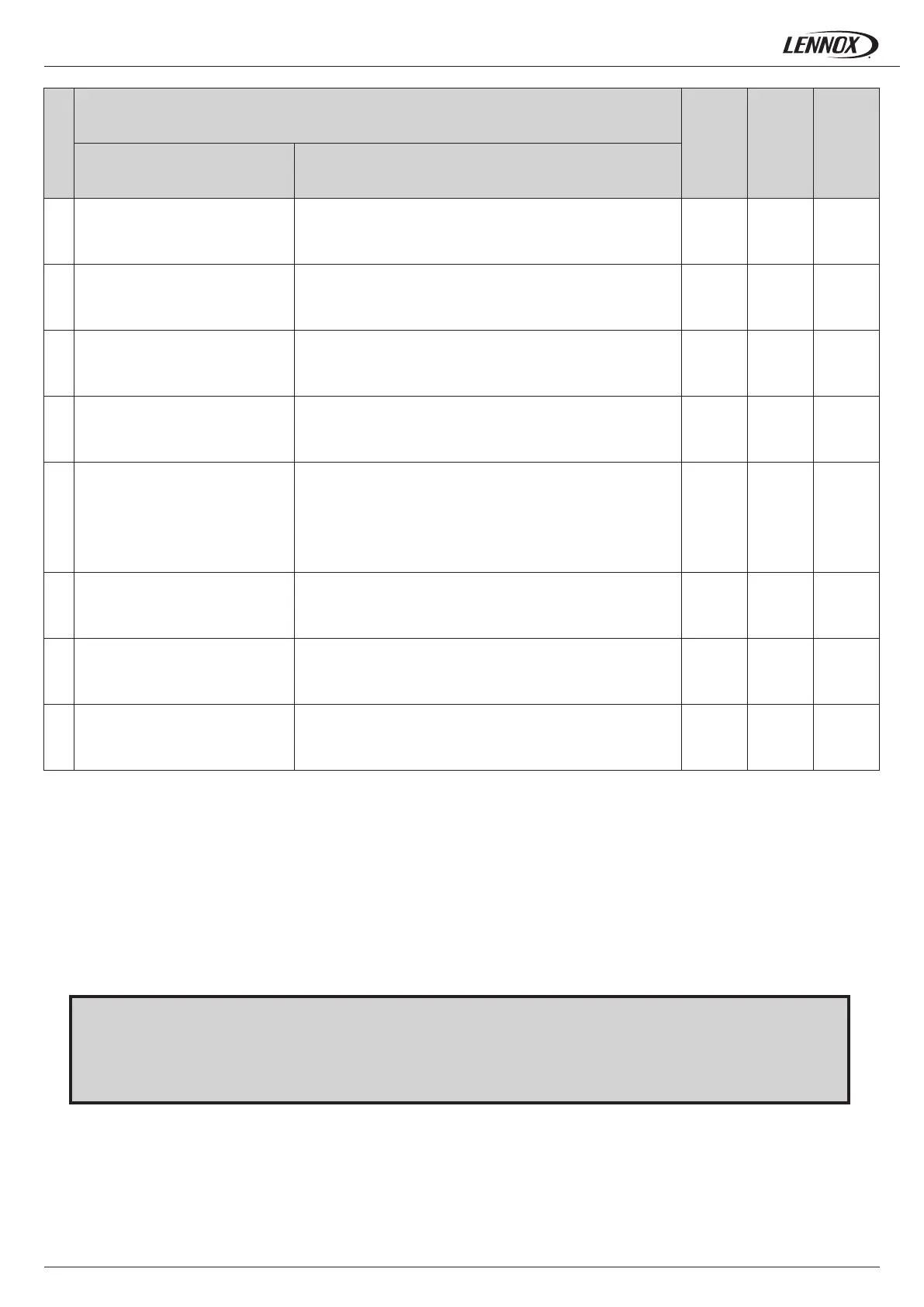

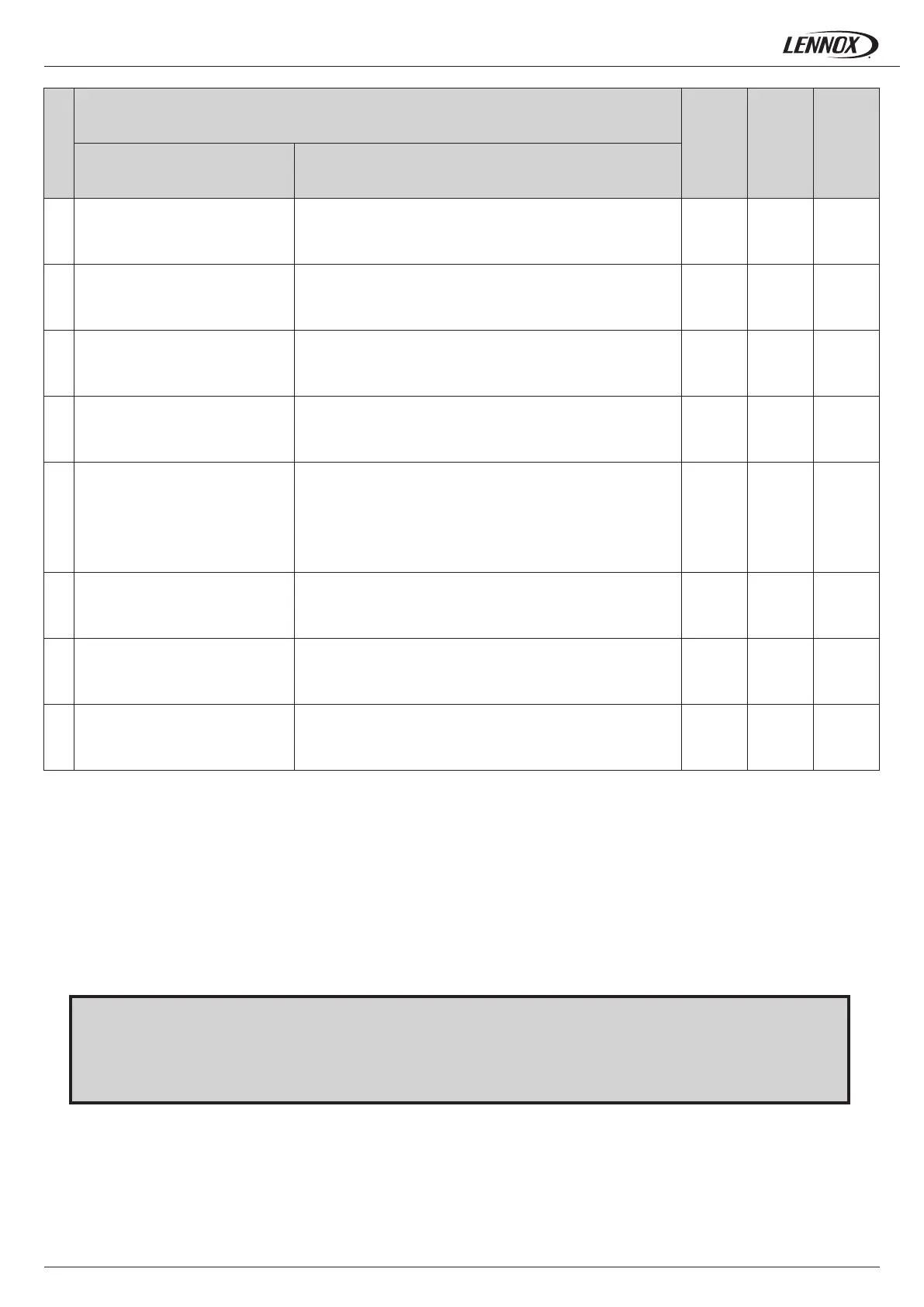

• 78 •

25 •

26 •

27 |

28 •

29 |

30 |

31 |

32 |

Installation manual / eCOMFORT R32-MIL166E-0222 - 09/2022

N°

MAINTENANCE PLAN

Monthly

+ Quarterly

Half Yearly

Task Operating mode

Check the position of all sensors. Check the position and the xation of all sensors.

Check anti-vibration mountings, for

wear and tear.

Visually check anti-vibration mountings on compressors and centrifu-

gal fan. Replace it, if damaged.

Check glycol concentration in the wa-

ter circuit.

Check the glycol concentration in the pressurized water circuit. (

a concentration of 30% gives a protection down to approx.. -15°C)

check the circuit pressure.

Check casing and equipment

corrosion.

To treat and neutralize eventuals rust spots.

Check the water pump.

When the unit is operated with glycol up to 20% and the water tem-

perature below -5°C, even if you use a specic thermal protection

for the pump, it is advisable to clean the body of the pump every

18 months in order to avoid leaks by crystallization. (see supplier

catalogue).

Plate exchanger.

Verify the general insulation state, the tightness of the water connec-

tion and the freeze protection.

Check the expansion vessel (if

applicable).

Measure the pressure under the dierent water modes ( from +7°C to

+45°C).

Check the software version. Contact the manufacturer for updates.

It is therefore advisable to ask your dealer about maintenance contracts. Local legislation must be respected.

When carrying out maintenance works on these units, please make a correct segregation of the non-hazardous waste generated

- insulation, air lters, plastic or metallic elements, packaging, etc. - as well as waste considered hazardous: oil lters and rags

impregnated with oils, welding elements such as ller material, strippers, electrical and electronic waste, batteries, lamps, etc. They

must be managed by an authorized dealer.

The refrigerant gas can be reused, or collected in a bottle and managed as hazardous waste by an authorized dealer.

Symbols and legends:

● Operation which can be carried out by on-site maintenance technicians.

▌Operation which must be carried out by qualied refrigeration personnel, trained to operate on this type of

equipment.

Loading...

Loading...