DM542 Fully Digital Stepper Drive Manual DM542 Fully Digital Stepper Drive Manual

1 2

DM542

Digital two-phase stepper driver

一、Introduction

1. Overview

DM542 is the new digital stepping motor driver of our company. It adopts the latest 32-bit DSP

digital processing technology. The driver control algorithm uses advanced variable current

technology and advanced frequency conversion technology.

The driver has low heat generation,

small motor vibration and stable operation. Users can set any subdivision within 200~51200 and

any current value within the rated current, which can meet the application needs of most occasions.

With built-in micro-segmentation technology, even in the case of low subdivision, high subdivision

can be achieved, and the operation at low, medium and high speeds is smooth and the noise is

extremely small.

The parameter internal power-on auto-tuning function is integrated in the drive,

which can automatically generate optimal operating parameters for different motors to maximize

the performance of the motor.

2. Features

3. Application field

Suitable for all kinds of small and medium-sized automation equipment and instruments, such as:

engraving machine, marking machine, cutting machine, laser phototypesetting, plotter, CNC

machine tool, automatic assembly equipment, etc. It is especially effective in applications where

users expect small noise and high speed.

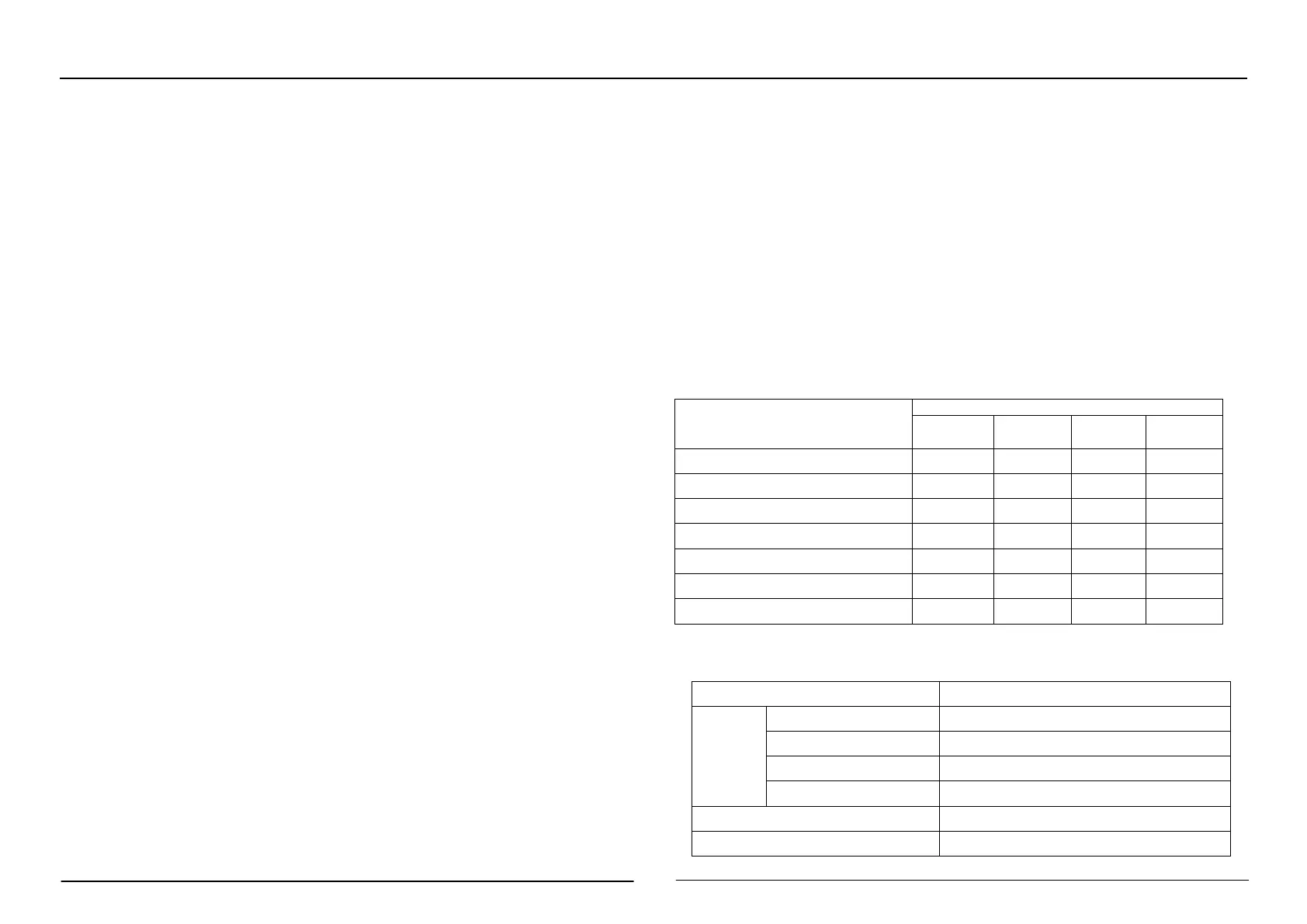

Electrical, mechanical and environmental indicators

1. Electrical index

Description

Min Typical Max Unit

Output current

0.1 - 4.2 A

Input supply voltage

24 36 50 VDC

Control signal input current

6 10 16 mA

Control signal interface level

4.5 5 28 Vdc

Input signal minimum pulse width

1.5 - - us

Step pulse frequency

0 - 200 KHz

Insulation resistance

100 MΩ

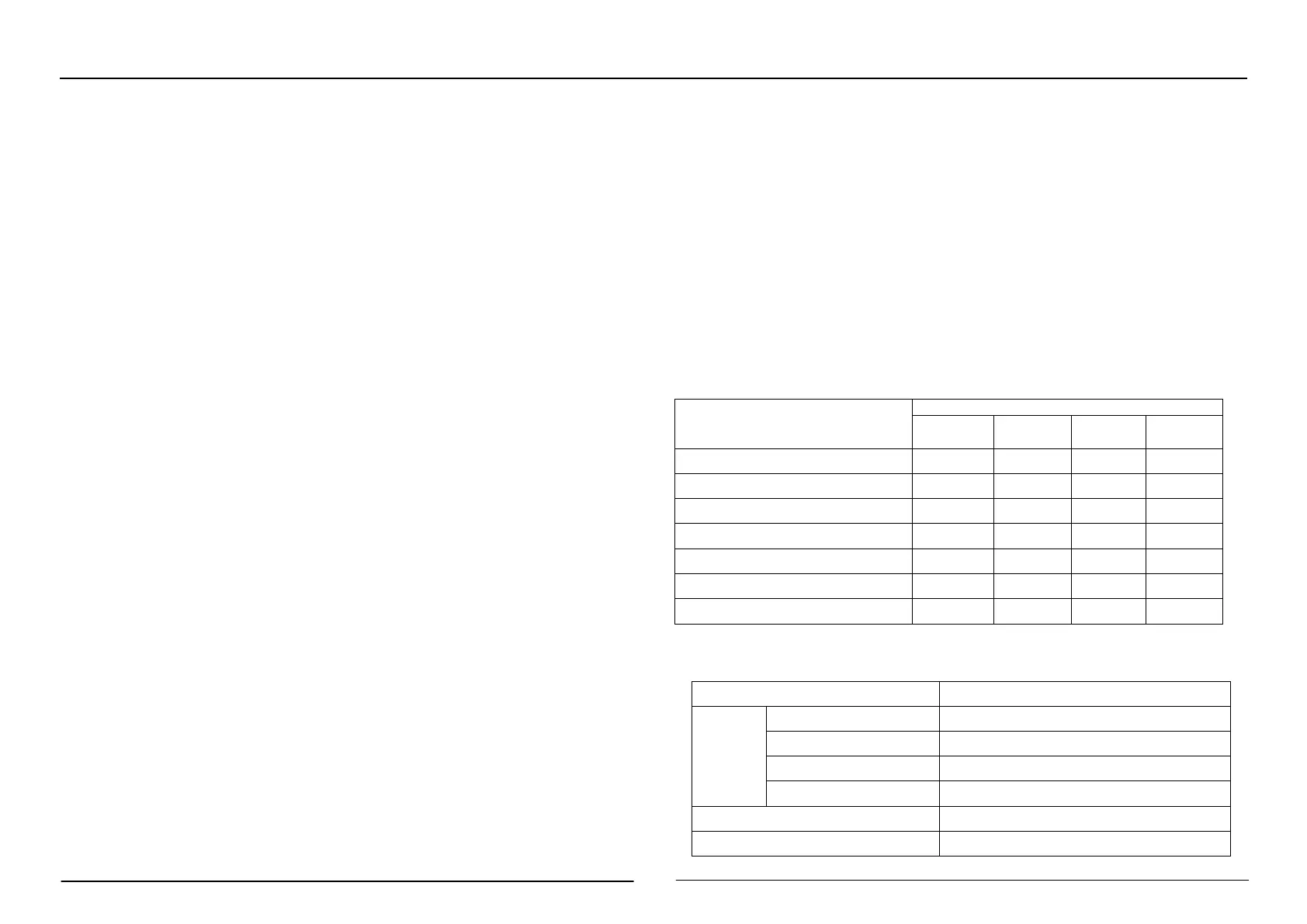

2. Operating Environment and other Specifications

Cooling Natural Cooling or Forced cooling

Operating

Environment Avoid dust, oil fog and corrosive gases

Ambient Temperature -5℃ ~ +50℃

Humidity 40 ~ 90%RH

Vibration 5.9m/s2MAX

Storage Temperature -20℃~80℃

weight

about 300 g

●

New 32-bit DSP technology

●Ultra low vibration noise

● Built-in high subdivision

● Parameter power-on auto-tuning function

● Variable current control makes the motor heat greatly reduced

●

The current is automatically halved at rest

●

4,6,8 line two-phase stepper motor

● Optically isolated differential signal input

●The impulse response frequency can reach up to 500KHz (factory default 160KHz)

●The current setting is convenient, and can be arbitrarily selected between 0.1-4.2A.

●The subdivision setting range is 200-51200

● With overvoltage, undervoltage, overcurrent protection

Loading...

Loading...