507266-05 Page 45 of 58Issue 1933

Emergency Replacement Motor Operation

If the variable speed motor needs to be replaced in an

emergency situation (such as “no heat”) and an exact

replacement motor is not immediately available, a standard

PSC motor of equivalent frame size, voltage, rotation, and

horsepower can be temporarily installed until the correct

replacement motor can be obtained.

Connect the desired speed tap to the “ACC” terminal and

the neutral tap to the neutral terminal on the ignition control

(refer to the furnace wiring diagram). The ignition control

will control the motor’s operation, including a nominal 20

second “on” delay with a call for heat and a nominal 180

second “o” delay when the thermostat is satised. It will

also operate the motor on a call for cooling, with no “on” or

“o” delays.

Verify that the unit is operating at the desired speed and

within the rise range as shown on the unit rating plate.

The correct replacement motor must be installed as soon

as possible to ensure continued satisfactory operation of

the furnace.

Control Diagnostics

Troubleshooting

Make the following visual checks before troubleshooting:

1. Check to see that the power to the furnace and the

integrated ignition/blower control board is ON.

2. The manual shuto valves in the gas line to the furnace

must be open.

3. Make sure all wiring connections are secure.

4. Review the Sequence of Operation.

Start the system by setting thermostat above room

temperature. Observe system response. Then use the

information provided in this section to check the system

operation.

The furnace has a built-in, self-diagnostic capability. If a

system problem occurs, a fault code is shown by a red LED

on the control board. The control continuously monitors its

own operation and the operation of the system. If a failure

occurs, the LED will indicate the failure code. The ash

codes are presented in Table 10.

Fault Code History Button

The control stores the last ve fault codes in memory. A

push-button switch is located on the control. When the

push-button switch is pressed and released, the control

ashes the stored fault codes. The most recent fault code

is ashed rst; the oldest fault code is ashed last. To clear

the fault code history, press and hold the push-button

switch in for more than 5 seconds before releasing.

High Heat State LED

On 95G2UHV models, a green LED is provided on the

control board to indicate high heat state (see Table 11).

CFM LED

On 95G2UHV models equipped with a variable speed

motor, an amber LED is provided on the control board to

display CFM. To determine what CFM the motor is delivering

at any time, count the number of times the amber LED

ashes. Each ash signies 100 CFM; count the ashes

and multiply by 100 to determine the actual CFM delivered

(for example: 10 ashes x 100 = 1000 CFM).

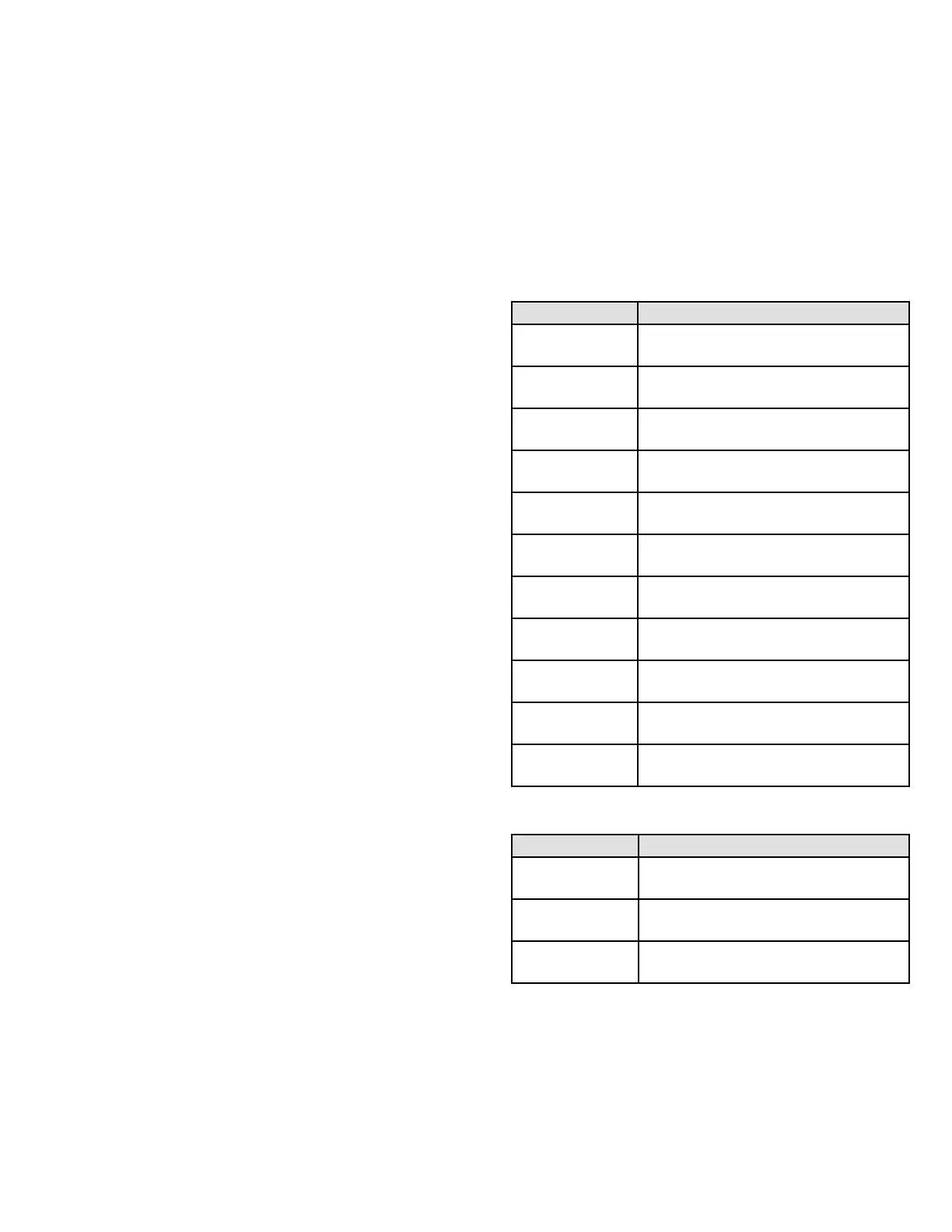

Table 10. Failure Codes - Red LED

LED Status Fault Description

LED O

No power to control or control hardware

fault detected

LED On Normal operation

1 Flash Flame present with gas valve o

2 Flashes Pressure switch closed with inducer o

3 Flashes

Low-re pressure, rollout, or aux limit

switch open

4 Flashes High limit switch open

5 Flashes Not used

6 Flashes Pressure switch cycle lockout

7 Flashes Lockout due to no ignition

8 Flashes Lockout due to too many ame dropouts

9 Flashes Incorrect polarity and phasing

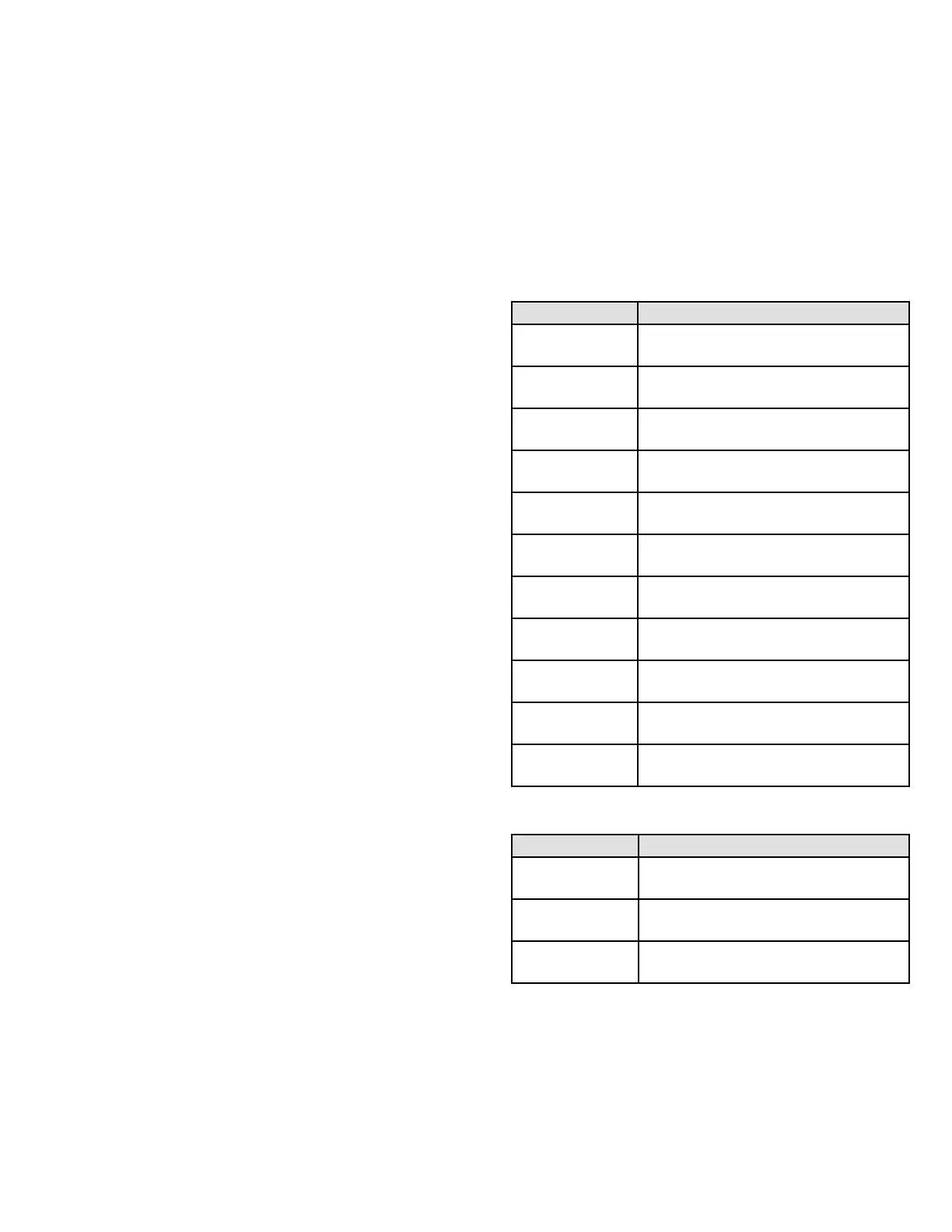

Table 11. High Heat State - Green LED

LED Status Description

LED O No demand for high heat

LED On High heat demand, operating normally

LED Flashing

High heat demand, high pressure switch

not closed

Loading...

Loading...