Page 48

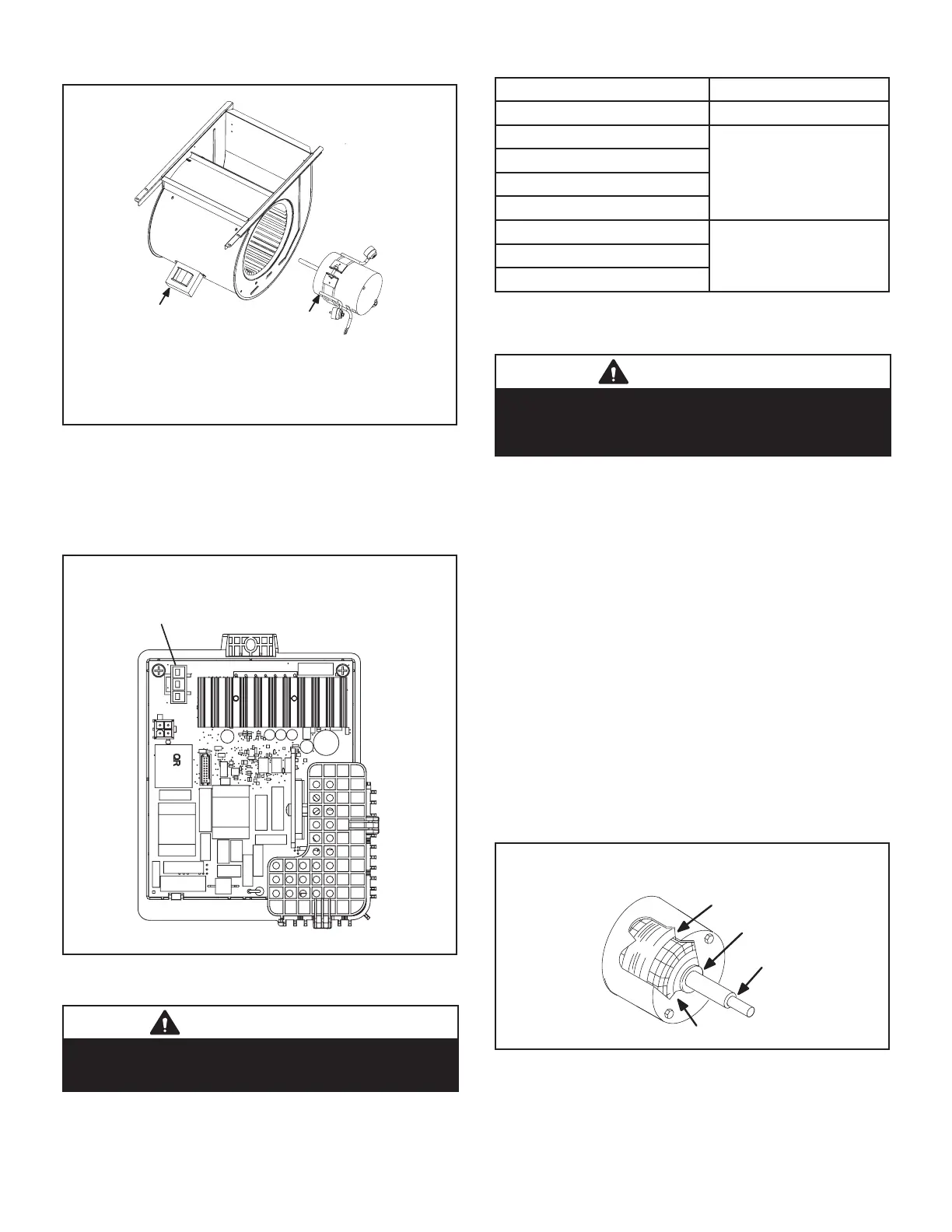

B- Indoor Blower Motor

Power Choke

(4 and 5 Ton Only)

Blower Motor

(B3)

To Remove Blower From Unit: Remove access panels,

Control box, Bolts and Wiring Jackplugs.

Then Slide Out Front of Unit.

FIGURE 7

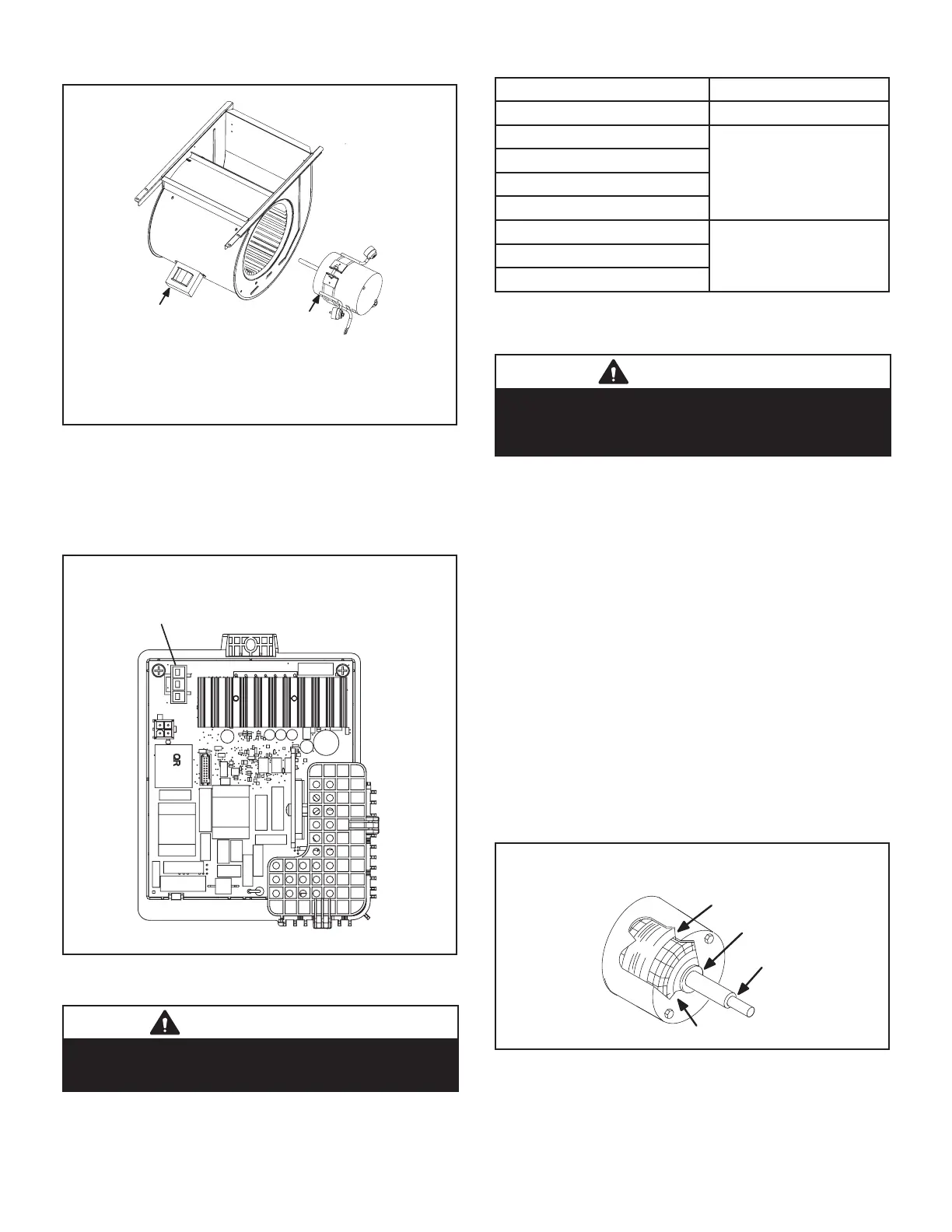

Blower Drive

Some EL297UHV units will be equipped with a blower

drive shown in FIGURE 8 with LED codes for operation

in TABLE 12. The blower drive is not repairable. If it fails

replace the drive.

BLOWER DRIVE

Located in the control box

Three pin connector to

blower motor

FIGURE 8

IMPORTANT

Earlier ECM motors used on other Lennox furnace

models are not interchangeable with motors used

on the EL297UH furnace line.

TABLE 12

Led* Meaning

1 short blink Normal heartbeat

2 short blinks

Drive fault

replace drive

3 short blinks

4 short blinks

5 short blinks

1 long blink + 1short blink

Temporary fault

(see troubleshooting

page 52)

1 long blink + 2 short blinks

1 long blink + 3 short blinks

* Do not touch or remove drive for replacement until all

blinking lights are o. Blinking light(s) indicates drive still

has power.

WARNING

During blower operation, the ECM motor emits

energy that may interfere with pacemaker operation.

Interference is reduced by both the sheet metal

cabinet and distance.

The motor communicates with the integrated control via

a 2-way serial connection. The motor receives all neces-

sary functional parameters from the integrated control and

does not rely on a factory program like traditional variable

speed motors. EL297UHV units use a three-phase, elec-

tronically controlled D.C. brushless motor (controller con-

verts single phase a.c. to three phase D.C.), with a perma-

nent-magnet type rotor (FIGURE 9). Because this motor

has a permanent magnet rotor it does not need brushes

like conventional D.C. motors.

The stator windings are split into three poles which are

electrically connected to the controller. This arrangement

allows motor windings to turn on and o in sequence by

the controller.

A solid-state controller is permanently attached to the mo-

tor. The controller is primarily an A.C. to D.C. converter.

Converted D.C. power is used to drive the motor. The con-

troller contains a microprocessor which monitors varying

conditions inside the motor (such as motor workload).

STATOR

(WINDINGS)

OUTPUT

SHAFT

BEARING

FIGURE 9

Loading...

Loading...