Page 15

7. Make sure outdoor unit has been put in place according

to the Installation Instructions and is connected to the

refrigerant lines.

RELOCATING TXV BULB

Relocation of the TXV bulb to the exterior of the unit cabinet

is highly recommended. Use the following procedure to

perform this task.

1. Remove unit access panel.

2. Locate factory installed TXV bulb.

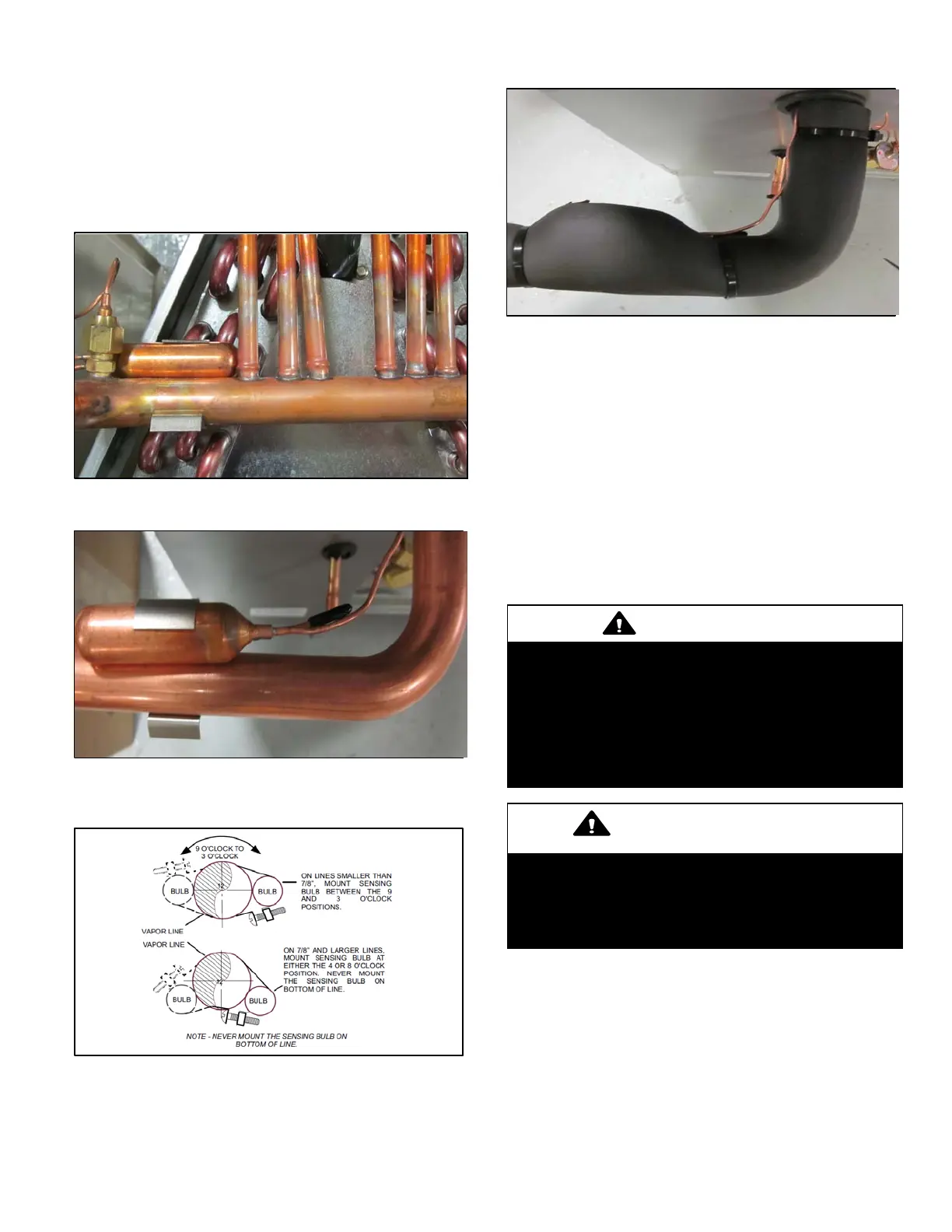

Figure 25. Factory Installed Location

3. Relocate TXV bulb to external suction line.

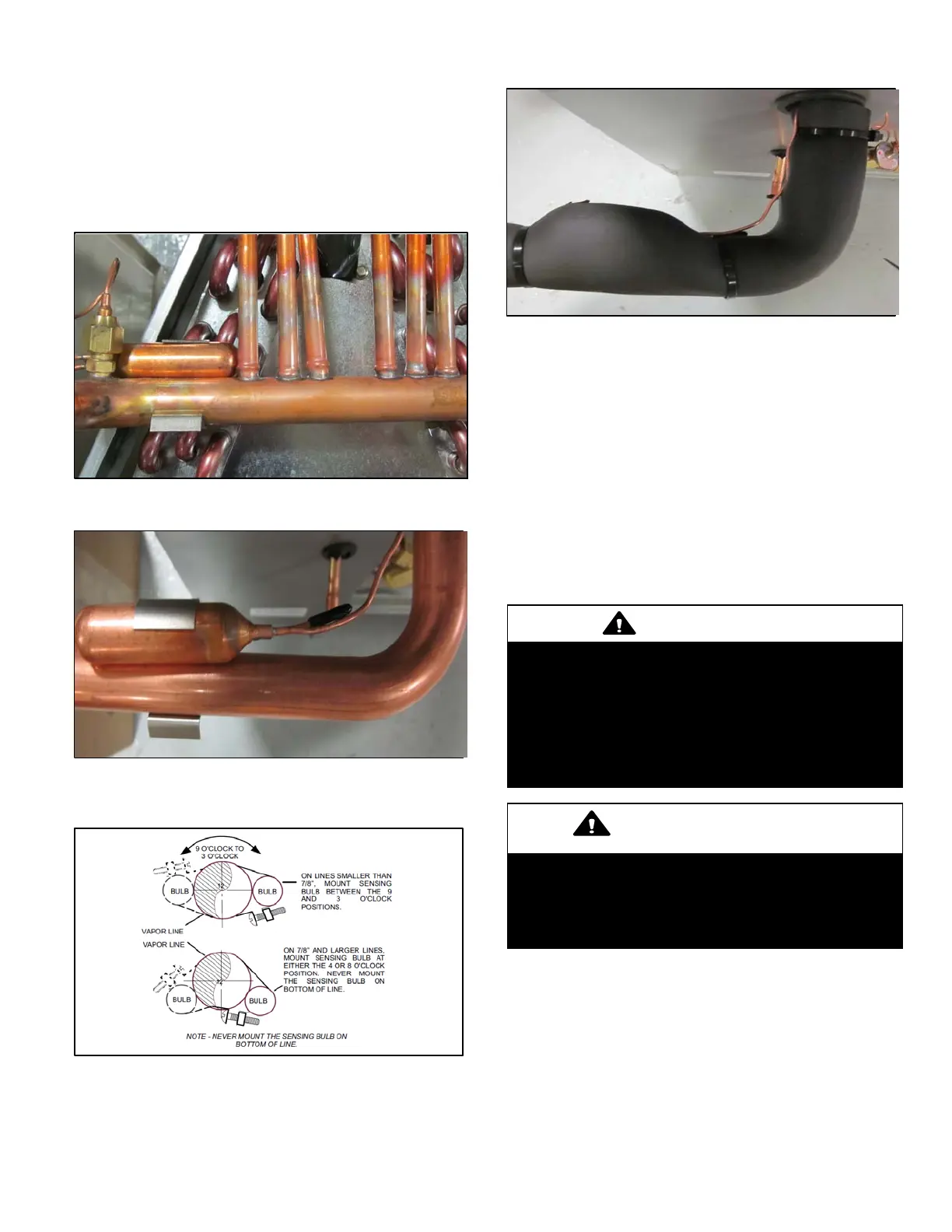

Figure 26. External Suction Line

4. Mount and fasten TXV bulb on suction line as indicated

below.

Figure 27. Sloping the Drain

5. Apply insulation over the suction line and TXV bulb and

secure with tape or cable ties..

Figure 28. Insulation

Note: Route copper away from sharp edges and make

sure that copper refrigerant tubing does not touch other

metal surfaces (end plates, brazed connections, etc.)

where damage may be caused by vibration, or by

movement of metal against metal.

SEALING THE UNIT

Seal the unit so that warm air is not allowed into the cabinet.

Warm air introduces moisture, which results in water

blow-off problems. This is especially important when the

unit is installed in an unconditioned area.

If installed in an unconditioned space, sealant should be

applied around the electrical wires, refrigerant tubing, and

condensate lines where they enter the cabinet.

WARNING

There must be an airtight seal between the bottom of the

air handler and the return air plenum. Use fiberglass

sealing strips, caulking, or equivalent sealing method

between the plenum and the air handler cabinet to ensure

a tight seal. Return air must not be drawn from a room

where this air handler or any gas-fueled appliance (i.e.,

water heater), or carbon monoxide-producing device

(i.e., wood fireplace) is installed.

IMPORTANT

When sealing the cabinet, be sure to seal closed any

space around the holes where the drain lines exit the cab

inet using duct tape and/or Permagum. Warm air must not

be allowed to enter through any gaps or holes in the cabi

net.

Make sure the liquid line and suction line entry points are

sealed with either ARMAFLEX material or with Permagum.

Permagum may also be used to seal around the main and

auxiliary drains and around open areas of electrical inlets.

Loading...

Loading...