27

Chapter 4Frame Mortise & Tenon Jig User Guide

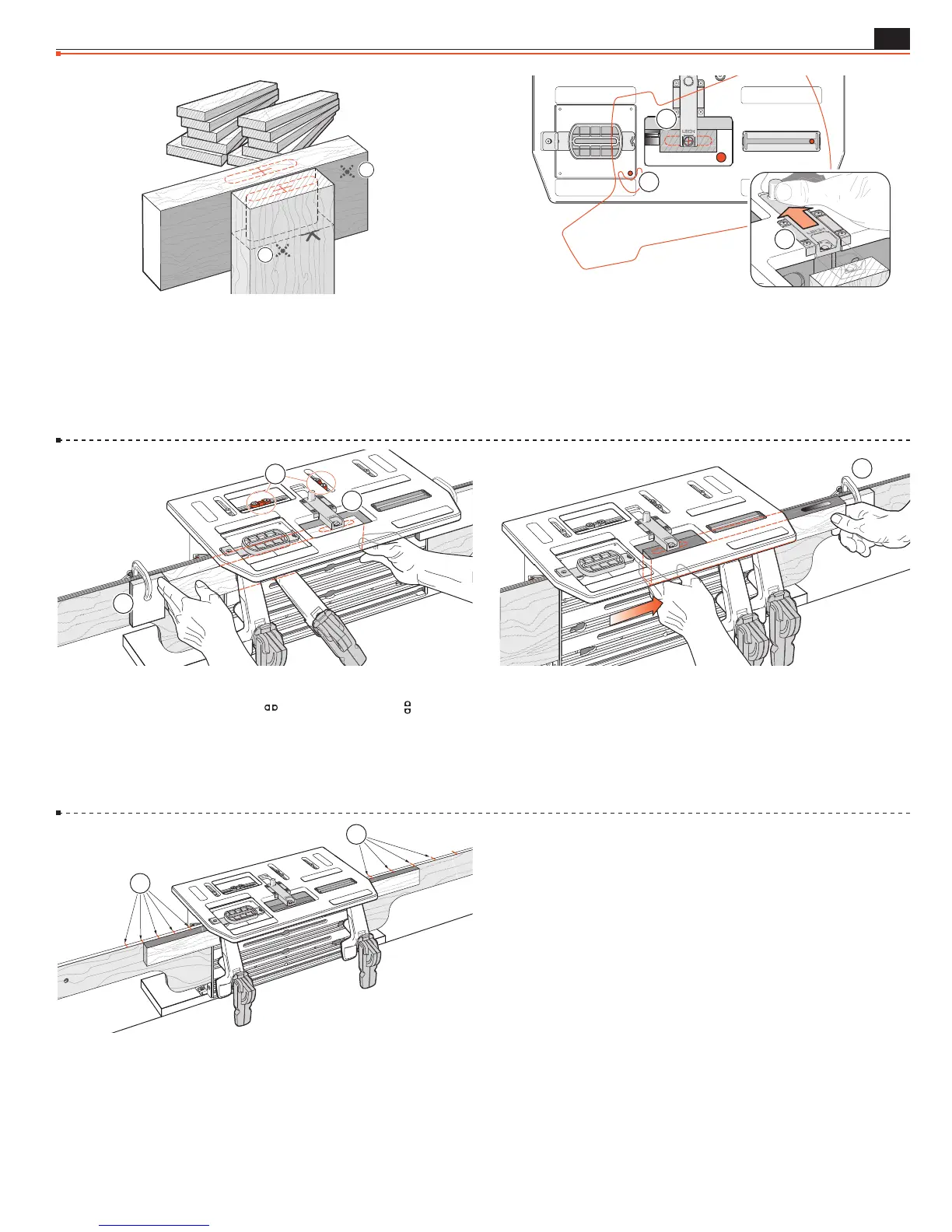

4-27 Production Procedures When routing frame joints it

is only necessary to mark and sight a single tenon and perhaps two

mortises. Once the side stop fence or outriggers are set and the table

sighted for one joint, any number of similar joints may be routed

without marking and without removing the router from the jig.

We recommend marking the finished face which goes against the

clamp plate (shown here from operator view)

➀

.

1

1

4-28 Tenons The router is “parked” with the guide pin in near

front corner of recess

➀

. Extend sight and use only as a tenon stop

➁

when

clamping successive (unmarked) tenon pieces against side stop. Retract

sight

➂

and rout any number of tenons without removing router. Note:

If you forget to retract the sight, the Sub-Base will push it out of the

way as you move it rearward, but we do not recommend this.

3

1

2

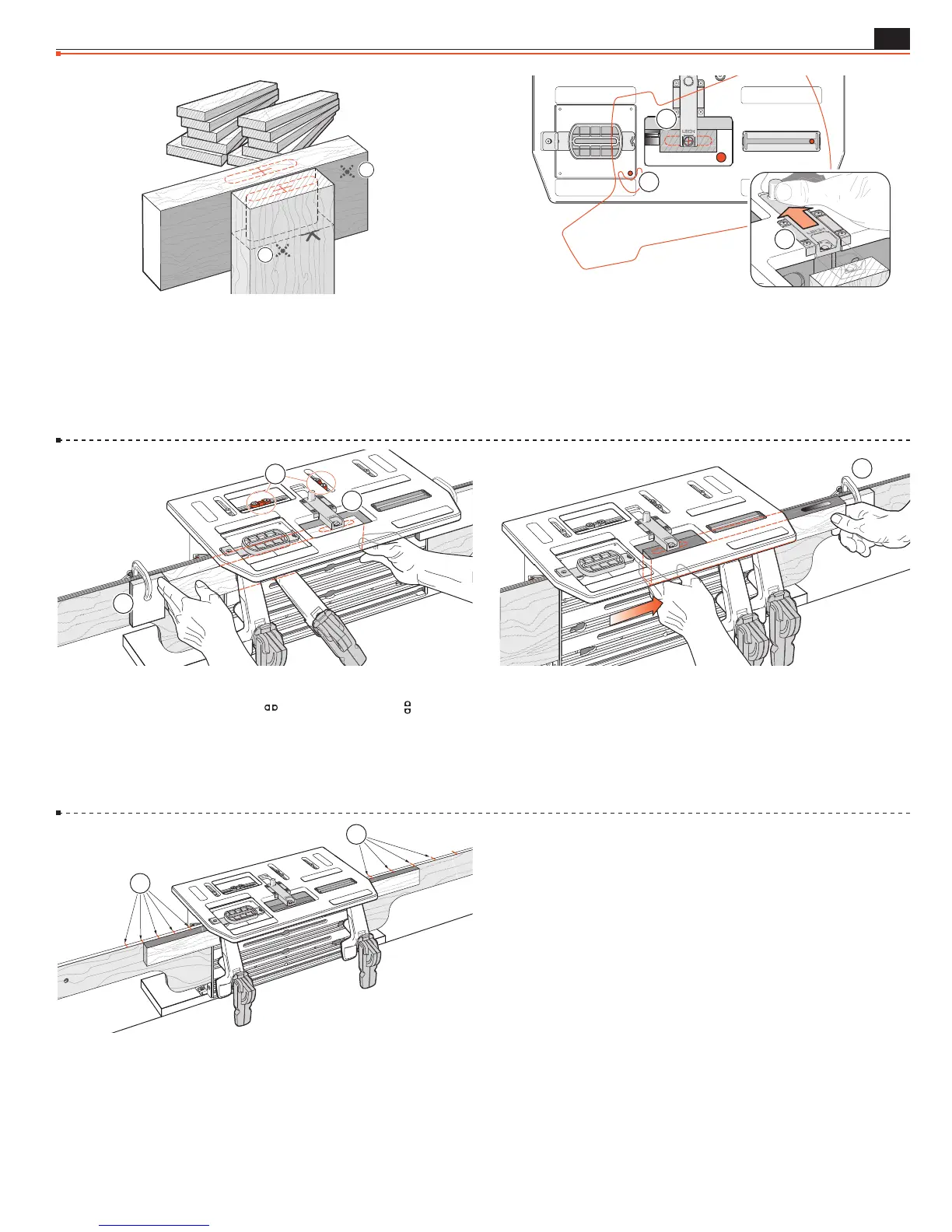

4-29 Mortises: Sight one mortise

➀

and set a stop block at the

end of the mortise board

➁

. Set

limit stops and

limit

stops to prevent unintentional table movement

➂

.

2

1

3

4-30 Sight the second mortise by moving the mortise piece (not

the table) and set the second stop block

➁

.

Rout any number of successive (unmarked) mortises without

removing the router from the table.

2

4-31 Successive mortises in “ladder” type construction are quick to

rout. Mark all mortises on only one piece (only one needs a front-to-

back mark!). Sight the first mortise (cross) to set the table and mark

the top of one outrigger in line with the workpiece end. Table locked,

move the workpiece, sighting each successive mortise line, marking

the outrigger(s). To rout, align the unmarked board ends with the

outrigger marks

➀

.

■

See next page for Production routing of Small Joints.

1

1

Production Procedures

MORTISE & TENON ROUTING PROCEDURES

Loading...

Loading...