DM542 Fully Digital Stepper Drive Manual DM542 Fully Digital Stepper Drive Manual

5 6

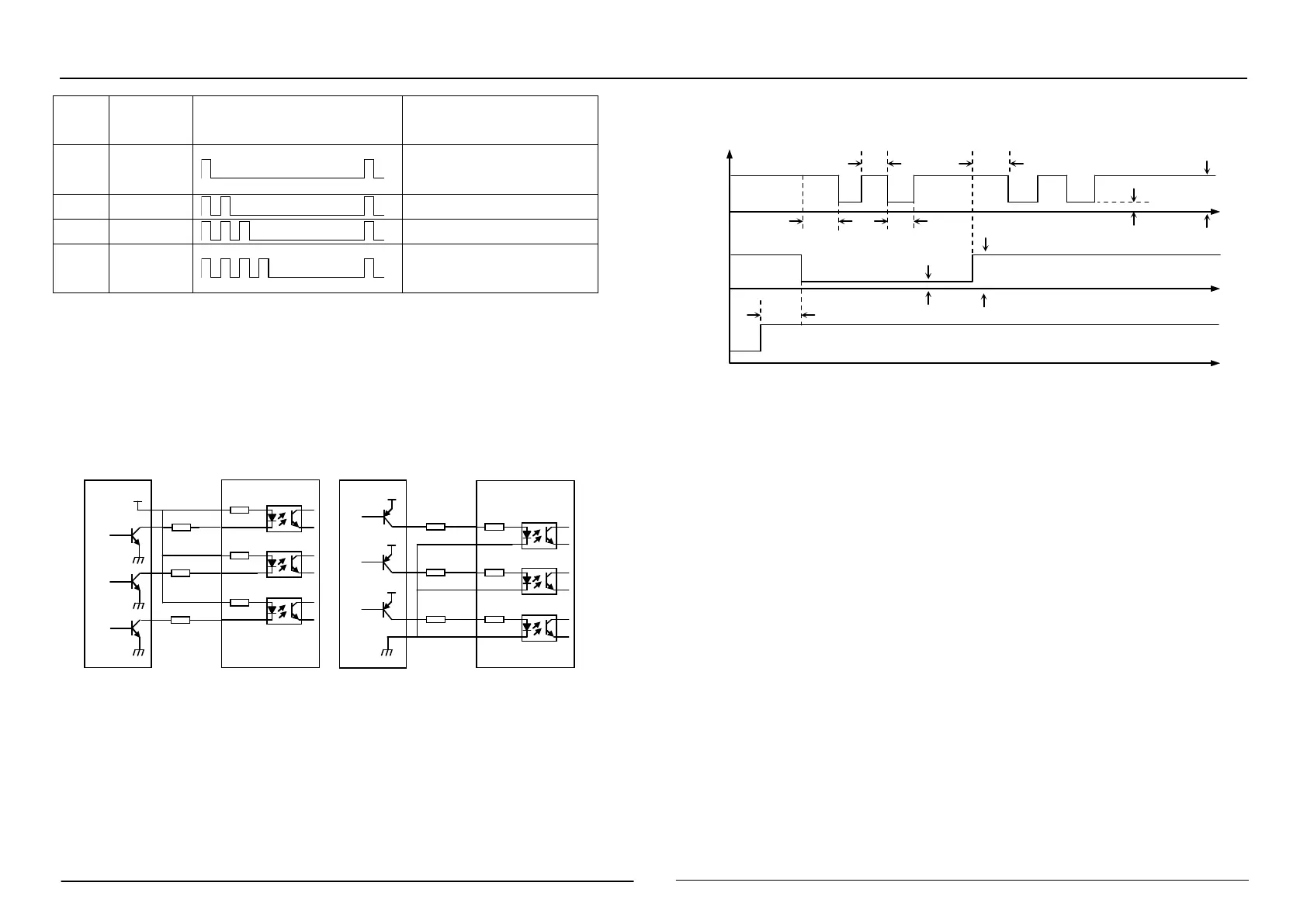

2. Control Signal Connector Interface

The DM542 driver uses a differential interface circuit for differential signaling, single-ended

common-cathode and single-ended common anode interfaces, and a built-in high-speed optocoupler

that accepts signals from long-line drivers, open collectors, and PNP output circuits. In the harsh

environment, we recommend long-line driver circuit, anti-interference ability. Now take the open

collector and PNP output as an example. The interface circuit is as follows:

Note: When the VCC value is 4.5~28Vdc, R is shorted or not connected;

3. Sequence Chart of Control Signals

In order to avoid some fault operations and deviations, PUL, DIR and ENA should abide by

some rules, shown as following diagram:

Remark:

a) t1: ENA must be ahead of DIR by at least 5

- are NC (not

connected). See “Connector P1 Configurations” for more information.

2)b)t2: DIR must be ahead of PUL effective edge by 2s to ensure correct direction;

3)c t3: Pulse width not less than 2s;

4)d)t4: Low level width not less than 2s.

4.

Control signal mode setting

Pulse Trigger Edge and Single and Double Pulse Selection: The pulse rising edge or falling edge

trigger is enabled by the PC software ProTuner software or STU debugger. It is also possible to set

the single pulse mode or the double pulse mode. In dual pulse mode, the signal from the direction

control must be held high or left floating.

5.

1)In order to prevent the driver from being disturbed, it is recommended to use the shielded cable

for the control signal, and the shield layer is shorted to the ground wire. Unless otherwise

specified, the shielded cable of the control signal cable is grounded at one end: the upper end of

the shielded cable is grounded at one end, and the shielded cable is driven. One end is suspended.

Only the grounding at the same point is allowed in the same machine. If it is not a real grounding

wire, the interference may be serious. At this time, the shielding layer is not connected.

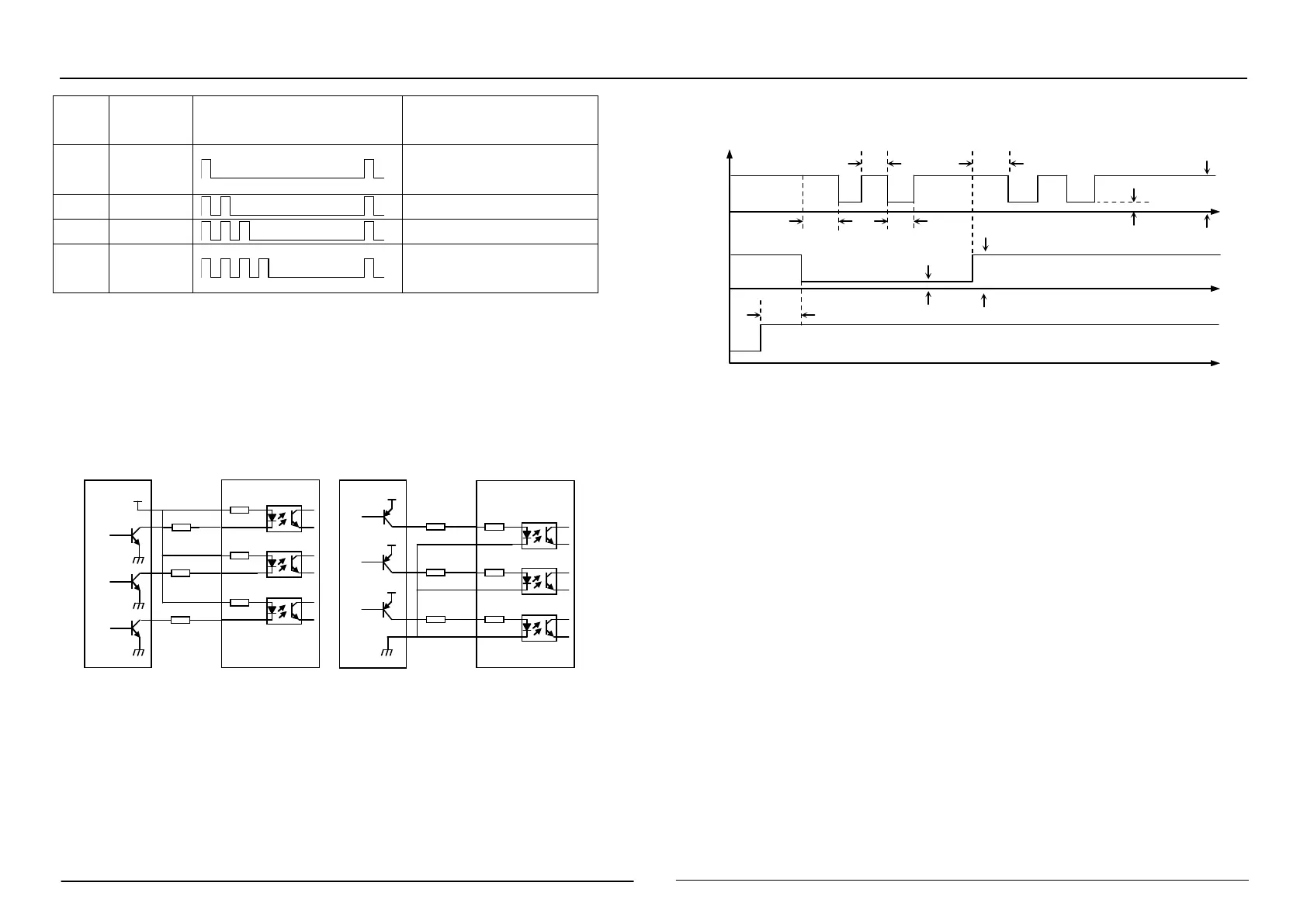

NO. number of

flashes

Red LED flashing waveform Fault description

1 1

Overcurrent or phase-to-phase

short circuit fault

2 2

Overvoltage fault

3 3

No definition

4 4

Open motor or poor contact

failure

Connections to open-collector

signal (common-anode) (common-cathode)

2

us

2us

High level>3.5V

igh level>3.5V

ow level<0.5V

ow lever<0.5V

Figure 4 control signal timing diagram

Loading...

Loading...