during

decelearion

Overcurrent during

constant speed operation

Overcurrent flowing in

element during operation

Ground fault trip

Arm overcurrent at

start-up(for 11 and

15 kW models only)

Overcurrent (An

overcurrent on the

load side at start-up)

Arm overcurrent at

start-up

Input phase failure

Output phase failure

Overvoltage during

acceleration

Overvoltage during

deceleration

Overvoltage during

constant-speed

operation

Inverter overload

Motor overload

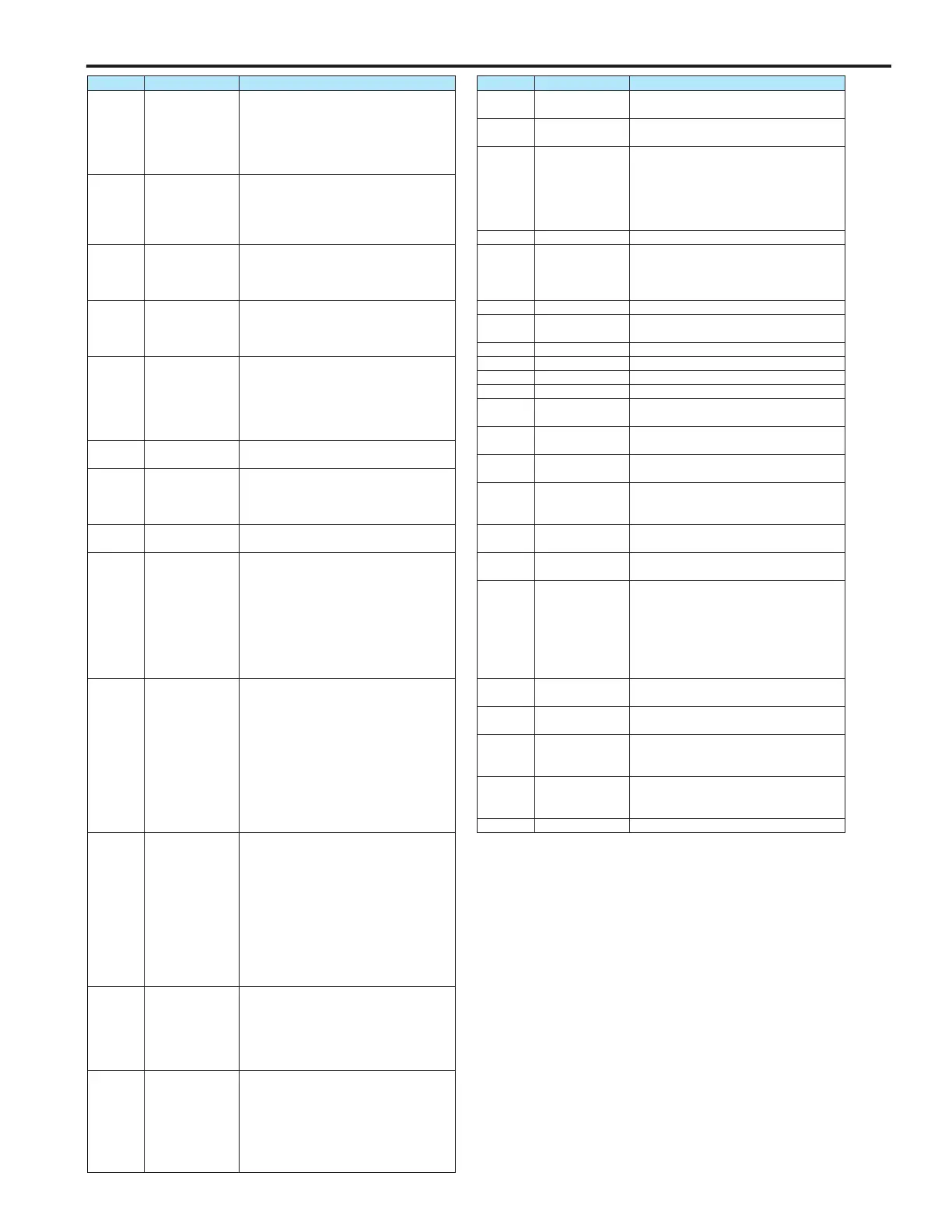

Error code Problem Possible causes

Dynamic braking

resistoroverload trip

Over-torque trip

Overheat

External thermal trip

Emergency stop

EEPROM fault 1

EEPROM fault 2

EEPROM fault 3

Main unit RAM fault

Main unit ROM fault

CPU fault 1

Remote control

error

Current detector

fault

Optional circuit

board format error

Low-current

operation

Trip

Undervoltage

trip(main circuit)

Ground fault trip

Auto-tuning error

Invertertype error

Brea in analog

signal cable

CPU

communications

error

Excessive torque

boosted

CPU fault 2

OL 1

OC IP

OC2

OC2P

OC3

OC3P

OC1P

OC2P

OC3P

OCL

OCA

*

EPHI

*

EPHO

OPI

OP2

OP3

OL1

OL2

OLr

*

Ot

OH

OH2

E

EEP1

EEP2

EEP3

Err2

Err3

Err4

Err5

Err7

Err8

*

UC

*

UPI

EF2

etnI

etyp

*

E-18

E-19

e-20

e-21

· The acceleration time acc is too short.

· The V/F setting is improper.

· A restart signal is imput to the rotating

motor after a momentary stop, etc.

· A special motor (e.g. motor with a small

impedance) is used.

· The deceleration time dec is too short.

· The load fluctuates abruptly.

· The load is in an abnormal condition.

· A current leaked from an output cable or

the motor to ground.

· A main circuit elements is defective.

· The insulation of the output main circuit or

motor is defective.

· The motor has too small impedance.

· A 11 or 15 kW model was started,

although a current is leaked from an

output cable or the motor to ground.

· A main circuit elements is defective.

· A phase failure occured in the input line of

the main circuit.

· The capacitor in the main circuit lacks

capacitance.

· A phase failure occurred in the output line

of the main circuit.

· The imput voltage fluctuates abnormally.

1. The power supply has a capacity of

200kVA or more.

2. A power factor improvement capacitor

is opened or closed.

3.

A system using a thyrister is connected

to the same power distribution line.

· A restart signal is input to the rotating

motor after a momentary stop, etc.

· The deceleration time dec is too short.

(Regenerative energy is too large.)

· f304 (dynamic braking resistor) is off.

· f305 (overvoltage limit operation) is off.

· The input voltage fluctuates abnormally.

1. The power supply has a capacity of

200kVA or more.

2. A power factor improvement capacitor

is opened and closed.

3. A system using a thyrister is connected

to the same power distribution line.

· The input voltage fluctuates abnormally.

1. The power supply has a capacity of

200kVA or more.

2. A power factor improvement capacitor

is opened or closed.

3. A system using a thyrister is connected

to the same power distribution line.

· The motor is in a regenerative state

because the load causes the motor to run

at a frequency higher than the inverter

output frequency.

· The acceleration time ACC is too short.

· The DC braking amout is too large.

· The V/F setting is improper.

· A restart signal is input to the rotating

motor after a momentary stop, etc.

· The load is too large.

· The V/F setting is improper.

· The motor is locked up.

· Low·speed operation is performed

continuously.

· An excessive load is applied to the motor

during operation.

· The deceleration time is too short.

· Dynamic braking is too large.

· Over-torque reaches to a detection level

during operation.

· The cooling fan does not rotate.

· The ambient temperature is too high.

· The vent is blocked up.

· A heat generating device is installed close

to the inverter.

· The thermistor in the unit is broken.

· An external thermal trip is input.

· During automatic operation or remote

operation, a stop command is entered

from the operation panel or a remote input

device.

· A data writing error occurs.

· Power supply is cut off during typ

operation and data writing is aborted.

· A data reading error occurred.

· The control RAM is defective.

· The control ROM is defective.

· The control CPU is defective.

· An error arises during remote operation.

· The current detector is defective.

· An optional circuit board in a different

format is installed.

· The output current decreased to a low-

current detection level during operation.

· The input voltage (in the main circuit) is

too low.

· A ground fault occurs in the output cable

or the motor.

· Check the motor parameter f401 to f494.

· The motor with the capacity of 2 classes

or less than the inverter is used.

· The output cable is too thin.

· The motor is rotating.

· The inverter is used for loads other than

those of three-phase induction motors.

· Circuit board is changed. (Or main

circuit/drive circuit board)

· The signal input via VRF is below the

analog sinal detectio level set with f633.

· A communications error occurs between

control CPUs.

· The torque boost parameter vb is set

too

high.

· The motor has too small impedance.

· The control CPU is defective.

Loading...

Loading...