FMT PRO CHAPTER 4

MORTISE & TENON ROUTING PROCEDURES

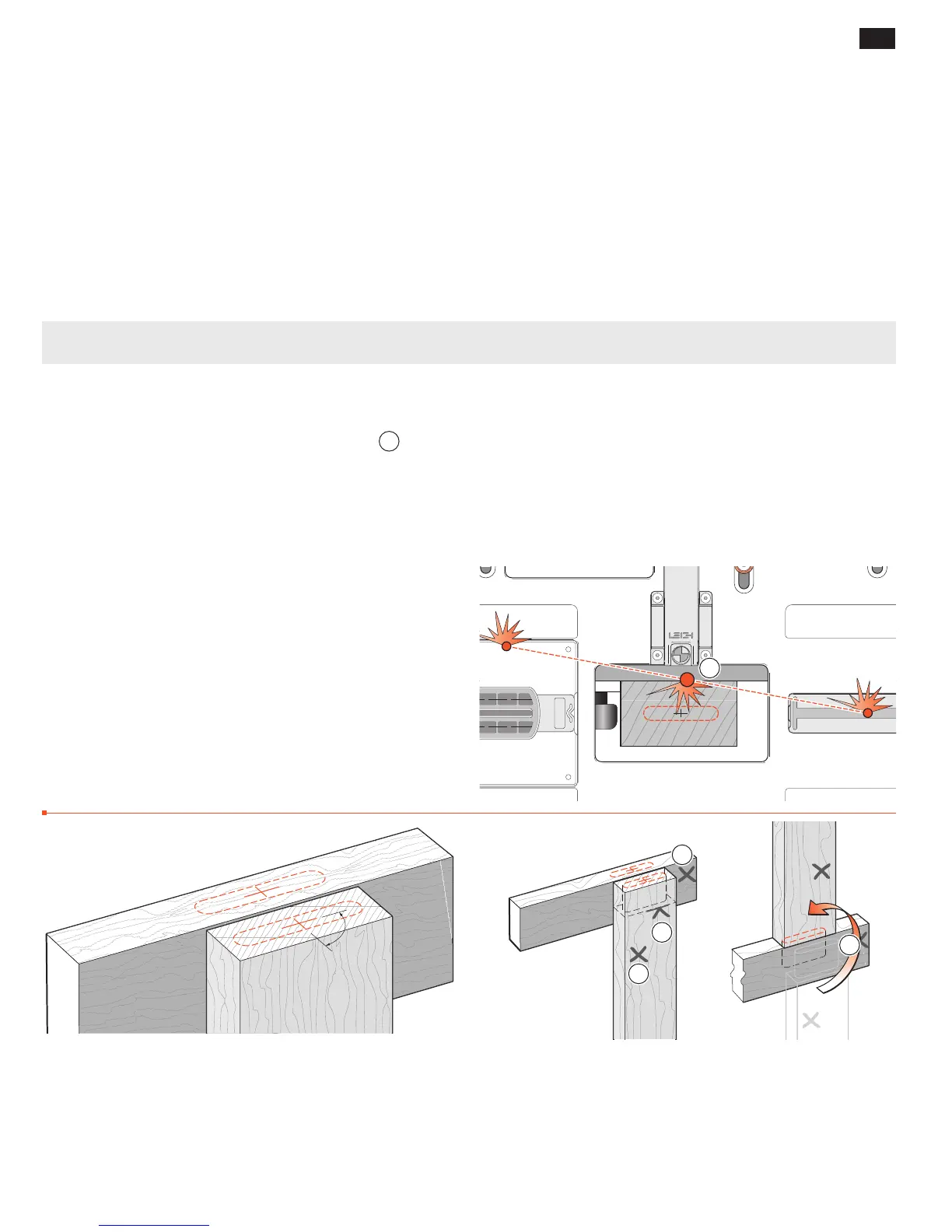

4-1 Let’s make a plain single mortise and tenon. Using a fine pencil,

mark a cross at the center of the required tenon and mortise. The

cross lines along and across the axis lines of the joint must be at

90˚ to each other. Mark the mortise several inches[10cm] or so

away from the end.

90˚

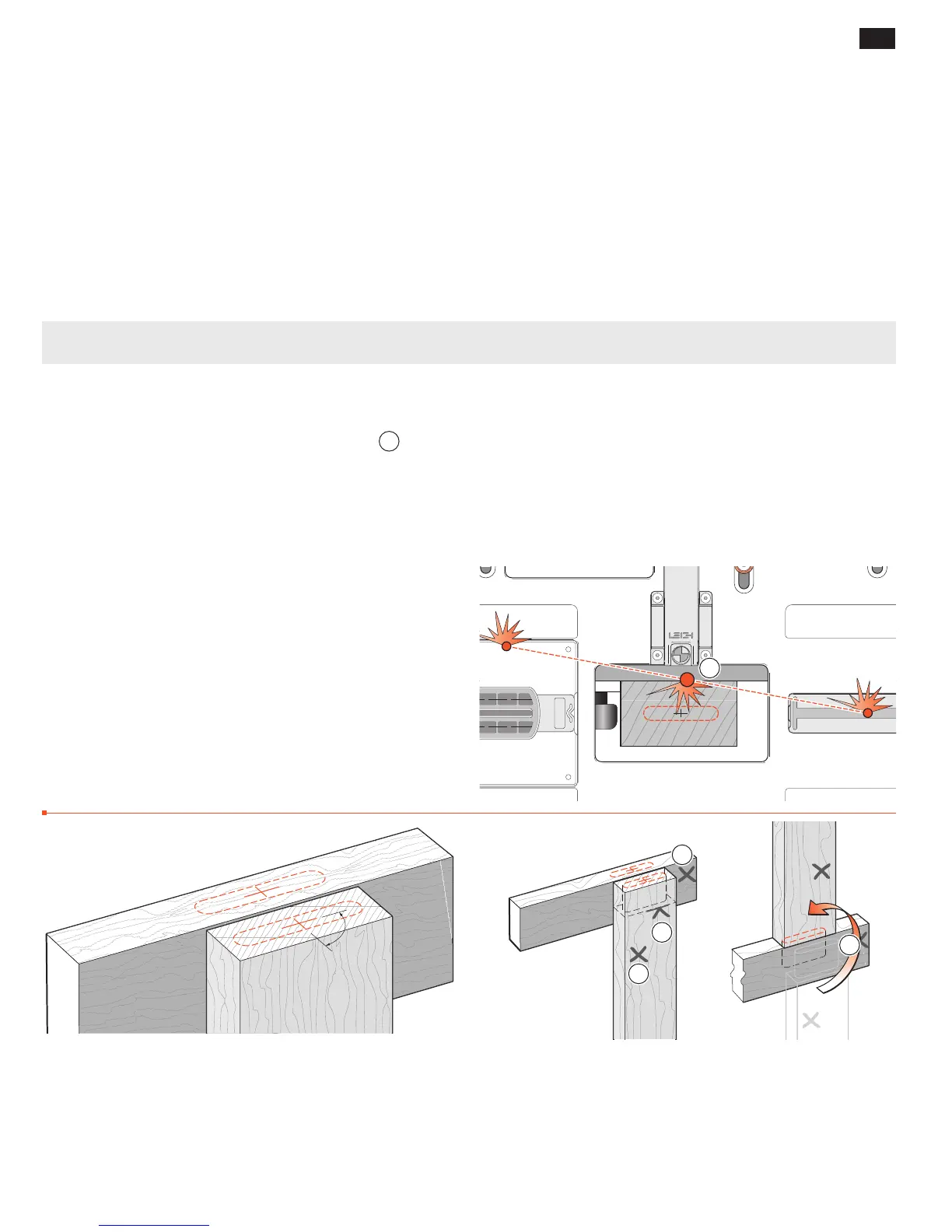

4-2 In almost all cases, it is critical to have the same side of

workpieces reference against the clamp plate for each tenon and

mortise. So mark one side of each workpiece to reference “this side

toward the clamp plate”

➀

, or “away from” if you prefer. Make a pencil

mark

➁

to the required shoulder depth on the tenon workpiece. When

the joint is cut, the tenon piece is rotated 180˚ to assemble

➂

.

1

2

1

3

Single Mortise & Tenon, Test

1

Mortise & Tenon

Routing Procedures

21

Single Mortise & Tenon, Test

Production Procedures

Production Procedures for Small Joints

Routing Joints Smaller than 1/4"

m IMPORTANT SAFETY NOTE

Take great care to not “trap” the bit against the side of tenon

rails

➀

. Do not attempt to rout center tenons in rails thicker than

1

5

/16"[34mm] before referring to 5-39 through 5-44.

Without using the table movement as prescribed, the bit would

have to be plunged into the side of the tenon rail causing the bit

to powerfully “drive” the router across the jig. This could be

dangerous and can damage the jig.

Before using your Leigh FMT Pro you must

have completed all of the preparatory

steps including reading the router safety

recommendations on the previous pages.

If you haven’t done so, it is essential that

you do it now.

See Appendix I for complete joint specifications and guide and bit selection

D

Loading...

Loading...