2

INTRODUCTION

We appreciate your decision to purchase a LEMMER product. With proper maintenance (as

outlined in this manual) you will be assured years of excellent results. For prompt and courteous

service or advice, please contact any of our factory outlets which are listed on page 15.

SPRAY GUN OPERATION

LEMMER Electric Airless Spray Guns operate with a high pressure piston action pump, which

creates the pressure needed to finely atomize all sprayable materials. The piston movement is

obtained through the use of a 120 V, 60c/s oscillating motor. The resulting 120 piston strokes per

second are combined with a durable one-way valve to draw in paint, pressurize the paint, and

spray it out in a finely atomized mist. Since the mist is airless (no air used to convey the paint),

very little overspray is produced. The results are smooth finishes, minimal paint loss, and very easy

clean-up. Since many of today's paints have abrasive qualities, the LEMMER guns have been

specially designed to handle these tough paints. Extensive use of ceramics, and a specially

grooved tungsten carbide piston, make these airless spray guns extremely durable. Ceramics have

the advantage of being harder than tungsten carbide, as well as having very low friction values,

resulting in much less wear when compared to conventional materials.

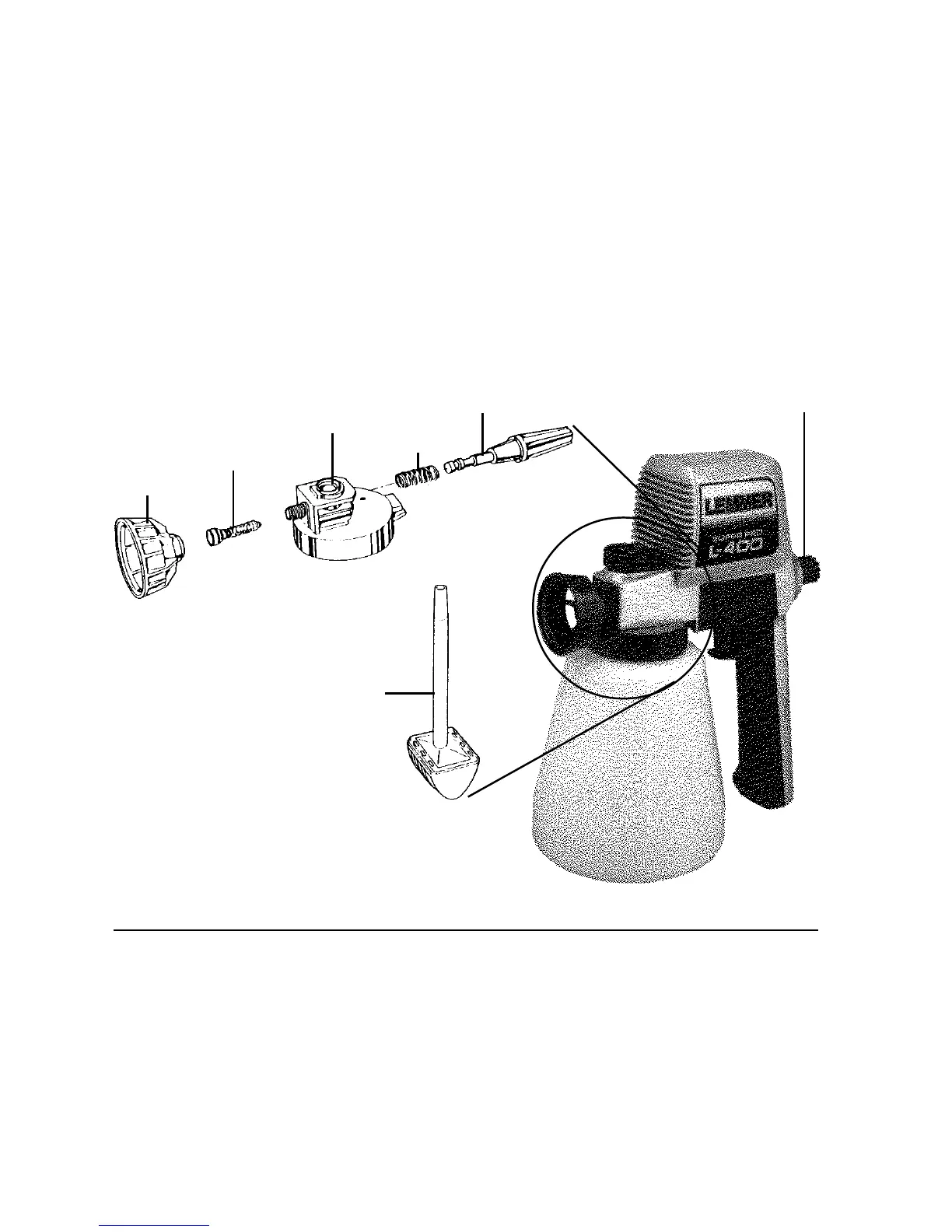

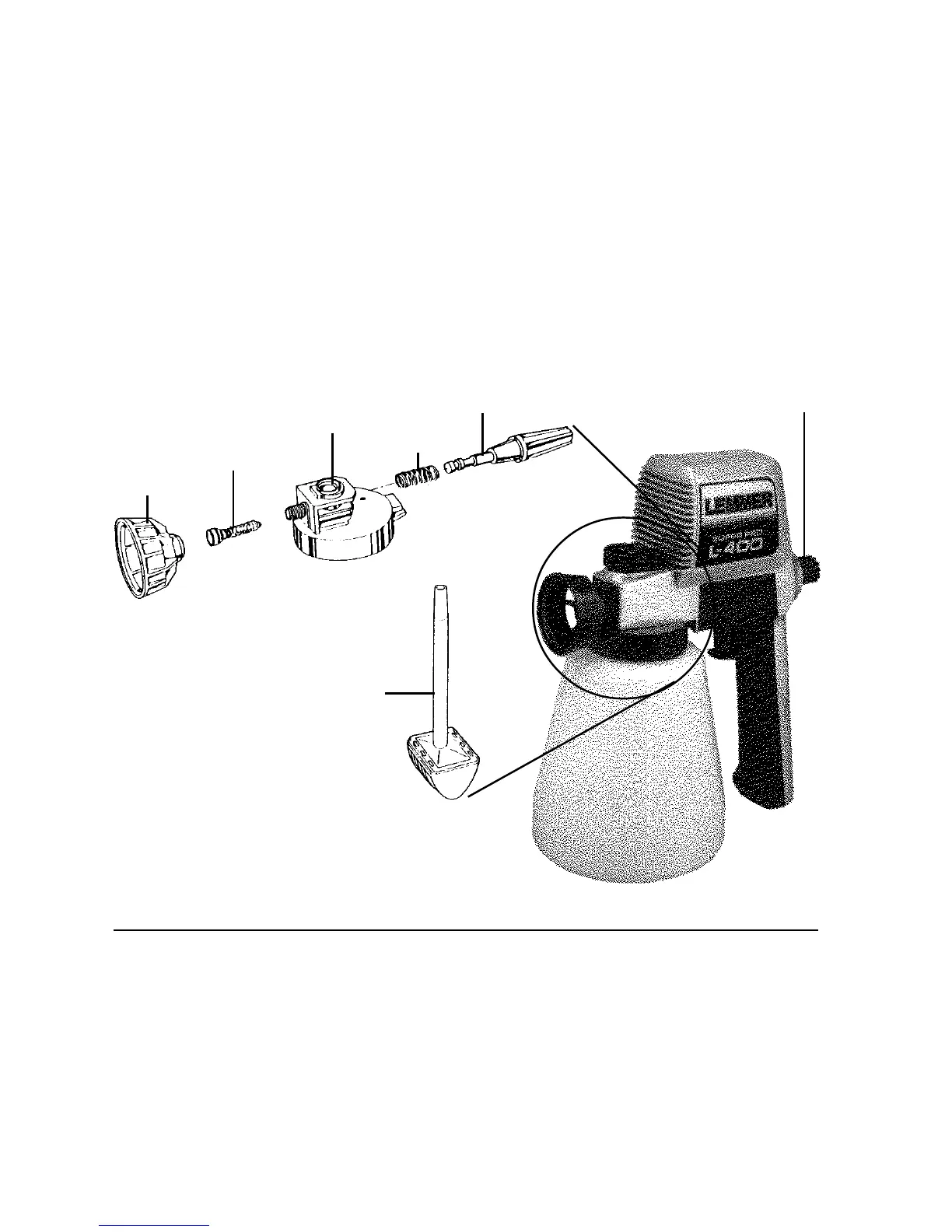

Piston Control knob

Pump Cylinder

Spring

Valve

Nozzle

Suction Tube

TECHNICAL DATA

L-300 L-400

Power .....................................120 VAC/60HZ .............................. 120 VAC/60HZ...........................

Watts ......................................80 W .............................................. 90 W ..........................................

Amps ......................................2.0 A .............................................. 2.0 A ..........................................

Weight ....................................3.3 lbs.(1.5 kg)............................... 3.5 lbs.(1.6 kg) ...........................

Maximum Volume ..................15 min./gal. .................................... 13 min./gal. ................................

Maximum Viscosity ................100 sec. ......................................... 110 sec. .....................................

Cylinder Material ....................Ceramic ......................................... Ceramic .....................................

Piston Material ....................... Grooved tungsten carbide ............. Grooved tungsten carbide .........

Valve Cone ............................Self-centering ceramic ................... Self-centering ceramic ...............

Container ............................... 37 oz (1.1Ltr) ................................. 37 oz (1.1Ltr) .............................

Loading...

Loading...