Page 47

Blower Speeds

Follow the steps below to change the blower speeds.

1 - 7XUQRႇHOHFWULFDOSRZHUWRIXUQDFH

2 - Remove blower access panel.

3 - Disconnect existing speed tap at integrated control

speed terminal.

NOTE - 7HUPLQDWLRQRIDQ\XQXVHGPRWRUOHDGVPXVWEH

LQVXODWHG

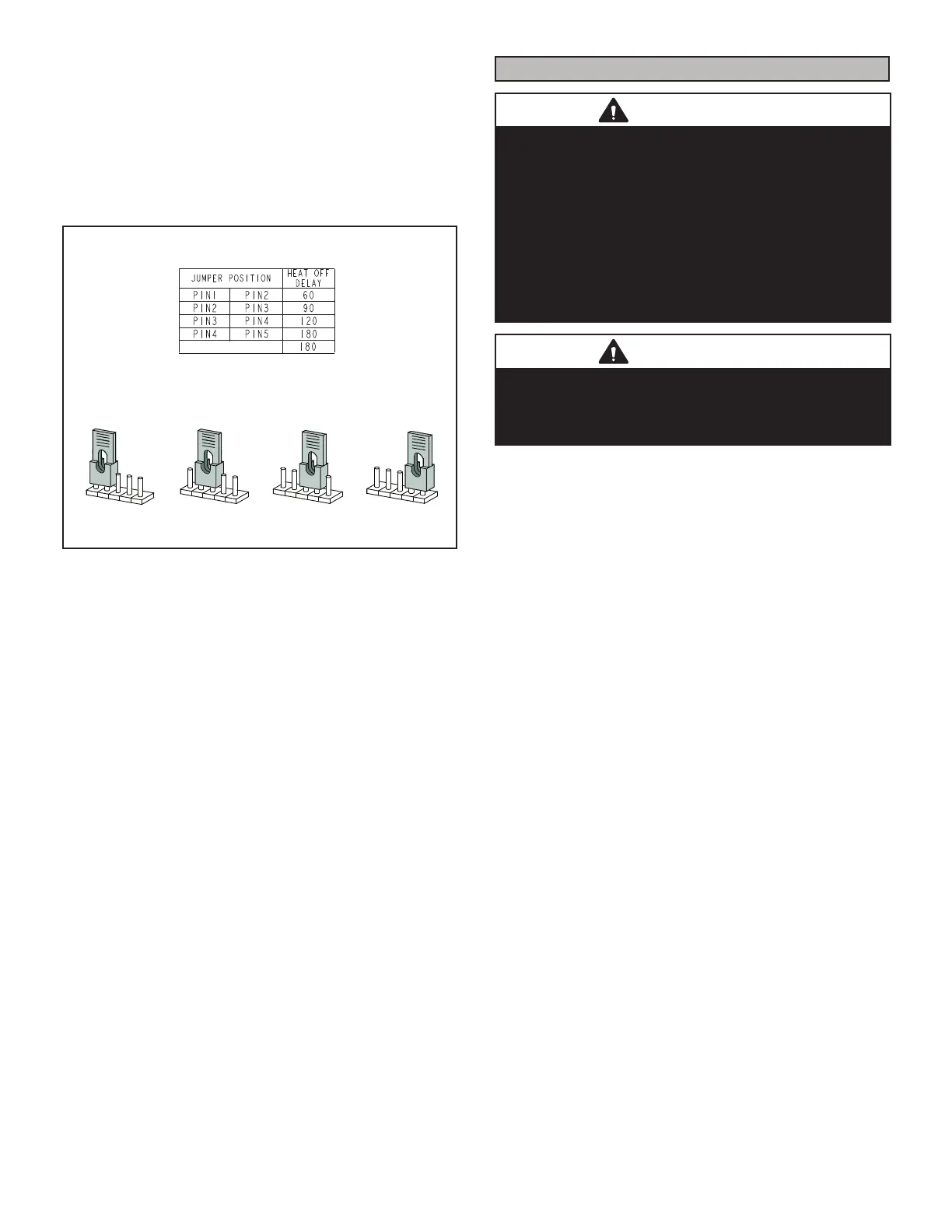

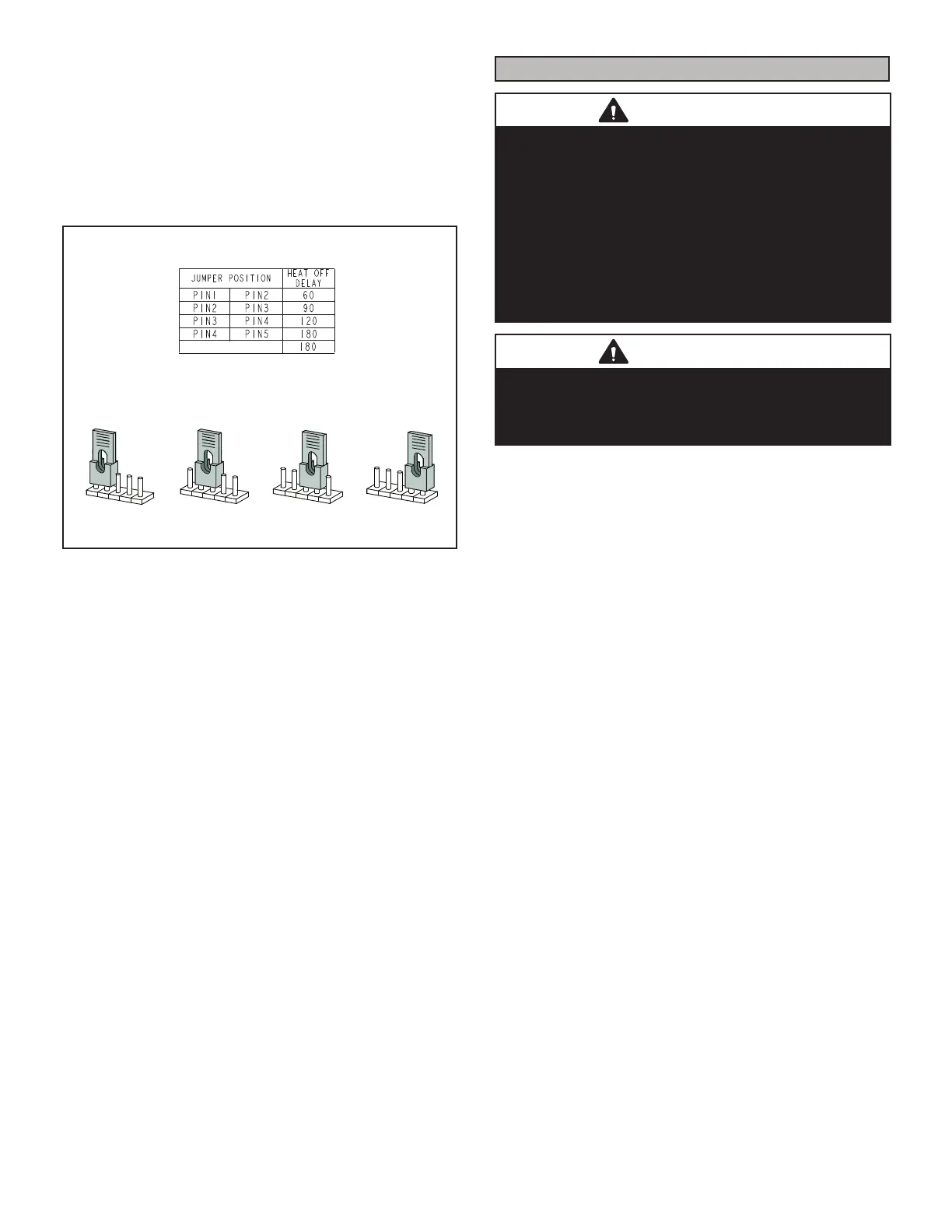

HEAT FAN‐OFF TIME IN SECONDS

To adjust fan-off timing, reposition jumper across pins to

achieve desired setting.

NO JUMPER

60

90

120

180

60

90

120

180

60

90

120

180

60

90

120

180

60 Second

off Time

90 Second

off Time

120 Second

off Time

180 Second

off Time

Figure 62

4 - Place unused blower speed tap on integrated control

“PARK” terminal or insulate.

5 - Refer to blower speed selection chart on unit wiring

diagram for desired heating or cooling speed. See

TABLE 17 on page 54 for allowable heating

speeds.

6 - Connect selected speed tap at integrated control

speed terminal.

7 - Resecure blower access panel.

8 - Turn on electrical power to furnace.

9 - Recheck temperature rise.

Electronic Ignition

The integrated control has an added feature of an internal

Watchguard control. The feature serves as an automat-

ic reset device for integrated control lockout caused by

ignition failure. This type of lockout is usually due to low

gas line pressure. After one hour of continuous thermostat

demand for heat, the Watchguard will break and remake

thermostat demand to the furnace and automatically reset

the integrated control to begin the ignition sequence.

Exhaust and Air Intake Pipe

1 - Check exhaust and air intake connections for

tightness and to make sure there is no blockage.

2 - Is pressure switch closed? Obstructed exhaust pipe

ZLOOFDXVHXQLWWRVKXWRႇDWSUHVVXUHVZLWFK&KHFN

termination for blockages.

3 - Obstructed pipe or termination may cause rollout

VZLWFKHV WR RSHQ 5HVHW PDQXDO ÀDPH UROORXW

switches on burner box assembly if necessary.

Service

WARNING

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could result in

dangerous operation, serious injury, death or property

damage. Improper servicing could result in dangerous

operation, serious injury, death, or property damage.

Before servicing, disconnect all electrical power to

furnace. When servicing controls, label all wires prior to

disconnecting. Take care to reconnect wires correctly.

Verify proper operation after servicing.

WARNING

The blower access panel must be securely in place when

the blower and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into living

space resulting in personal injury or death.

Annual Furnace Maintenance

At the beginning of each heating season, and to comply

with the Lennox Limited Warranty, your system should be

checked as follows:

1 - Check wiring for loose connections, voltage at

indoor unit and amperage of indoor motor.

2- Check the condition of the belt and shaft bearings if

applicable.

3- Inspect all gas pipe and connections for leaks.

&KHFN WKH FOHDQOLQHVV RI ¿OWHUV DQG FKDQJH LI

necessary (monthly).

5- Check the condition and cleanliness of burners and

heat exchanger and clean if necessary.

6- Check the cleanliness of blower assembly and

clean the housing, blower wheel and blower motor if

necessary.

7- Inspect the condensate drain and trap for leaks and

cracks. The drain and trap must also be cleaned

and the trap must be primed with water. Inspect the

rubber hoses connected to the pressure switches for

cracks or loose connections, replace as necessary.

Remove the rubber hoses from the cold end header

box and inspect for any blockage, clean as needed.

If strainers are installed in the hoses remember to

remove and clean before reinstalling the hoses.

8- Evaluate the heat exchanger integrity by inspecting

the heat exchanger per the AHRI heat exchanger

inspection procedure. This procedure can be viewed

at www.ahrinet.org

(QVXUH VXႈFLHQW FRPEXVWLRQ DLU LV DYDLODEOH WR WKH

furnace. Fresh air grilles and louvers (on the unit and

in the room where the furnace is installed) must be

SURSHUO\ VL]HG RSHQ DQG XQREVWUXFWHG WR SURYLGH

combustion air.

Loading...

Loading...