Page 28

Switches 11 and 12 −− Heating Mode Blower Speed −−

Switches 11 and 12 are used to select heating mode blower

motor speed. The unit is shipped from the factory with the

dip switches positioned for medium low (2) speed indoor

blower motor operation during the heating mode. The table

below provides the heating mode blower speeds that will

result from different switch settings. Refer to blower data

tables at the front of this manual for corresponding cfm val-

ues.

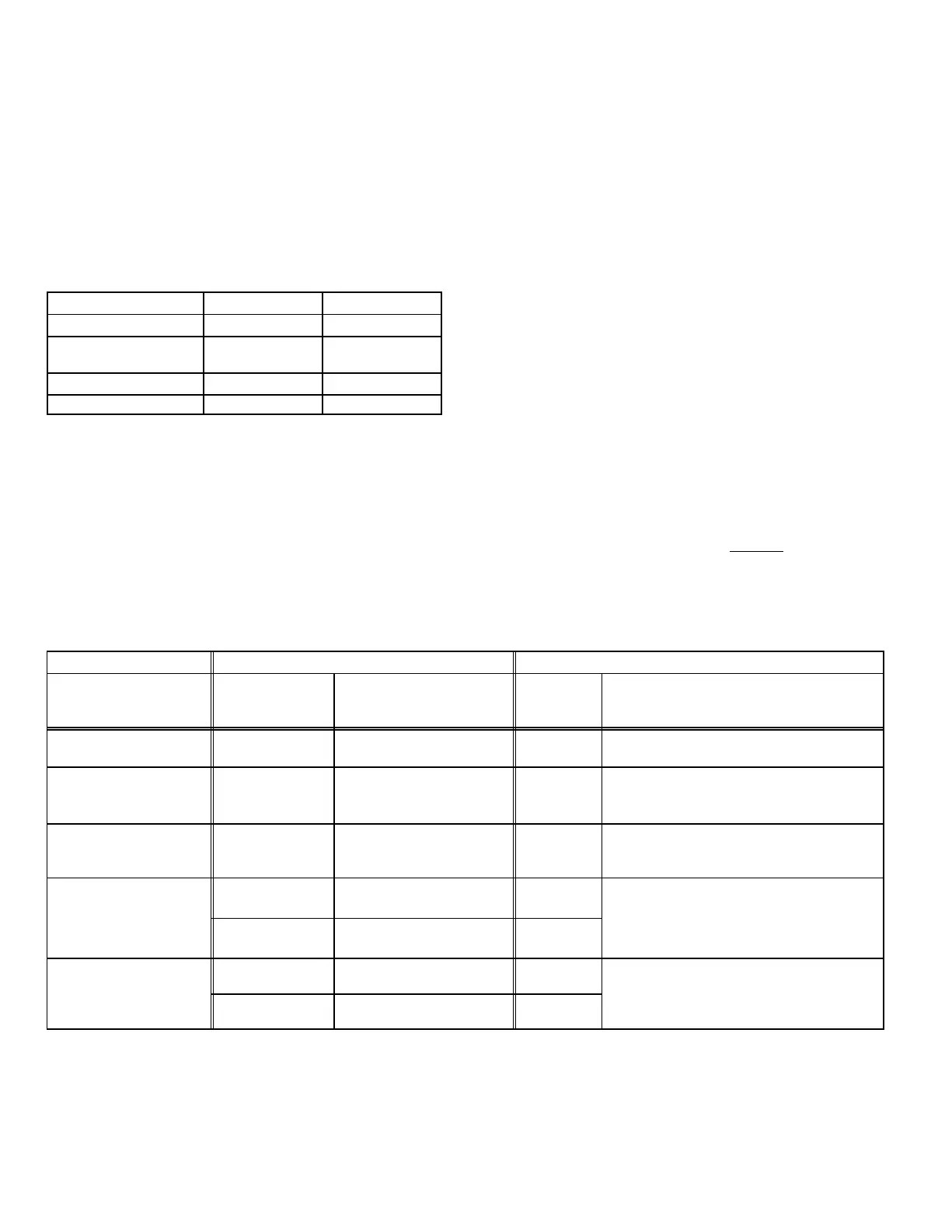

TABLE 26

Heating Mode Blower Speeds

Speed

Switch 11 Switch 12

1 − Low On On

2 − Medium Low

(Factory)

Off On

3 − Medium High On Off

4 − High Off Off

On−Board Jumper W914

On−board jumper W914, which connects terminals DS and

R on the integrated control board, must be cut when the fur-

nace is installed with either the Harmony II zone control

board or the CCB1 EfficiencyPlus humidity control. Refer to

table 27 for operation sequence in applications including a

G32V, CCB1 and single−speed outdoor unit. Table 28 gives

the operation sequence in applications with a two−speed

outdoor unit.

On−Board Jumper W951

On−board jumper W951, which connects terminals R and O

on the integrated control board, must be cut when the fur-

nace is installed in applications which include a heat pump

unit and the FM21 FuelMaster control board.

On−Board Jumper W915

On board jumper W915, which connects Y1 to Y2 terminals

on the integrated control board terminal strip must be cut if

two−stage cooling will be used.

On−Board Jumper W6

On board jumper W6 is an external measuring device for in-

door blower CFM. If by chance W6 is cut, the CFM LED will

not operate but the furnace will operate as normal. The

jumper has no affect on furnace operation.

Diagnostic LEDs (DS1 and DS2)

Two diagnostic LEDs are located on the two−stage, variable

speed integrated control just to the left of the first bank of dip

switches. These lights’ flashes correspond with diagnostic

codes detailed on in table 21.

Status LEDs (HEAT, HI/LO, ON/OFF and CFM)

The integrated control includes four LEDs which indicate

operating status. The green ON/OFF LED is lit any time the

blower is operating. The green CFM LED indicates the

blower motor speed. Count the number of blinks between

the two−second pauses to determine the CFM. Each blink

represents approximately 100 CFM. The yellow HI/LO LED

is lit when the W914 (DS to R) jumper has not

been clipped

for CCB1 or Harmony operation. The yellow HEAT LED is lit

when the indoor blower is operating at the HEATING

speed.

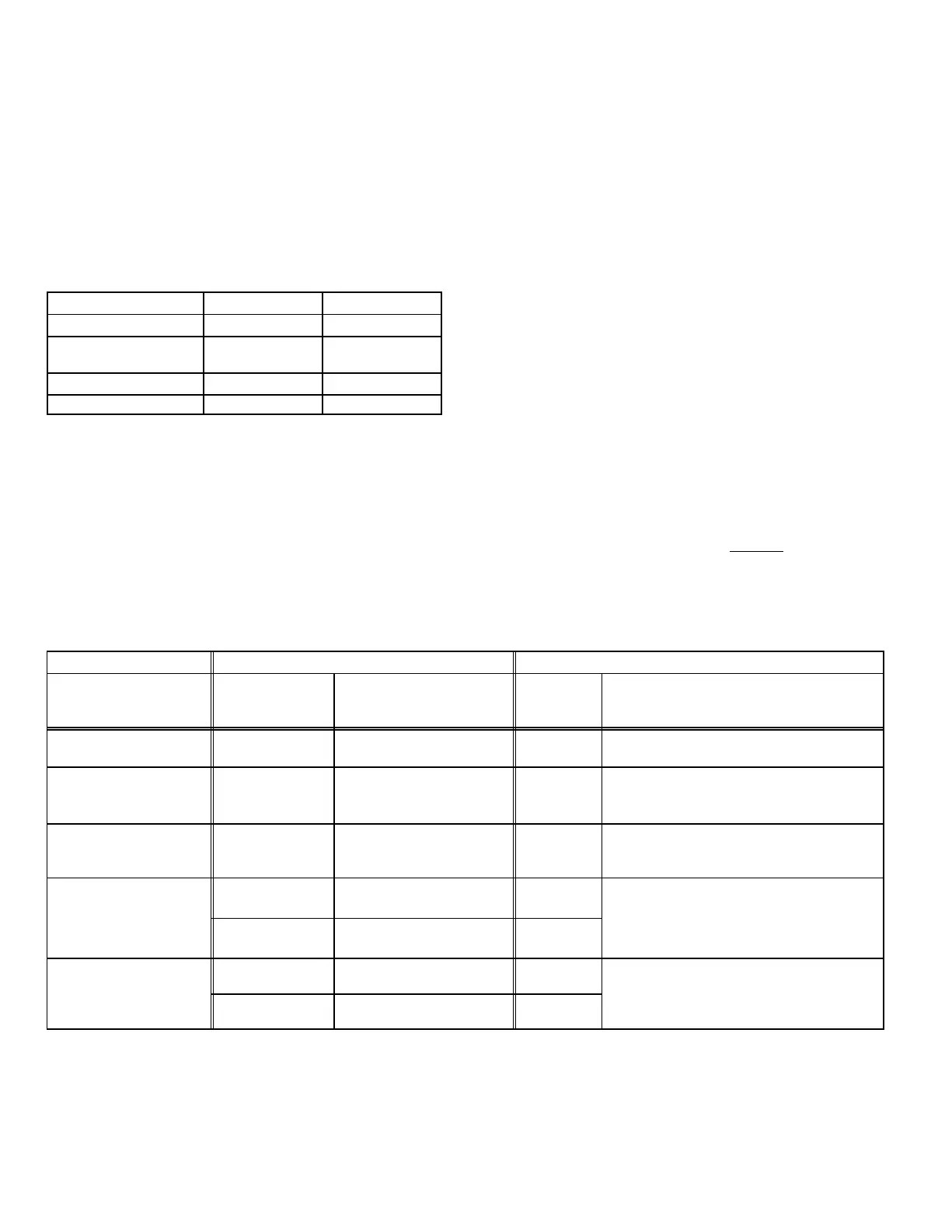

TABLE 27

G32V−5, CCB1 and Single−Speed Outdoor Unit

OPERATING MODE SYSTEM DEMAND SYSTEM RESPONSE

System Condition

Thermostat

Demand

*Relative Humidity

(EfficiencyPlus Lights)

Blower

CFM

(COOL)

Comments

Normal operation Y1

No demand. Humidity

level is acceptable

COOL

Compressor demand and indoor blower

speed controlled by thermostat demand.

*Call for humidity

removal during

cooling demand

Y1

Humidity level rises

above setpoint. Demand

initiated.

77%/74%

of COOL

Call for dehumidification initiated by CCB1

control. Indoor blower speed reduced by

CCB1 control.

Dehumidification

demand satisfied

during cooling demand.

Y1

Humidity level falls below

setpoint. No demand

COOL

When humidity demand is satisfied, blow-

er speed immediately increases to the

COOL CFM to hasten the end of the cycle.

Call for cooling after

None

Humidity level above set-

point. Demand initiated.

Off

Dehumidification mode begins when rela-

ca

or

um

y

removal.

Y1

Humidity level above set-

point. Demand initiated.

77%/74%

of COOL

tive humidity is greater than setpoint.

Humidity demand

satisfied between

None Over setpoint (1 or more) Off

While unit is not operating (no thermostat

demand) slide switch is moved down and

thermostat demands

(unit off cycle).

Y1 Change to acceptable COOL

eman

, s

e sw

c

s move

own an

back up. Blower operates at COOL CFM.

NOTE − When changing unit mode of operation from cooling to heating, indicating lights that are on will stay on until the first ther-

mostat heating demand.

* Reduced blower speed is 77% of COOL for V3 units and 74% of COOL for the V5 units.

Loading...

Loading...