Fuel Pressurizing and

Drain Valve

The pressurizing valve includes a sliding

spring-loaded piston and a Teflon seat. A means

is provided to bring centrifugal pump pres-

sure to the backside of the piston so that valve

opening is a function of fuel pressure plus

spring force. Simultaneously, fuel is discharged

to the left and right manifolds. The drain valve

is a spring-loaded piston-type valve, which is

spring-loaded to the open position and is closed

by fuel pressure (60–100 psi).

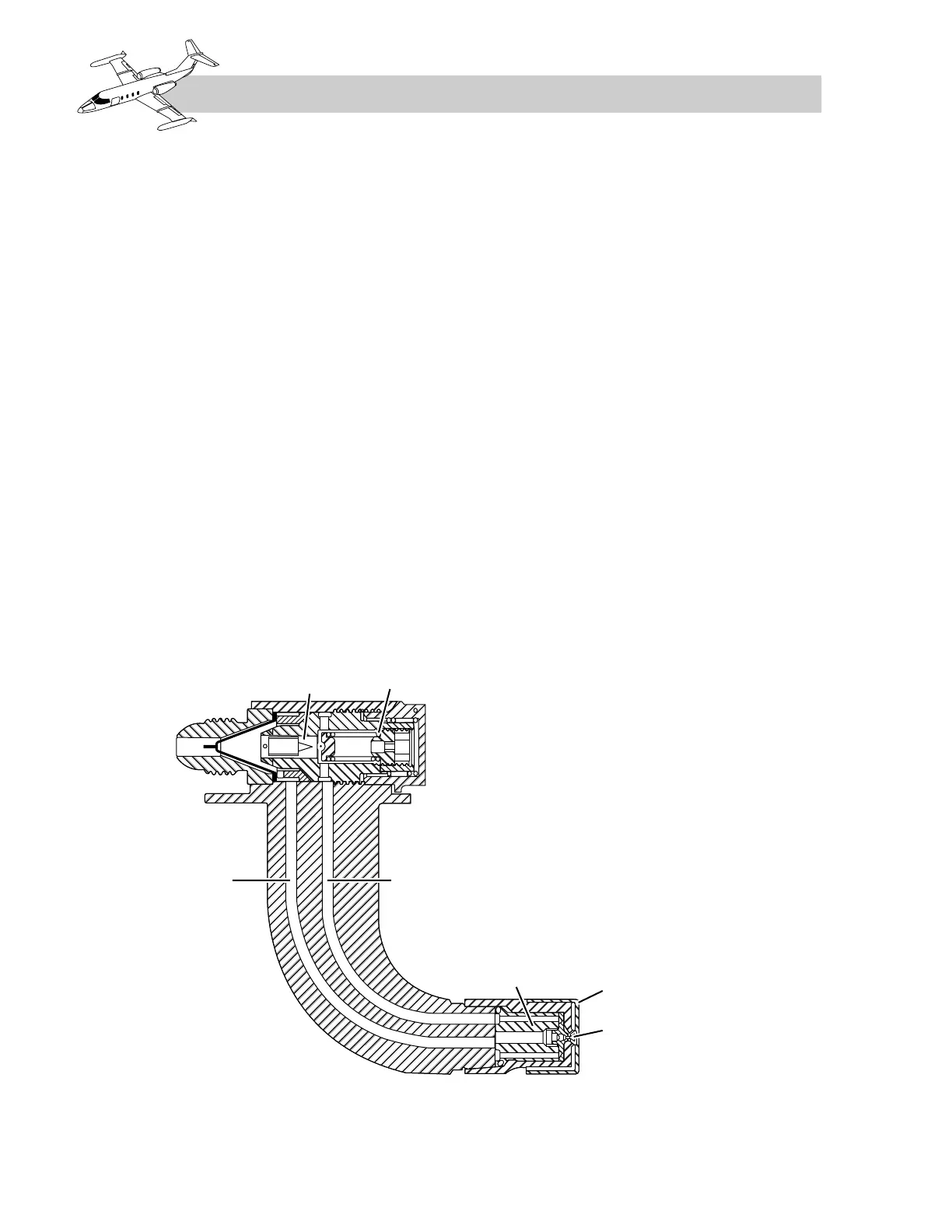

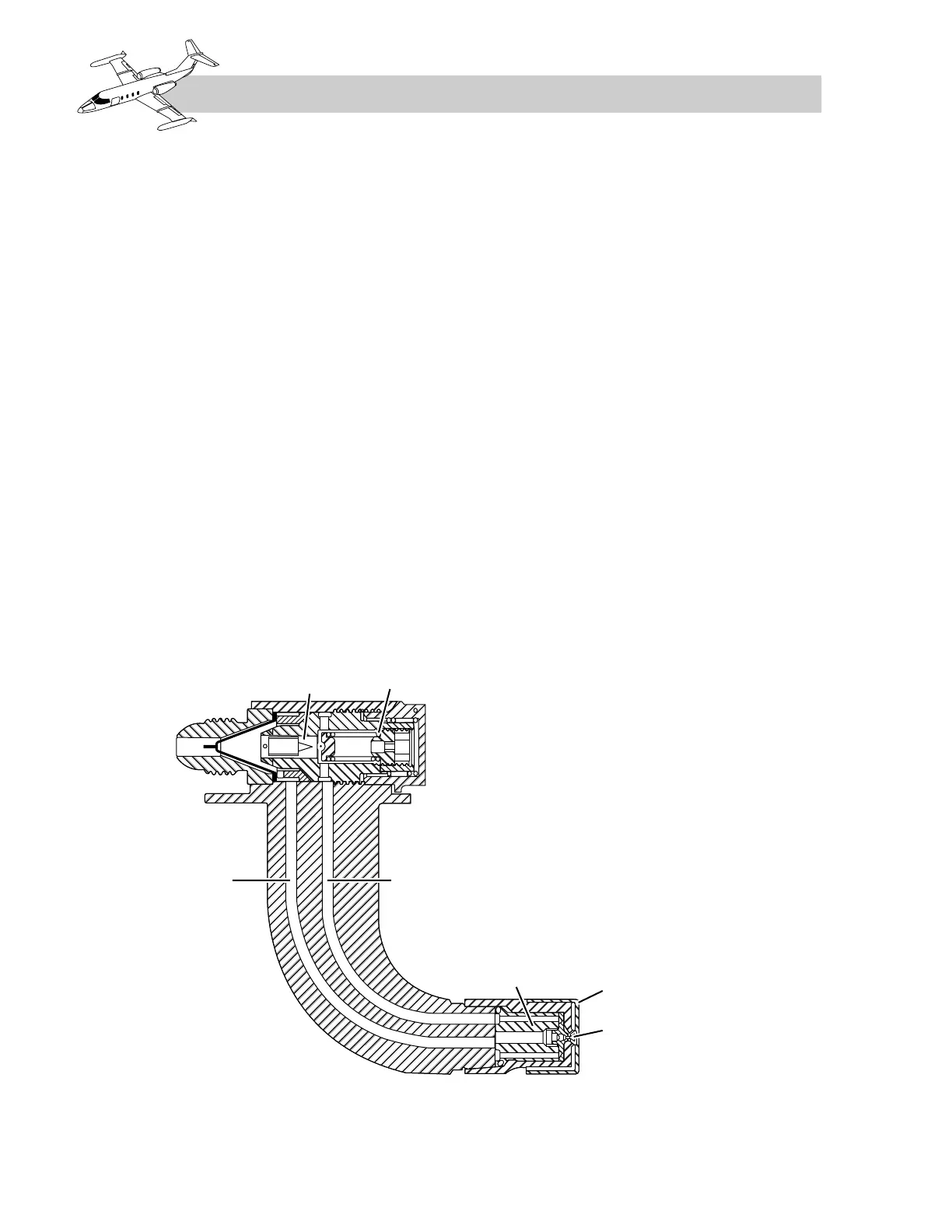

Fuel Nozzles

Twelve fuel nozzles provide the correct spray

pattern of metered fuel to the combustion sec-

tion for the entire operating range of the en-

gine. Each fuel nozzle has two major

sections—the flow divider and the nozzle

(Figure 7-10). The flow divider housings are

attached to pads on the mainframe which re-

tain the nozzles in position in the combustion

section. This housing has a fuel inlet port

which is connected to the fuel manifold, and

two outlet ports which supply fuel to the noz-

zle section through two tubes—the primary and

secondary fuel nozzles tubes. The air-cooled

nozzles section contains a primary and second-

ary orifice. The initial flow of fuel into the fuel

nozzle passes through the divider housing and

the primary fuel tube to the primary nozzle ori-

fice where the spray pattern is formed for

combustion.

As fuel pressure increases, fuel is allowed to

flow through the secondary fuel tube and noz-

zle orifice as well as the primary, forming an-

other spray pattern to supplement the fuel

requirements. During engine operation, the

primary flow remains constant, and the sec-

ondary spray flow increases to satisfy engine

operating requirements.

Fuel Drain Collector

A collector tank is installed to collect and re-

tain the fuel drained from the fuel manifold and

flow dividers through the drain section of the

pressurizing and drain valve during engine

shutdown. The canister volume is sufficient to

Loading...

Loading...