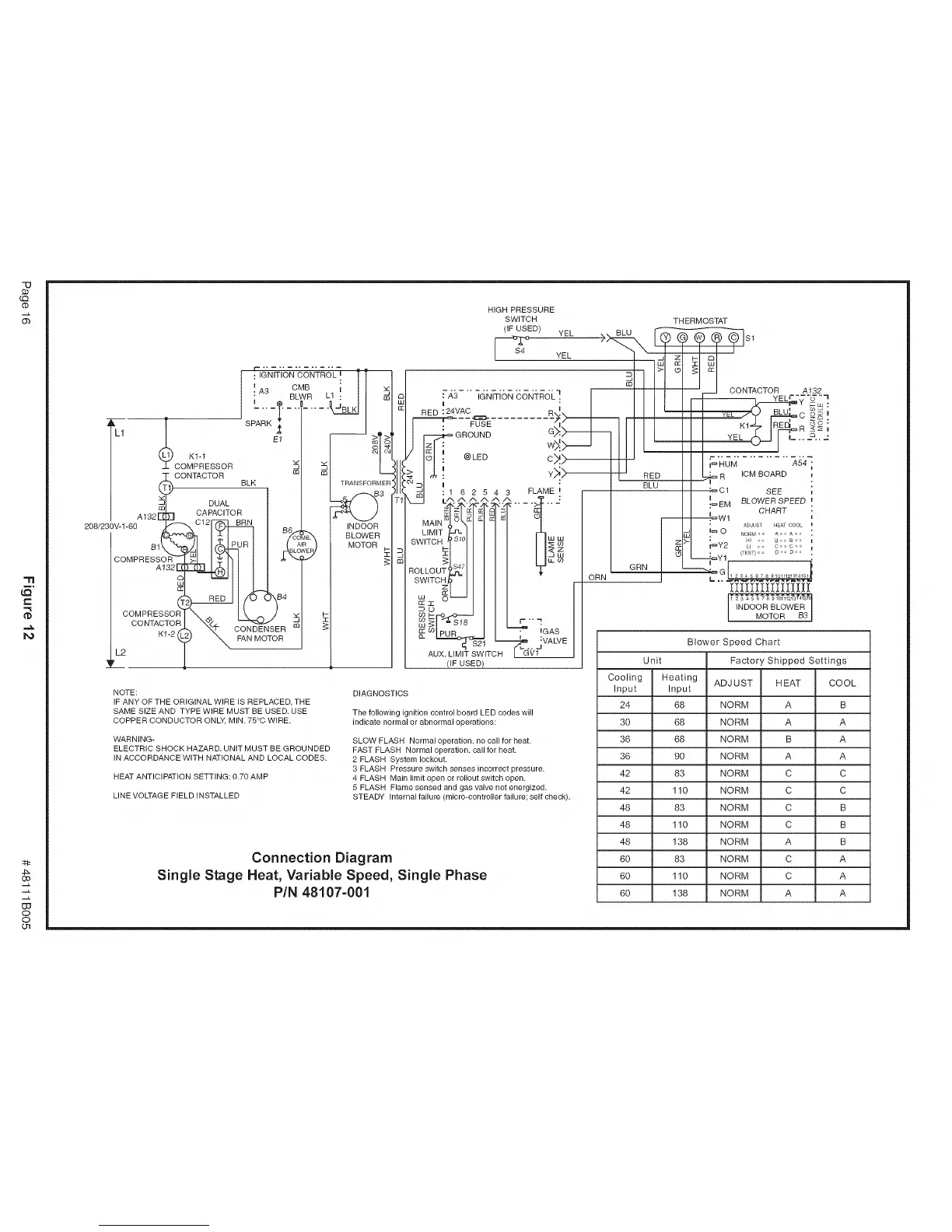

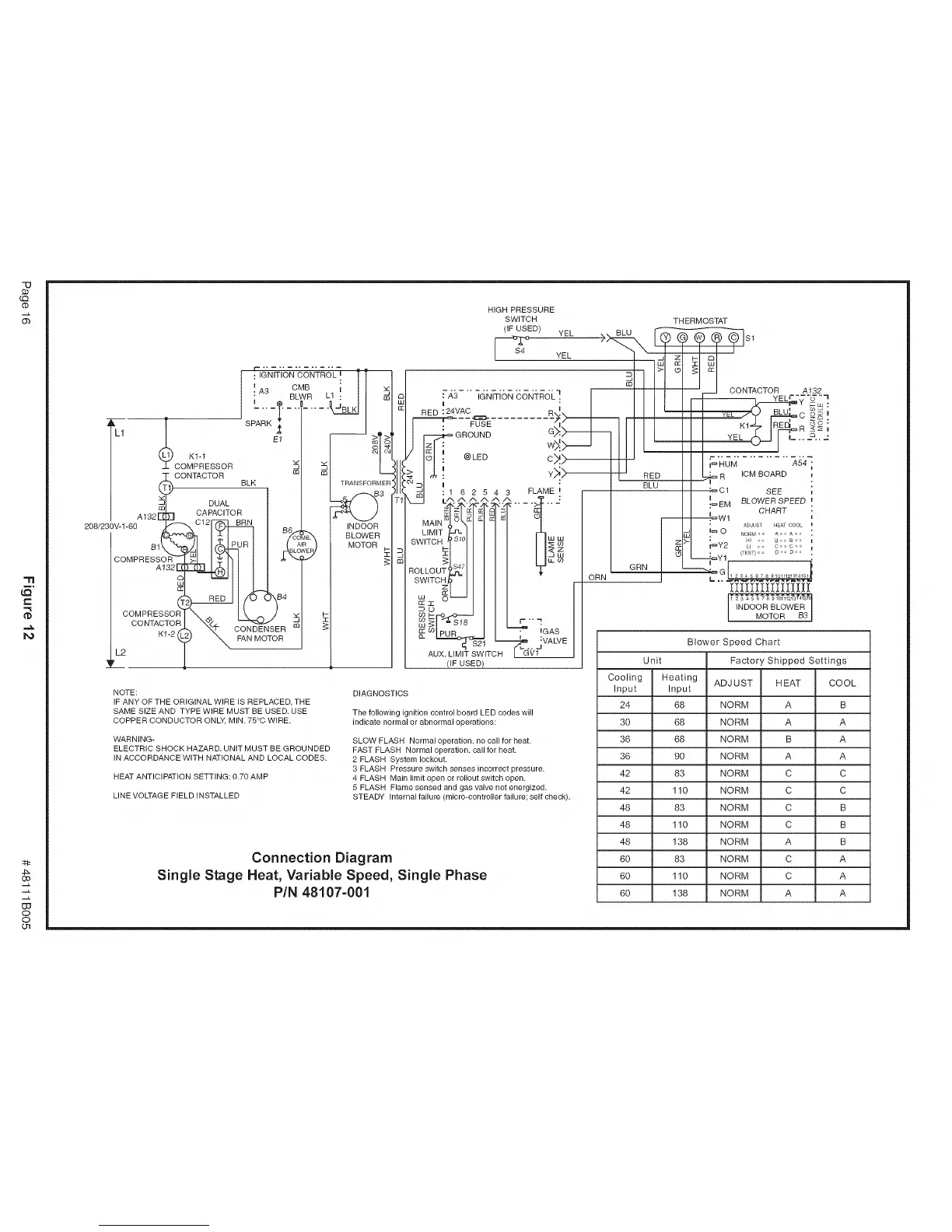

_L1

K1-1

COMPRESSOR

:TI_CONTACTO R

__ _BLK

it DUAL

A1321 ___ CAPACITOR

208/230V-1-60

COMPRESB;ORt_

A1321R

7

CONDENSER

FAN MOTOR

COMPRESSOr

CONTACTOR

K1-2

L2

L

TRANSFORMER

INDOOR

SLOWER

MOTOR

NOTE:

IF ANY OF THE ORIGINAL WIRE IS REPLACED. THE

SAME SIZE AND TYPE WIRE MUST BE USED. USE

COPPER CONDUCTOR ONLY, MIN. 75°C WIRE.

WARNING-

ELECTRIC SHOCK HAZARD. UNIT MUST BE GROUNDED

IN ACCORDANCE WITH NATIONAL AND LOCAL CODES.

HEAT ANTICIPATION SETTING: 0.70 AMP

LINE VOLTAGE FIELD INSTALLED

DIAGNOSTICS

HIGH PRESSURE

SWITCH THERMOSTAT

(IF USED) YEL ): $1

l_ YEL

i

RED :24VAC

FUSE

The following ignition control board LED codes will

indicate normal or abnormal operations:

ORN

GRN

I_HUM A54 ;

ICM BOARD i

SEE i

I BLOWER SPEED i

:=EM

CHART

i

i ADJUST HEAT COOL I

_O NORM o o A Ao "

: (a B ">oB_ I

pY2 0 o c o-, c oo i

(TEST) o D > D,0

L,,

IIIIIIIIIIIIIIII

INDOOR BLOWER |

MOTOR B3J

Blower Speed Chart

Unit Factory Shipped Settings

SLOW FLASH Normal operation, no call for heat.

FAST FLASH Normal operation, call for heat.

2 FLASH System lockout.

3 FLASH Pressure switch senses incorrect pressure.

4 FLASH Main limit open or rollout switch open.

5 FLASH Flame sensed and gas valve not energized,

STEADY Internal failure (micro-controller failure; self check),

Connection Diagram

Single Stage Heat, Variable Speed, Single Phase

PIN 48107-001

Cooling

Input

24

30

36

36

42

42

48

48

48

60

60

60

Heating

Input

68

68

68

90

83

110

83

110

138

83

110

138

ADJUST

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

NORM

HEAT

A

A

B

A

C

C

C

C

A

C

C

A

COOL

B

A

A

A

C

C

B

B

B

A

A

A

Loading...

Loading...