4

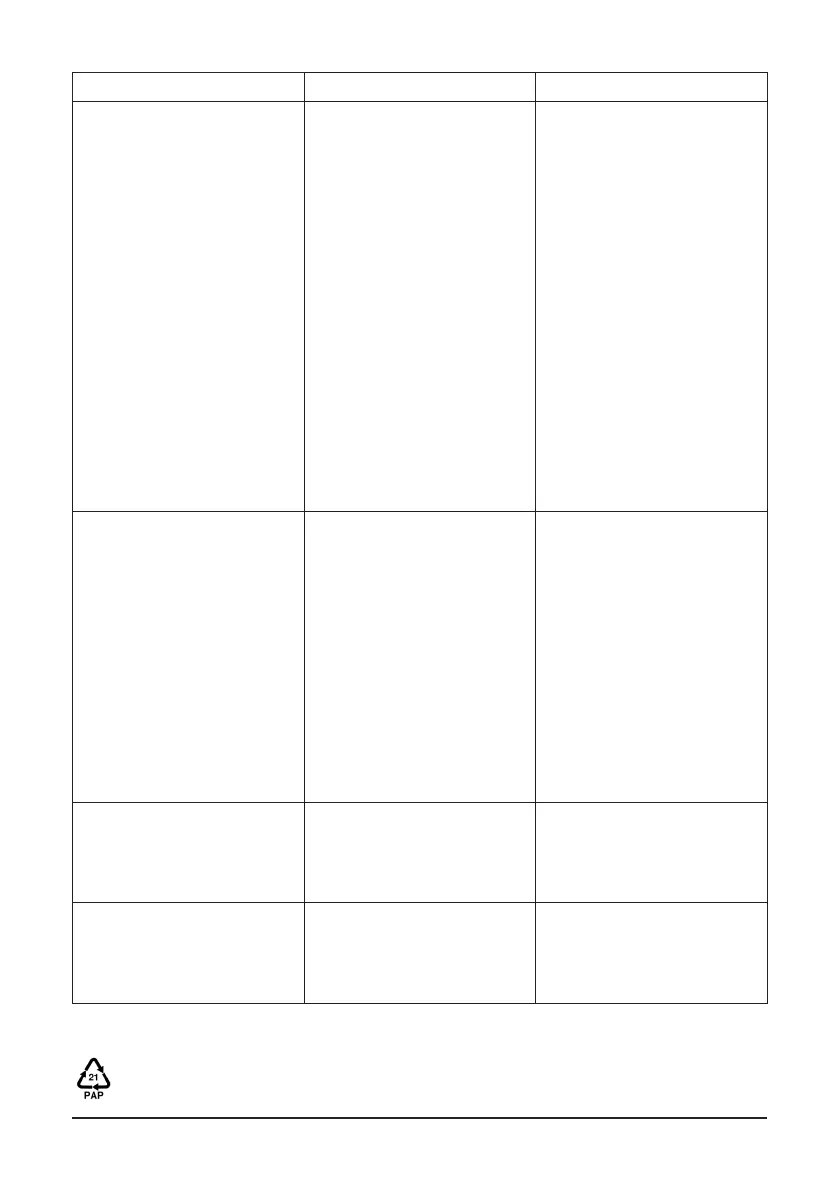

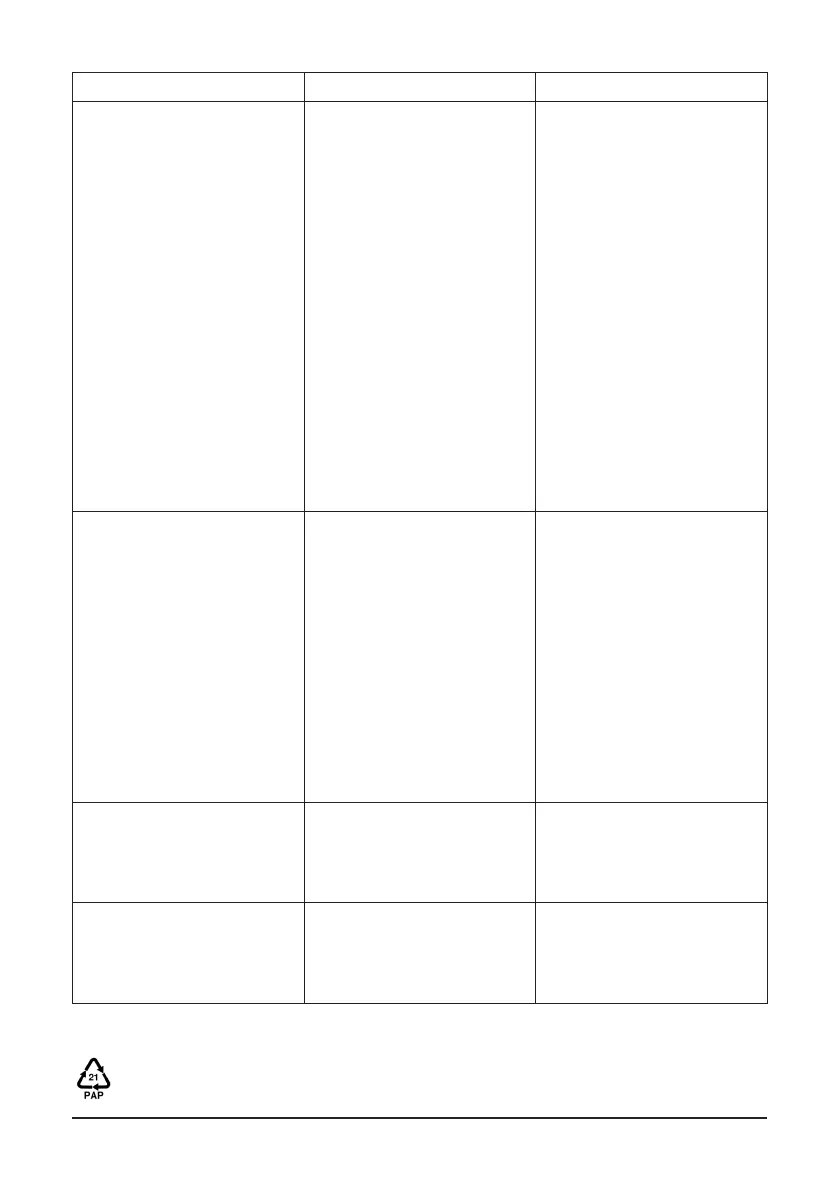

Problem Cause Solution

During lamination the

pouch gets stuck in the

front part of the laminator.

Glue deposits on the

roller / heat reaction of

pouch.

Press reverse button as

soon as possible. The

pouch is driven out through

the input tray. Assist the

process by carefully pulling

at the pouch. As soon as

the pouch has left the front

sensor area, ensure the

pouch is clear of the entry

area to prevent the pouch

from being pulled in again.

To laminate another item,

switch the device on again.

Clean the rollers after any

pouch jam as described in

section “Maintenance and

care”.

During lamination the user

switches off the device or

the mains power fails or

the device is otherwise

disconnected from mains.

Power failure. After re-starting the

laminator, automatic

reverse is activated for 30

seconds to drive out the

pouch through the input

tray. As soon as the On/Off

button lights blue, you can

laminate again as usual.

Clean the rollers after any

pouch jam as described in

section “Maintenance and

care”.

When pressing the

Reverse button, the pouch

is not being reversed but

transported further.

Normal behaviour because

the pouch has already

left the front part of the

laminator.

None.

The laminator always

runs at the same speed

regardless of the thickness

of the material.

Thickness sensor

defective.

Please let the laminator

be inspected by customer

service.

Disposal

The symbol on the packaging indicates that the packaging is made of

PA P.

Loading...

Loading...