LEGA

LEGA LEGA

LEGA

srl

srlsrl

srl

C

CC

Costruzioni

ostruzioni ostruzioni

ostruzioni A

AA

Apistiche

pistichepistiche

pistiche

–

––

–

via Maestri del Lavoro 23

via Maestri del Lavoro 23 via Maestri del Lavoro 23

via Maestri del Lavoro 23 –

––

–

48018 Faenza

48018 Faenza48018 Faenza

48018 Faenza

www.legaitaly.com

www.legaitaly.com www.legaitaly.com

www.legaitaly.com -

--

-

Tel 054626834

Tel 054626834 Tel 054626834

Tel 054626834 –

––

–

Fax 054628279

Fax 054628279 Fax 054628279

Fax 054628279 –

––

–

P.iva 00043230390

P.iva 00043230390P.iva 00043230390

P.iva 00043230390

11 / 40

1.0

1.01.0

1.0

GENERAL SAFETY DIRECTIONS

GENERAL SAFETY DIRECTIONSGENERAL SAFETY DIRECTIONS

GENERAL SAFETY DIRECTIONS

READ THIS MANUAL THROUGHOUT BEFORE USING THE MACHINE

This handbook forms an integral part of the machine and should be kept with it throughout its working life.

The machine includes dangerous electrically live and moving parts, which can cause serious damages to

persons or property in case of:

-

incorrect use

-

removal of guards or disconnection of safety devices

-

poor inspection and servicing

-

tampering with the electric system

These directions must be completed and updated according to applicable legal provisions and technical safety

standards.

The manufacturer may not be held responsible for failures, breaks or accidents resulting from incorrect use

The manufacturer may not be held responsible for failures, breaks or accidents resulting from incorrect use The manufacturer may not be held responsible for failures, breaks or accidents resulting from incorrect use

The manufacturer may not be held responsible for failures, breaks or accidents resulting from incorrect use

of the machine or failure to follow the direct

of the machine or failure to follow the directof the machine or failure to follow the direct

of the machine or failure to follow the directions contained in this manual.

ions contained in this manual.ions contained in this manual.

ions contained in this manual.

1.1

1.11.1

1.1

IDENTIFICATION OF THE MACHINE

IDENTIFICATION OF THE MACHINEIDENTIFICATION OF THE MACHINE

IDENTIFICATION OF THE MACHINE

Uncapping machine designed for cutting off the cappings on D.B. standard and Langstroth frames (also

referred to as super frames/supers) with or without Hoffmann spacer, using electrically heated serrated knives

on a chain conveyor.

1.2

1.21.2

1.2

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

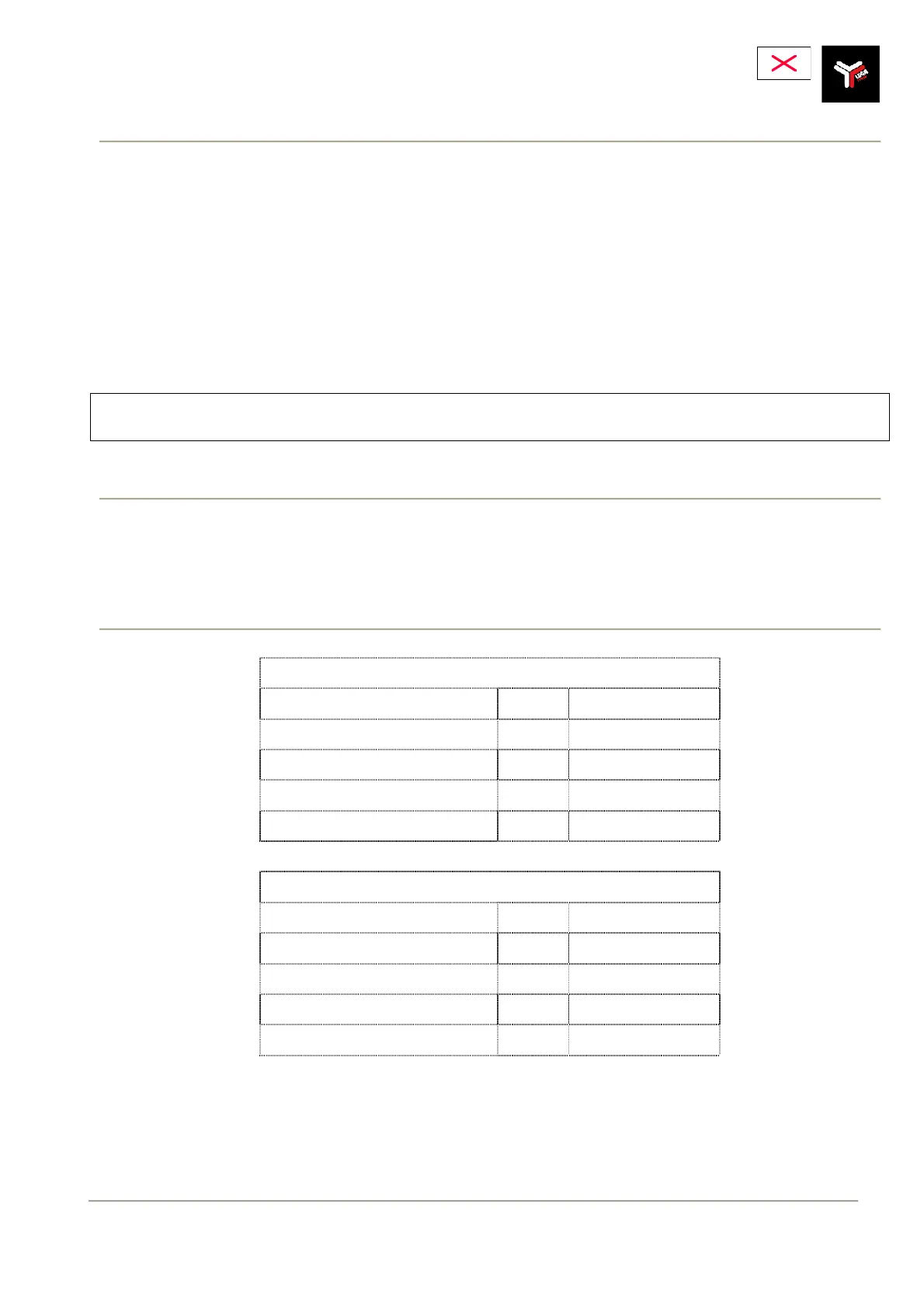

Art. 4350 Uncapping machine DV2 D.B.

Art. 4350 Uncapping machine DV2 D.B.Art. 4350 Uncapping machine DV2 D.B.

Art. 4350 Uncapping machine DV2 D.B.

Uncapped frames Nr / H 480

Total Absorption Kw 1800

Input voltage V 220

Weight Kg 49

Overall dimensions (WxDxH) mm 860x660x600

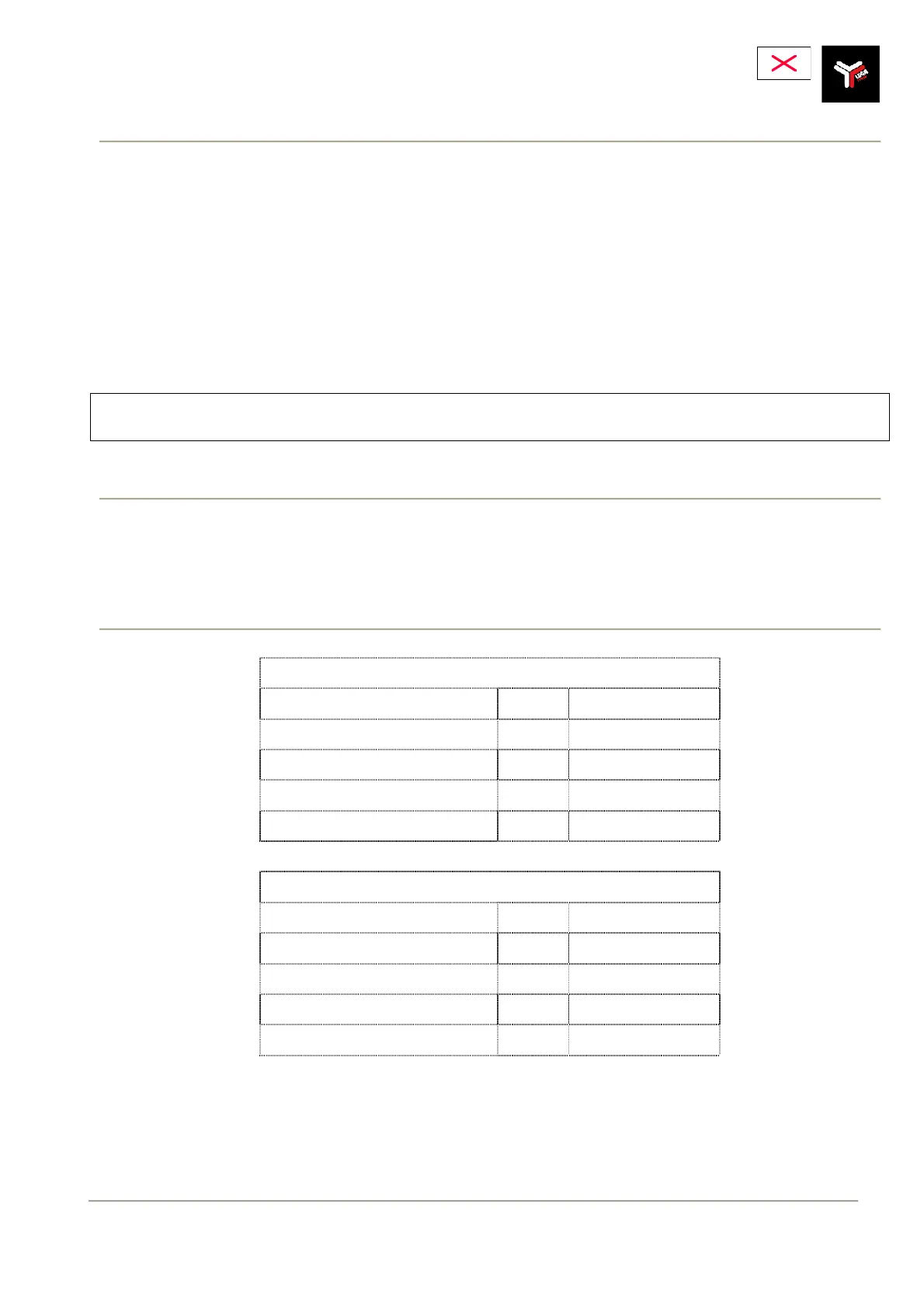

Art. 4351 Uncapp

Art. 4351 UncappArt. 4351 Uncapp

Art. 4351 Uncapping machine DV2 Langstroth

ing machine DV2 Langstrothing machine DV2 Langstroth

ing machine DV2 Langstroth

Uncapped frames Nr / H 360

Total Absorption Kw 1800

Input voltage V 220

Weight Kg 49

Overall dimensions mm 860x660x600

Loading...

Loading...