74 WELGER RP 202 • RP 220 • RP 302 • RP 320

12.9. Lubrication chart

after every 500 bales (or daily)

Pos

(fig. 82)

Baler component Lubricant

(Table 4)

Remark

1 Universal drive shaft A

2 Chain lubrication B Right side of baler

3 Tailgate hinge1) A Both sides

4 Lubricating manifold*, left front

A

2)

Lubricating manifold*, right front

A

2)

not shown in fig. 82

5 Lubricating manifold*, left rear

A

2)

Lubricating manifold*, right rear

A

2)

not shown in fig. 82

6

Locking hook

1)

A Both sides

7 Locking roller A Both sides

8

Cutting rotor*

1)

A Both sides

9 Swivel wheels* A Both sides

10 Tailgate guide dome A On right side of baler: grease

11 Pick-up unit 2.00 m (SPECIAL):

• bearing of actuator (1x)

• bearing of rake shaft (2x)

• Sliding bearing of rake (2x)

A not shown in fig. 82

1)

depending on the fitted equipment, already served by central lubricating manifold

2)

Supply the lubricant distributor with 1 - 2 strokes from a hand lever grease gun – do not use a compressed

air grease gun.

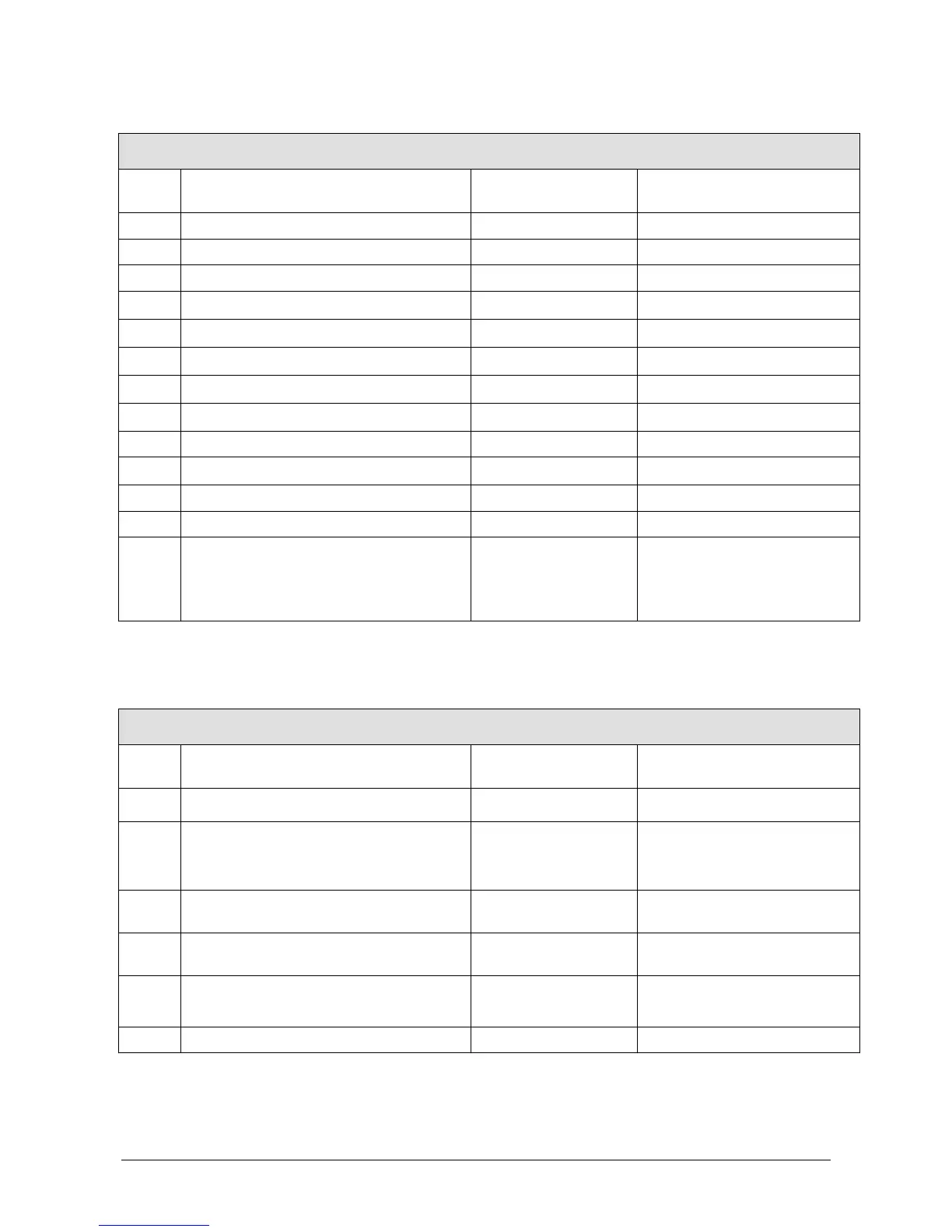

yearly after the end of season (weekly under extreme operating conditions)

Pos

(fig. 82)

Baler component Lubricant Remark

12 Star ratchet in the pick-up unit drive A

For 1.50 m pick-up, only

installed outside the EU

13 Main gearbox

• RP 202 / RP 302

• RP 220 / RP 320 ("V V")

3)

1.65 l SAE 90

2.0 l SAE 90

Oil change

Check oil level with dipstick or

overflow hole

14 Moveable parts of the net wrapping

system*

D Keep running smoothly

15 Moveable parts of the twine wrapping

system*

D Keep running smoothly

16 Locking hook disc spring E

Dismantle, clean and grease;

Warning: do not change sensor

settings!

17 Twine guide eyes A Lightly grease chafe mark

3)

Gearbox is labelled on the top side with the letters "V V"

Loading...

Loading...