62

Appendix II Frame Mortise & Tenon Jig User Guide

JIG ADJUSTMENTS

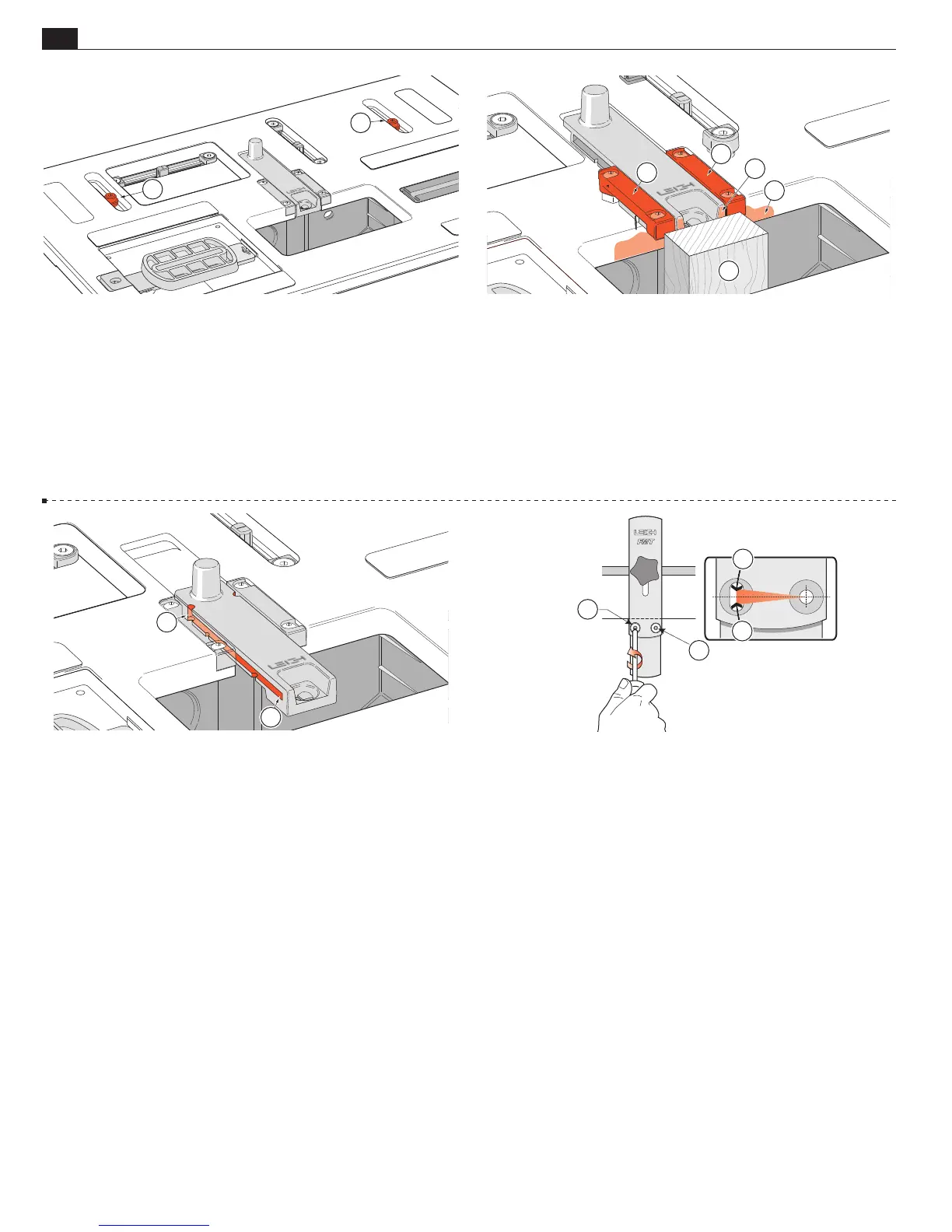

A2-5 Table Clamp Setting

The setting for this is factory pre-set

using a torque tool. Should you need to adjust the pressure, lock

the table and lightly tighten the two clamp screws equally

➀

. Do

not adjust these screws with the table unlocked. You should be

able to work the table lock lever with quite light pressure. When

locked, it should not be possible to move the table with firm side

to side hand and arm pressure. When unlocked, it should be easy

to position the table without sticking. The screws are treated with

Loctite™ to prevent accidental rotation.

1

1

A2-6 Sight Position

The sight position is factory set. If you

ever need to reset it here’s how. Clamp a straight vertical rail that

projects through the table bit opening

➀

. Slightly loosen the

four small hex cap screws that hold the two sight rails

➁

using

the provided hex key. Move the table forward until the rear edge

of the bit opening

➂

firmly touches the vertical rail

➀

, and lock

the table. Pull the sight and rails against the wood piece

➃

; at the

same time centring the rear end of the sight in the recess. Tighten

the four screws.

2

3

4

2

1

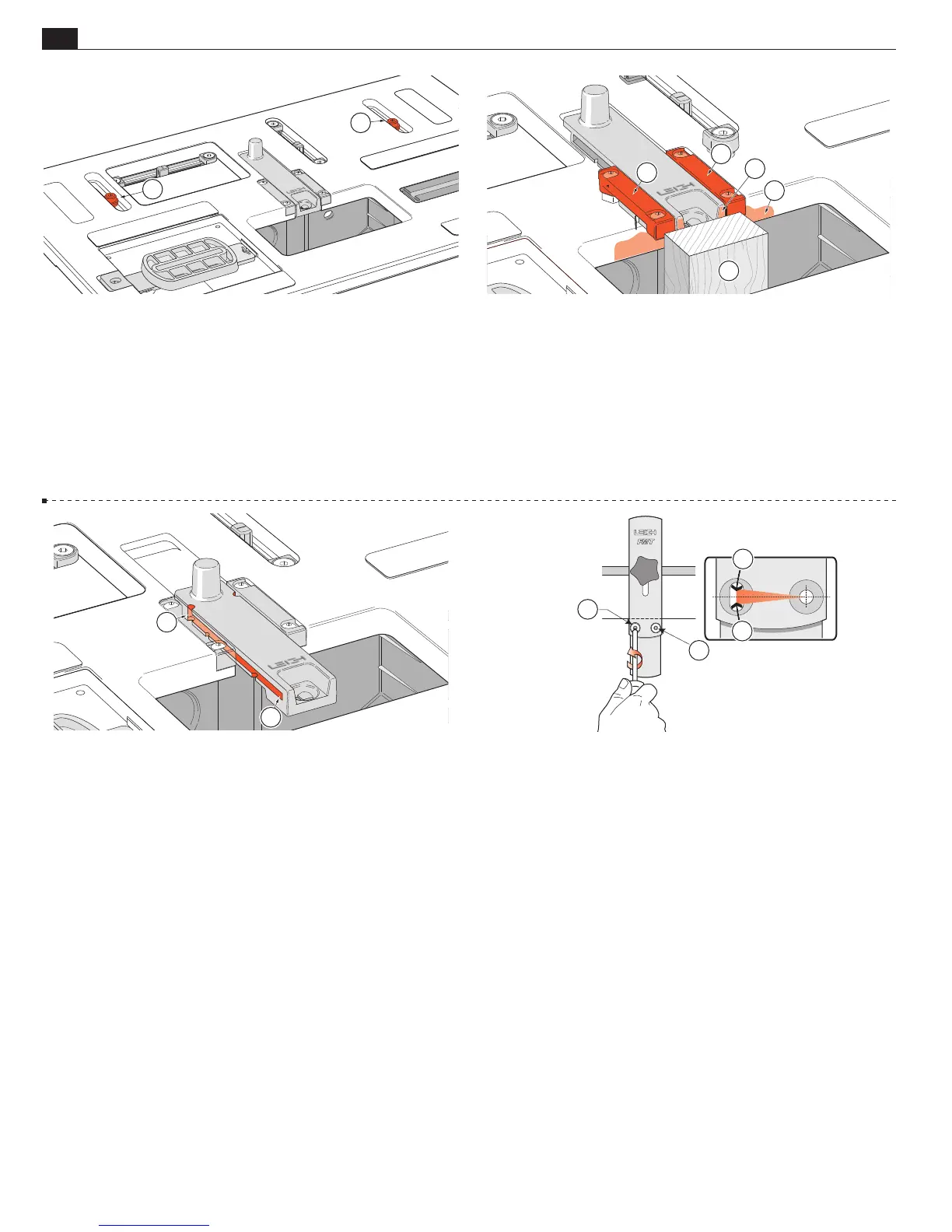

A2-7 Jig Maintenance

Very little maintenance is required. Fine

dust build-up in the front and rear sight stops should be removed

from time to time. The end of the small hex key or a piece of wire

will do the trick. At the front

➀

and with the sight to the rear

position at

➁

. Dusting off with compressed air (if available) will

keep the jig clean.

1

2

A2-8 The sidestop fence is squared at the factory, but check your first

test joints. If your router/bit is not perfectly perpendicular to the table

adjust the sidestop fence: slightly loosen the 'pivot' screw

➀

and the 'lock'

screw

➁

. Adjust the angle

➂

to match the bit and retighten. Rout test

joints to confirm correct setting. Once locked in this position it should

never need adjusting when used with that same router.

■

1

2

3

3

Loading...

Loading...