The system should be off below 70% rpm.

The indicator light will light if the system is

inadvertently left on with the landing gear

down. The control box senses pulse differ-

ence from the pickups, then energizes the

throttle cable actuator on the right (slave) en-

gine. The right engine rpm is matched to the

left (master) engine. The actuator travel is

limited; hence, the engines must be nearly

synchronized manually before setting the

control switch to ON to obtain maximum

±slave engine adjustment in synchroniza-

tion. The system operates on 28 VDC sup-

plied through a 7.5-amp circuit breaker

labeled “ENG SYN” on the copilot’s circuit-

breaker panel.

SYNCHROSCOPE (OPTIONAL)

Manual engine synchronization can be moni-

tored with the dual-engine synchroscope. The

synchroscope is basically a synchronous motor

driven by outputs from the tach generators and

is otherwise independent of the airplane electri-

cal system. A wheel marked by black and white

sections moves clockwise or counterclockwise

at a rate proportional to the difference in fre-

quency of the tach generators. Clockwise rota-

tion is for the right tach fast, and counterclock-

wise is for the left tach fast. Synchronization is

accomplished by adjusting either engine thrust

lever until the wheel stops rotation.

THRUST REVERSERS

(OPTIONAL)

GENERAL

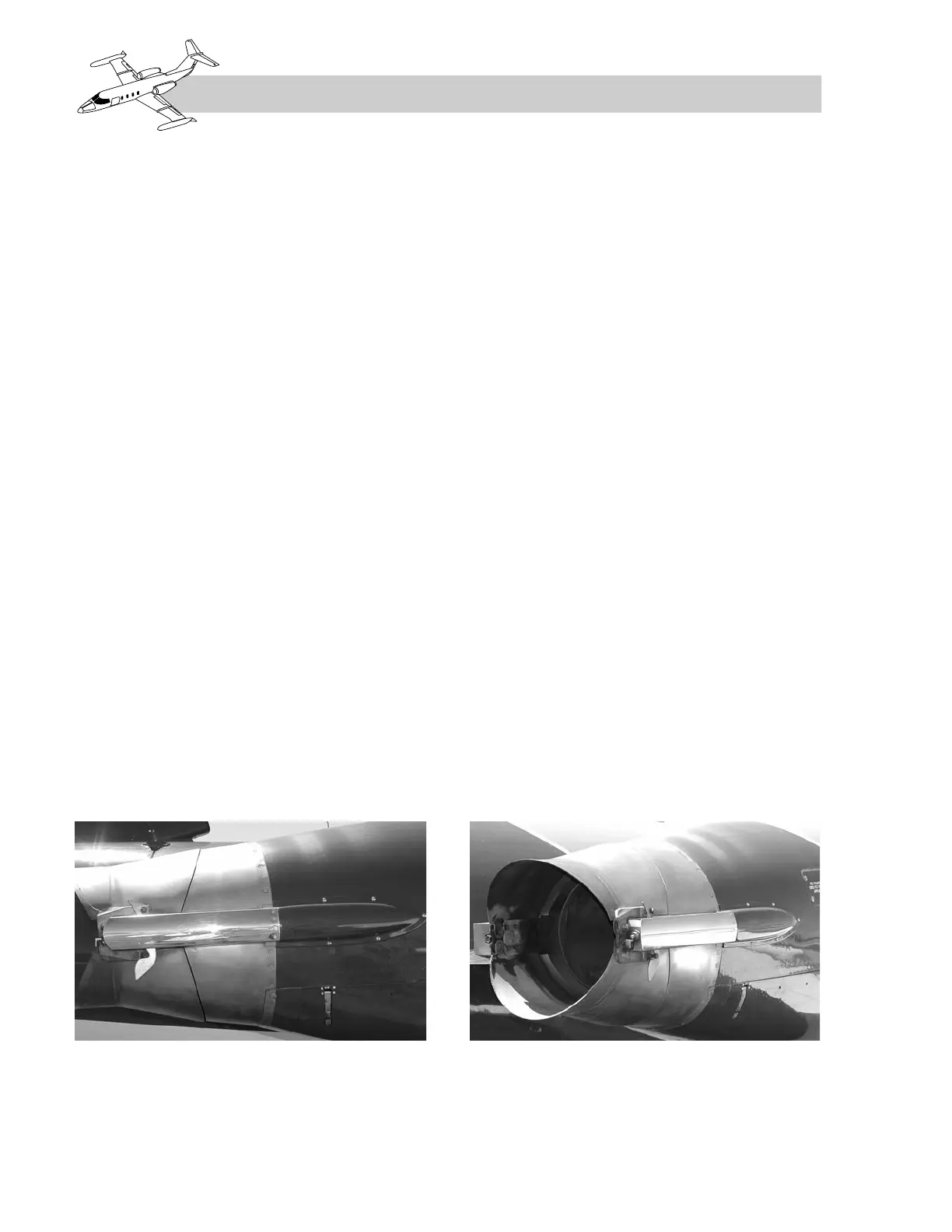

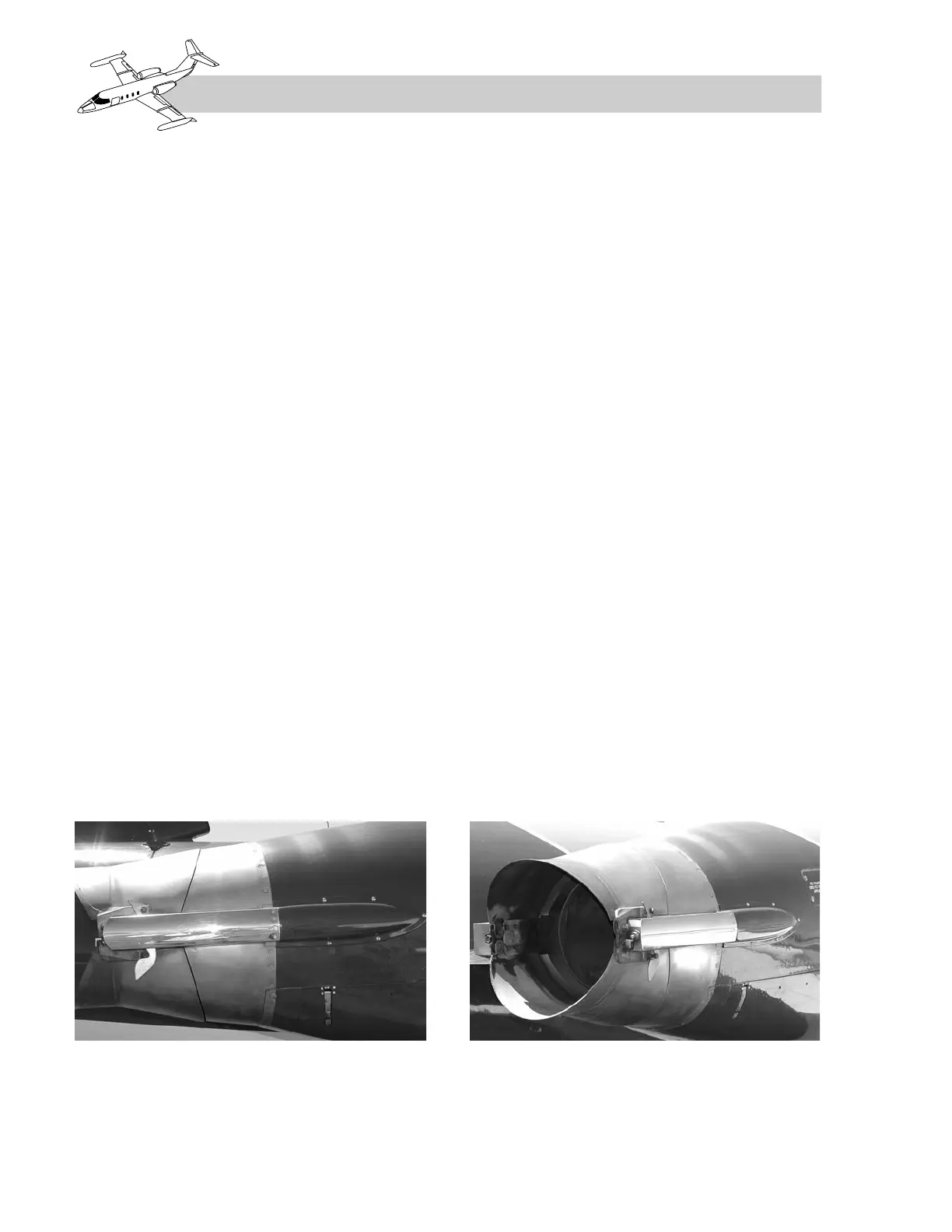

The thrust reversers (Figure 7-15) are an ad-

ditional deceleration system which may be

used anytime the airplane is on the ground

to produce shorter stopping distances. They

cannot be used to supersede runway length

requirements published in the performance

chapter of the AFM.

Each engine is equipped with a target thrust

reverser (T/R) consisting of upper and lower

clamshell doors (buckets), pivoted near the

engine centerline. The reverser doors are hy-

draulically actuated, and electrically con-

trolled mechanical latches are provided for

each engine to secure the doors in the stowed

position. Hydraulic pressure for the system is

supplied by the airplane hydraulic system

through a one-way check valve. The T/R sys-

tem includes an accumulator. When fully

charged, the accumulator hydraulically pro-

vides several cycles should the airplane hy-

draulic system fail upstream of the one-way

check valve. The accumulator is serviced to

650 psi with dry air or nitrogen (hydraulic

pressure zero).

Figure 7-15. Thrust Reversers

Loading...

Loading...